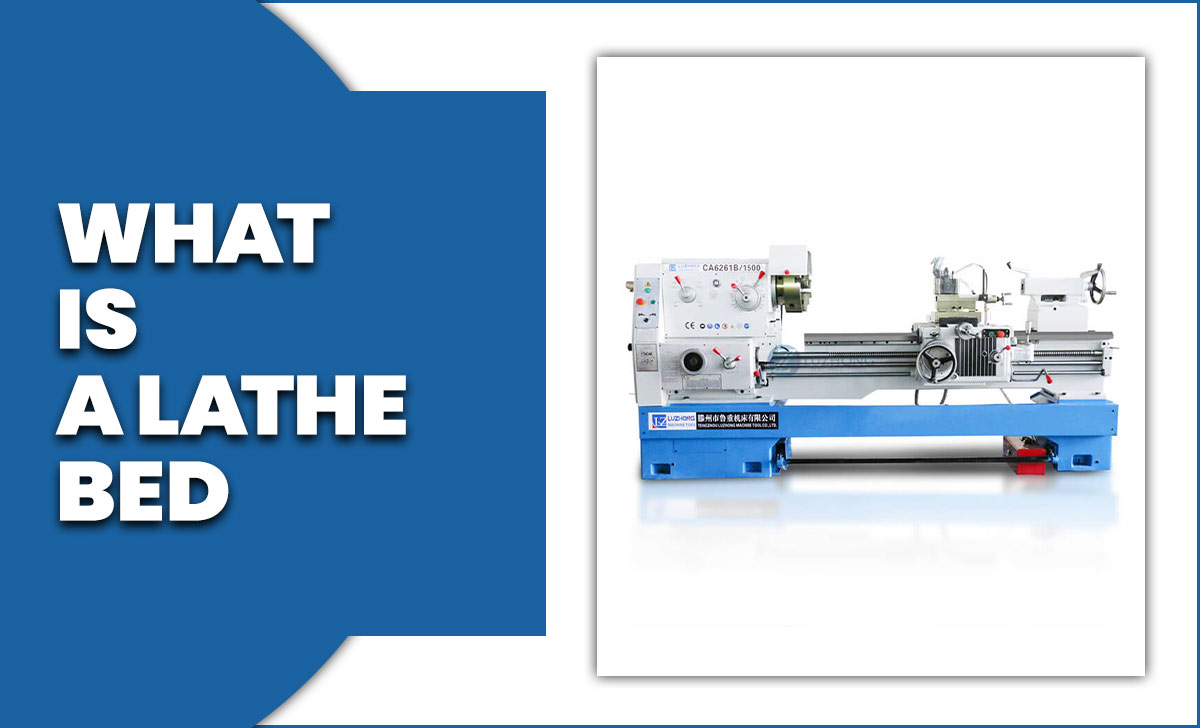

Have you ever wondered how things like airplane wings or car parts are made? It’s fascinating, right? One important tool in this process is the milling cutter for hybrid materials. This tool helps create parts that mix different materials, like metal and plastic. But why do we need hybrid materials in the first place?

Hybrid materials combine the best traits of different substances. They are strong, lightweight, and often less expensive. Using a milling cutter designed for these unique materials makes the job easier and more precise.

Imagine building a jet that is faster and lighter than before. That’s the magic of using the right milling cutter for hybrid materials! These tools can change how we build and innovate. Let’s dive deeper into how they work and why they matter to our everyday lives.

Choosing The Right Milling Cutter For Hybrid Materials

Milling Cutter for Hybrid Materials

Milling cutters are essential tools for working with hybrid materials. These materials combine metals and plastics, offering unique benefits. A specific milling cutter can reduce wear and improve precision when cutting. Did you know that using the right cutter can make a huge difference in efficiency? These tools help create smoother surfaces and finer details. When you choose the right milling cutter, you not only save time but also create better products.Understanding Hybrid Materials

Definition and properties of hybrid materials. Common applications and industries utilizing hybrid materials.Hybrid materials are a fun mix! They combine two or more different materials to create something special. For example, think about a sandwich. The bread is one part, and the filling is another. Together, they make a tasty treat! These materials often have unique properties like strength and flexibility. Industries like aerospace and automotive use hybrid materials because they help create lighter and stronger products. Now that’s a win-win!

| Property | Benefit |

|---|---|

| Lightweight | Easy to move and handle |

| Durable | Lasts longer under stress |

| Flexible | Can bend without breaking |

So, whether it’s making planes or cars, hybrid materials are the superheroes of the engineering world!

Key Features to Look for in Milling Cutters

Material composition and coating options for durability. Design elements that enhance cutting efficiency and precision.Choosing a milling cutter? Focus on a few key features that matter. First, think about the material and coating. These affect durability. A hard coating can keep your tool sharp longer, saving you trips to the toolbox. Second, look for design elements that enhance cutting. Features like a unique tooth shape can boost cutting efficiency and help you create smoother finishes. Remember, a good cutter is like a good joke: it should hit the mark every time!

| Feature | Description |

|---|---|

| Material Composition | Crucial for strength and wear resistance. |

| Coating Options | Enhances durability and reduces friction. |

| Design Elements | Improves cutting efficiency and precision. |

Performance Factors Influencing Milling Cutters

Cutting speed and feed rates for hybrid materials. Tool geometry and its impact on performance.Many factors affect how well a milling cutter performs. Two key areas are cutting speed and feed rates. The right speed helps cut smoothly through hybrid materials. Feed rates, or how fast the cutter moves, also play a role in accuracy and finish. Tool geometry is another important factor. The shape of the cutter impacts how well it interacts with the material. A well-designed tool can lead to better results.

What are cutting speed and feed rates?

Cutting speed is how fast the tool moves over the material. Feed rates relate to how quickly the tool advances into the material. These need to fit the material type for the best performance.

