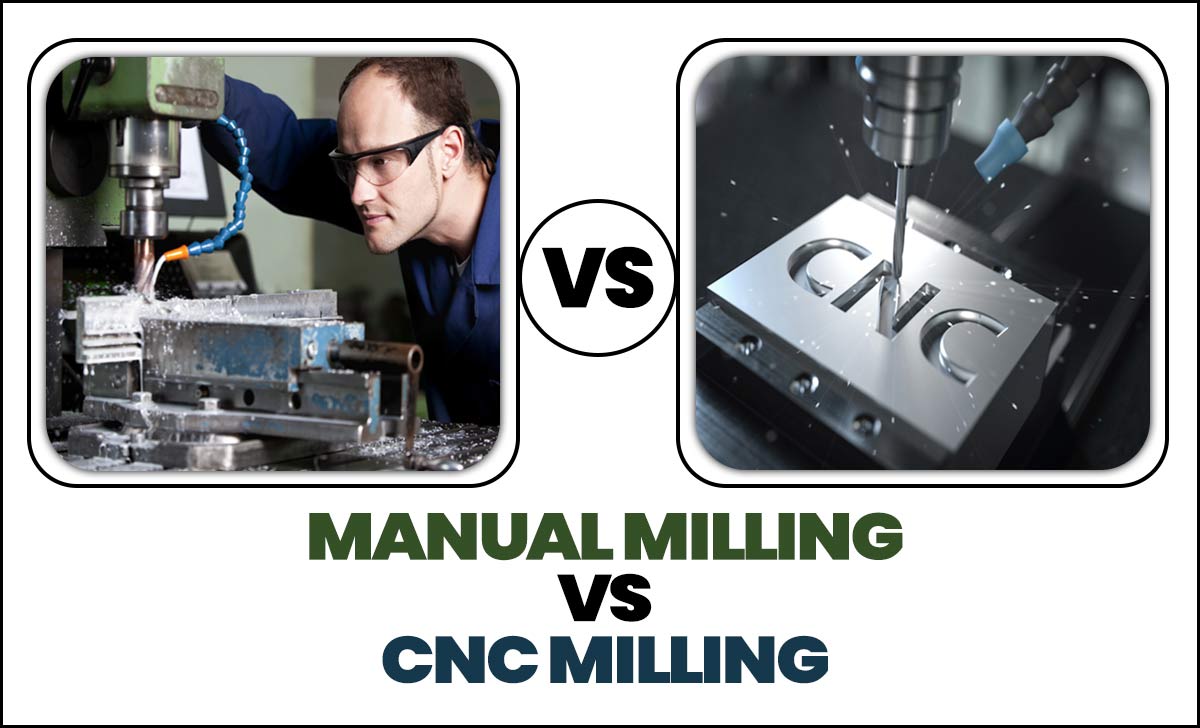

Have you ever wondered how metal parts are shaped and refined? This magic often happens with tools called milling cutters. When working with soft metals like brass and copper, the right milling cutter makes a big difference.

Imagine you’re a craftsman, carefully shaping a piece of brass. You want a smooth finish and precise cuts. A good milling cutter for brass and copper can help you achieve that. Did you know that these cutters can create intricate designs and details? It’s true!

Whether you’re making jewelry or custom parts, using the right tool is key. But what should you look for in a milling cutter? Understanding its features can help you pick the best one. This article will explore the best milling cutters for brass and copper, guiding you in your crafting adventures.

Best Milling Cutter For Brass And Copper: Top Choices!

Milling Cutter for Brass and Copper

Choosing the right milling cutter for brass and copper is essential for effective machining. These materials are softer and require specific tools to prevent damage and ensure clean cuts. High-speed steel and carbide cutters work best. Have you ever wondered how precision impacts quality? Even a tiny flaw can affect performance. Understanding cutter geometry can make your work smoother. With the right milling cutter, you can achieve better results and save time in your projects.Understanding Milling Cutters

Definition and purpose of milling cutters. Various types of milling cutters.Milling cutters are special tools used to cut and shape materials. They come in different types, each designed for specific jobs. For example, some are great at cutting soft metals like brass and copper, making them a favorite among engineers. Here’s a quick look at the types:

| Type of Milling Cutter | Best For |

|---|---|

| End Mill | General purpose cutting |

| Ball Nose Cutter | Curved surfaces |

| Face Mill | Flat surfaces |

Choosing the right milling cutter can make your work easier. Remember, using a cutter that suits your material is like wearing the right shoes for a race—comfy and speedy!

Characteristics of Brass and Copper

Properties that affect machining. Challenges faced when using milling cutters on these materials.Brass and copper have unique properties that make machining interesting. Both materials are soft and malleable. They can easily bend and shape, which sounds fun until you try cutting them! With milling cutters, these materials can create *gorgeous* parts, but they can also create some headaches. For instance, brass tends to chip, while copper can stick to the cutter, leading to *messy* results. Here’s a quick look at some key characteristics:

| Property | Effect on Machining |

|---|---|

| Softness | Easy to cut but may chip. |

| Malleability | Can bend but may create challenges. |

| Heat Conductivity | Can cause overheating of the cutter. |

Milling brass and copper may feel like a dance—one wrong step, and you’re in trouble! Keep your cutters sharp and your feed rates steady to avoid drama in the workshop.

