Have you ever wondered how manufacturers create parts from magnesium materials? This task often requires special tools. One key tool is the milling cutter. It’s like a magic wand for cutting shapes and features into metals.

Using a milling cutter for magnesium is quite interesting. Magnesium is a lightweight metal commonly used in various applications. But it can be tricky to work with. That’s why choosing the right milling cutter is so important.

Imagine carving a sculpture from clay. You need the right tools to get the details just right. The same goes for milling cutters. They help shape and refine magnesium parts with skill and precision. Did you know that magnesium can be lighter than aluminum? This makes it a popular choice in the automotive and aerospace industries.

As we explore milling cutters for magnesium materials, you’ll discover why they are essential. Each cutter brings unique benefits, helping create products that are strong and lightweight. Ready to dive deeper?

Best Milling Cutters For Magnesium Materials: A Comprehensive Guide

Milling Cutter for Magnesium Materials

When working with magnesium, choosing the right milling cutter is crucial. These cutters offer sharp edges and durable materials designed specifically for softer metals like magnesium. Did you know magnesium is one of the lightest metals used in engineering? The right tool can make cutting smoother and more efficient. Using carbide or coated cutters helps prevent issues like wear and tear, keeping your work precise. So, what’s your choice for tackling magnesium projects?Properties of Magnesium and Its Impact on Milling

Explanation of magnesium’s material properties influencing milling processes. Discussion on the challenges posed by magnesium’s physical and mechanical properties.Magnesium is a light metal known for its special properties. It is strong but can be brittle. This means it may break under stress. These characteristics affect milling processes, making them challenging. The key impacts include:

- Low density: Magnesium is lighter, making it easier to transport.

- Brittleness: It can crack or chip during milling.

- Good strength-to-weight ratio: This helps in creating strong parts.

Magnesium’s properties create both opportunities and challenges. Understanding these helps in using the right milling cutter.

What are the challenges of milling magnesium?

The main challenges include its brittleness and the risk of ignition during cutting. Proper tools and techniques are needed to prevent these issues.

Cutting Parameters for Milling Magnesium

Recommended feed rates and cutting speeds for optimal milling. Importance of coolant and lubrication during the milling process.Choosing the right feed rates and cutting speeds is key for milling magnesium. A good speed is usually between 2000 to 4000 RPM. For feed rates, 0.005 to 0.025 inches per tooth is recommended. This helps make smooth cuts and reduces issues like chipping. Using coolants and lubricants helps cool the cutter and makes the job easier. They also prevent dust and heat from building up, which is important for safety and tool life.

Why is coolant important in milling?

Coolant helps keep the work area cool and reduces friction. This improves cutting efficiency and tool life.

Key Benefits of Using Coolants:

- Reduces heat

- Improves surface finish

- Increases tool lifespan

Tool Wear and Maintenance for Milling Magnesium

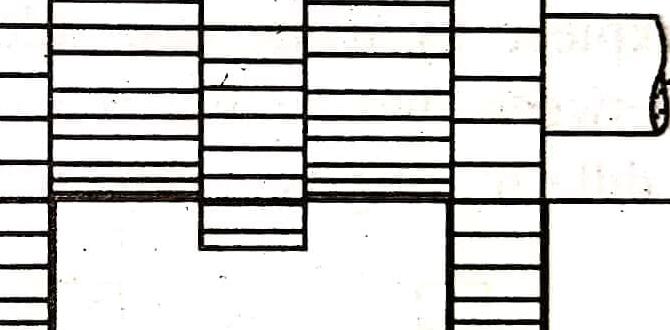

Common signs of tool wear specific to milling magnesium. Best practices for tool maintenance and replacement strategies.When milling magnesium, your tools can show signs of wear. Look for chipping, discoloration, or rough edges on the cutter. These signs mean it’s time to check your tool’s health. To keep your tools sharp, follow best practices like regular cleaning and checking for damage. Replace them before they become useless, or they might start making your work look like a Picasso painting! Here’s a handy table for quick reference:

| Tool Wear Signs | Maintenance Tips | Replacement Strategies |

|---|---|---|

| Chipping | Clean after each use | Replace tool every 50 hours |

| Discoloration | Check for heat buildup | Have a backup ready |

| Rough edges | Inspect regularly | Replace at the first sign |

Safety Considerations When Milling Magnesium

Potential fire hazards and how to mitigate them. Proper handling and disposal of magnesium shavings and debris.Milling magnesium can be tricky due to its flammability. A tiny spark might turn magnesium shavings into a fireball. To stay safe, keep your workspace tidy and use vacuum systems for cleanup. Always work in a well-ventilated area, and don’t use water to put out magnesium fires; it only makes things worse. Instead, grab a Class D fire extinguisher. Remember, a clean shop is a safe shop!

| Handling Tips | Disposal Methods |

|---|---|

| Use vacuum systems. | Store in metal containers. |

| Wear protective gear. | Recycle whenever possible. |

| Avoid water for fires. | Contact local waste authorities. |

Taking these steps can keep you and your workspace safe while milling. Remember, safety first, and leave the fireworks for the Fourth of July!

Future Trends in Milling Technology for Magnesium

Innovations in milling cutter design for enhanced performance. Advances in machining techniques for magnesium alloys and composites.New designs in milling cutters are making a big difference for magnesium. These innovative tools improve performance and efficiency. Recent advances in machining techniques help to shape magnesium alloys and composites easier. As a result, manufacturers can create lighter and stronger products.

What are some innovations in milling technology?

Innovations include special coatings for cutting tools, new shapes for better cutting, and smart technology that tracks performance.

- Better coatings reduce wear and tear.

- Unique shapes help cut smoothly.

- Smart tools provide feedback for improvements.

Future trends look bright for milling technology. Manufacturing will continue to evolve, making it faster and more efficient to work with magnesium materials.

Conclusion

In conclusion, using the right milling cutter for magnesium is vital for success. Choose high-speed steel or carbide tools for better results. Always consider the cutter’s design, as it affects efficiency and finish. Now that you know the basics, explore more resources to improve your skills. Practice using these tools, and you’ll become a pro at working with magnesium!FAQs

What Are The Key Considerations When Selecting A Milling Cutter For Machining Magnesium Materials?When picking a milling cutter for magnesium, you should think about a few important things. First, use a cutter made of strong metal. This helps it last longer. Second, select a cutter with many sharp edges. Sharp edges make cleaner cuts. Finally, consider using a special coating to reduce heat and stickiness while you work.

How Does The Choice Of Cutting Tool Geometry Affect The Machining Process Of Magnesium Alloys?The shape of the cutting tool is very important when we work with magnesium alloys. A sharp tool cuts better and makes nice, smooth edges. If the tool is too dull or has the wrong shape, it can create rough surfaces and even break. We need the right angles and sizes to be safe and work efficiently. So, choosing the right tool helps us make better parts quickly and easily.

What Cooling And Lubrication Strategies Are Recommended When Milling Magnesium To Prevent Ignition And Enhance Tool Life?When milling magnesium, you should use special cooling liquids to keep it from getting too hot. These liquids help prevent sparks, which can cause fires. Using a lot of coolant also helps the tools last longer. You want to keep the surfaces slick to reduce friction while you work. Always stay careful and watch for any signs of burning!

Are There Specific Coatings Or Materials That Are More Effective For Milling Cutters Used On Magnesium Compared To Other Metals?Yes, some coatings work better for milling cutters when cutting magnesium. For example, coatings like titanium nitride (TiN) can help cutters last longer. We also use carbide materials because they are strong and can handle heat. These choices help make cutting magnesium easier and safer.

What Are Common Challenges Faced During The Milling Of Magnesium, And How Can They Be Mitigated Through Appropriate Tool Choice And Machining Parameters?When we mill magnesium, we can face problems like dust and overheating. The dust can catch fire easily, so it’s important to use special tools that are strong enough and have the right coatings. We should also use slow cutting speeds and keep the materials cool to avoid heat. By choosing the right tools and adjusting our machine settings, we can make milling safer and easier.