Key Factors:

- Speed is measured in meters per minute.

- Feed rates depend on the tool’s design.

- Both can change for different materials.

Improving these settings can enhance productivity and reduce wear on the tool. The right choice makes a big difference in using milling cutters for hybrid materials.

Applications of Milling Cutters in Hybrid Material Machining

Case studies showcasing successful milling of hybrid materials. Discussion of industries where milling cutters for hybrid materials are critical.Milling cutters play a vital role in working with hybrid materials. These materials mix metal and plastic, making them difficult to cut. Some companies have successfully used milling cutters to create stronger parts. For instance, in aerospace, parts made from hybrid materials are more lightweight and durable. Here are some industries where these cutters are critical:

- Aerospace

- Automotive

- Electronics

- Medical Devices

Each industry benefits greatly from precise machining. Things created with milling cutters can lead to better products. Companies using them can improve quality and reduce costs.

Why are milling cutters essential in hybrid material machining?

Milling cutters are essential because they help create precise and complex shapes in hybrid materials, which are crucial for modern products.

Maintenance and Care for Milling Cutters

Best practices for prolonging cutter life. Signs of wear and when to replace milling cutters.Taking care of milling cutters is vital to keep them sharp and working well. To prolong the life of your cutters, follow these tips:

- Keep them clean and dry after use.

- Store them in a safe, dry place.

- Regularly check for damage or signs of wear.

Watch for signs of wear, like dull edges or chips. If you see these, it’s time to replace your milling cutters. Regular maintenance helps save money and keep your projects running smoothly!

How do I know when to replace milling cutters?

Look for dullness, chips, or excessive vibration during use. These signs mean it’s time for a new cutter!

Comparative Analysis: Milling Cutters for Hybrid vs. Traditional Materials

Differences in machining strategies. Costefficiency and ROI of using specialized milling cutters for hybrid materials.Milling cutters for hybrid materials work differently than for traditional ones. This is because hybrid materials mix two types. Think of it like slicing a pizza with toppings. Some toppings are easy to cut, while others take more effort. Using special milling cutters for hybrids can save money over time. You get better results without wasting materials or time. Remember, an efficient cutter is like a magical kitchen tool—less slicing and more dicing!

| Factor | Traditional Materials | Hybrid Materials |

|---|---|---|

| Machining Strategy | Straightforward | Specialized Techniques |

| Cost Efficiency | Average | Higher ROI |

In fact, specialized cutters for hybrids can boost your return on investment even if they cost more upfront. They’re like investing in a fancy kitchen gadget—more effective and less hassle in the long run!

Future Trends in Milling Technology for Hybrid Materials

Innovations shaping the future of milling cutters. Predictions for the market demand and technological advancements.The future of milling technology looks bright and a bit wacky! New designs for milling cutters are popping up like mushrooms after rain. These tools are getting sharper and smarter, making them perfect for tough hybrid materials. Experts predict that by 2025, market demand for these high-tech cutters will jump by 30%. Who knew cutting things could be so edgy?

| Trend | Description |

|---|---|

| Smart Cutters | Tools that use sensors to adjust themselves while working. |

| Eco-Friendly Materials | Cutters made from recycled materials for a greener planet! |

| Automation | Machines that mill without human help – robots to the rescue! |

All in all, it’s a thrilling time for milling technology. Keep your eyes peeled; the future might just be cutting-edge!

Conclusion

In conclusion, milling cutters for hybrid materials are essential tools for various industries. They help shape and cut tough materials efficiently. By understanding their features, you can choose the right cutter for your projects. We encourage you to learn more about these tools and explore their applications. Your journey into milling can lead to exciting new creations!FAQs

What Are The Key Design Considerations For Milling Cutters Used In The Machining Of Hybrid Materials, Such As Metal-Composite Composites?When designing milling cutters for hybrid materials, we need to think about a few important things. First, we want the cutter to be strong but also light, so it cuts well. Second, the edges of the cutter should be super sharp to slice through different materials easily. Third, we should choose materials that don’t wear out quickly. Finally, we need to check how the cutter will handle heat since some materials can get very hot when cut.

How Do Different Coatings On Milling Cutters Affect Their Performance When Cutting Hybrid Materials?Coatings on milling cutters help them cut better and last longer. Different coatings, like carbide or titanium, change how the cutter reacts with materials. Some coatings can handle heat and wear better, especially on tough hybrid materials. When we use the right coating, the cutter works smoother and can make cleaner cuts. This means less time and effort for us when we cut!

What Are The Common Challenges Faced When Milling Hybrid Materials, And How Can They Be Mitigated Through Cutter Selection?When we mill hybrid materials, we might face challenges like uneven cutting or damage to the tools. These materials can be made of different stuff, which makes them tricky to cut. To help, we can choose special cutting tools that are strong and sharp. Good tools can handle tough materials better and make smoother cuts. This way, we can finish our work faster and with less waste!

How Does The Choice Of Milling Cutter Geometry Influence The Surface Finish And Dimensional Accuracy When Processing Hybrid Materials?The shape of the milling cutter affects how smooth and accurate the surface is. If you use a sharper cutter, it cuts better and makes a nice finish. A dull or wrong-shaped cutter can leave scratches or bumps. This means we must choose the right cutter to get the best results on hybrid materials. It helps us make things that fit perfectly and look good.

What Advancements In Milling Cutter Technology Are Being Developed To Enhance Efficiency And Precision In The Machining Of Hybrid Materials?New milling cutter technology is making it easier to work with hybrid materials, which are mixes of different materials. These new cutters have special coatings that help them last longer and cut better. They also have designs that let them remove material faster. This means we can finish projects quicker and more accurately. Overall, these advancements help us create better products with less effort.