Types of Milling Cutters Suitable for Brass and Copper

Highspeed steel (HSS) cutters. Carbide and cobalt cutters.When it comes to cutting brass and copper, choosing the right milling cutter can feel like a treasure hunt. High-speed steel (HSS) cutters are a favorite for their flexibility and durability. They can whizz through metal like a pro on a rollercoaster. On the other hand, carbide and cobalt cutters pack a punch. They’re super hard and resist wear, making them ideal for tougher jobs. Choose wisely, or you might end up using a spoon instead of a cutter!

| Type | Benefits |

|---|---|

| High-Speed Steel (HSS) | Flexible and durable; great for various tasks. |

| Carbide | Strong and long-lasting; perfect for hard jobs. |

| Cobalt | Extra tough; fantastic for high heat. |

Cutter Geometry and Design

Importance of cutting edge angle. Design considerations for optimal performance.The angle of the cutting edge is super important in milling. It directly affects how well the cutter works with brass and copper. A sharper angle helps in cutting smoothly, while a duller one can lead to more chips than a potato peeler at lunch! For the best results, consider the design of the cutter. Factors like tooth shape and size can make a huge difference. The right design ensures the cutter lasts longer, saving both time and money. Here’s a simple table to show how angle changes impact performance:

| Cutting Edge Angle | Performance |

|---|---|

| Sharp (30°) | Better finish, less effort |

| Flat (90°) | More chipping, rough edges |

In summary, a well-designed milling cutter can turn cutting brass and copper into an easy task. So, if you want less hassle and more fun in your workshop, pay attention to those angles!

Best Practices for Milling Brass and Copper

Recommended cutting speeds and feeds. Cooling and lubrication strategies.When milling brass and copper, cutting speeds and feeds are key. For brass, use 200-300 SFM (Surface Feet per Minute) and for copper, aim for 150-200 SFM. These speeds keep things smooth and shiny. Don’t forget about cooling! A good strategy is to use cutting oil or coolant to prevent overheating. Too hot, and your metal may melt faster than ice cream on a sunny day!

| Metal Type | Recommended SFM |

|---|---|

| Brass | 200-300 |

| Copper | 150-200 |

Lubrication is like sunscreen for your metal. It keeps the edges sharp and helps avoid nasty chips. So, keep your cutter cool and happy!

Common Mistakes to Avoid in Milling Brass and Copper

Incorrect cutter selection. Neglecting material characteristics.Choosing the wrong cutter is like trying to eat soup with a fork. It won’t help! Picking a suitable milling cutter for brass and copper is crucial. Each material needs a specific type of cutter for the best results. Ignoring how brass and copper feel and behave is a mistake too. These metals are softer and can be tricky during milling. You want them to shine, not turn into a pile of shavings!

| Common Mistakes | Advice |

|---|---|

| Incorrect Cutter Selection | Always choose cutters designed for brass and copper! |

| Neglecting Material Characteristics | Understand how your metal behaves to avoid mishaps! |

Maintenance of Milling Cutters

Tips for prolonging cutter life. Signs of wear and how to resharpen.Caring for your milling cutters is like caring for a beloved pet. Give them some love, and they will work harder for you! To extend the life of your cutters, keep them clean and stored properly. Look out for signs of wear, like chips or dullness. If your cutter looks sad, it’s time to resharpen! Frequent checks can save you money and keep your work smooth.

| Tip | Sign of Wear | Resharpening Method |

|---|---|---|

| Keep it clean | Chips on the edge | Use a grinder |

| Store properly | Dull cutting | Sharpening stone |

Remember, a happy cutter means a happy you! Treat them right, and they’ll help you cut through brass and copper like butter.

Conclusion

In summary, milling cutters designed for brass and copper make machining easier and more efficient. They help you create precise shapes and smooth finishes. Choose the right cutter for your project to achieve better results. We encourage you to explore different types and practices to enhance your metalworking skills. Reading more about these tools can boost your confidence in your next project!FAQs

What Are The Key Factors To Consider When Selecting A Milling Cutter For Machining Brass And Copper Materials?When choosing a milling cutter for brass and copper, you need to think about the material type. Use cutters made of hard metals to last longer. The shape of the cutter matters too; flat edges work well for these soft metals. You also want a cutter that can handle high speeds, since brass and copper can be milled quickly. Finally, remember to pick a cutter that helps remove chips easily while you work.

How Do Different Coatings On Milling Cutters Affect Their Performance And Longevity When Working With Brass And Copper?Different coatings on milling cutters help them last longer and work better. Some coatings can make the cutters sharper and reduce friction. This means they cut through brass and copper more easily. When you choose the right coating, your cutters won’t wear out as fast. This saves you time and money when working on projects.

What Are The Recommended Feed Rates And Cutting Speeds For Milling Copper And Brass Using High-Speed Steel Versus Carbide Cutters?When milling copper and brass, we should use different speeds and feed rates based on the cutter type. For high-speed steel cutters, a good speed is about 100 to 200 feet per minute. For carbide cutters, you can go faster, around 300 to 600 feet per minute. Also, feed rates can be about 0.003 to 0.008 inches per tooth for steel and carbide. Always remember to check the cutter’s limits for the best results!

How Can Tool Geometry Impact The Efficiency And Quality Of A Milling Process For Brass And Copper Components?Tool geometry is how the cutting tool is shaped. If you choose the right shape, it helps cut brass and copper better. A sharp tool can slice through the metal easily, making clean cuts. This means less time and effort for you. It also makes the pieces look nicer.

What Are The Common Challenges Encountered When Milling Brass And Copper, And What Milling Cutter Designs Can Help Mitigate These Issues?When we mill brass and copper, we face a few problems. These metals can get very hot and stick to the tools. They can also break or chip easily. To help, we can use special cutters with sharp edges and certain shapes. These designs can cut better and keep the metal from sticking.