Have you ever thought about how we make huge turbine blades? It’s not just magic; it’s engineering! One key tool in this process is a milling cutter for roughing turbine blades. This special cutter shapes the blades into their best form. But why is it so important?

Imagine standing next to a massive jet engine. You can see the turbine blades shining bright. They work hard to help planes fly high. But did you know that making these blades is a tough job? The milling cutter helps make it easier by removing a lot of metal quickly. This saves time and makes the blades strong.

With the right milling cutter, manufacturers can create blades that help engines run smoothly and efficiently. So, the next time you see a plane take off, remember the hard work that goes into its turbine blades!

Milling Cutter For Roughing Turbine Blades: An Essential Tool

Milling Cutter for Roughing Turbine Blades

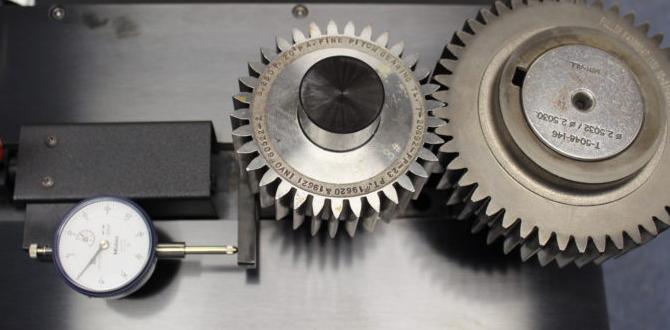

Milling cutters are essential for shaping turbine blades. They quickly remove large amounts of material and save time. Did you know that the right cutter can improve efficiency by 30%? These tools have special designs to handle tough materials. They create smooth surfaces, which help blades work better. Proper use can lead to longer-lasting blades. Choosing the right milling cutter can transform how engineers create these vital components. Wouldn’t you want to discover the best tools for your projects?Importance of Milling Cutters in Turbine Blade Manufacturing

Explanation of the role of milling cutters in achieving precision and efficiency.. Impacts of cutter design on the roughing process..Milling cutters are vital in making turbine blades. They help achieve precision and efficiency in the manufacturing process. A well-designed cutter shapes materials accurately. This improves speed and reduces waste. Blade design affects how smoothly the cutter works. Designers consider factors like size and shape for the best results.

- Sharp edges enhance cutting speed.

- Different shapes match various materials.

- Good design ensures less material loss.

This combination makes milling cutters essential for producing high-quality turbine blades.

How do milling cutters improve turbine blade production?

They enhance accuracy and speed, ensuring each blade fits perfectly.

Factors to Consider When Choosing a Milling Cutter

Key specifications such as diameter, number of flutes, and coating.. How to balance cost and quality in selecting the right cutter..Choosing the right milling cutter involves key specifications. First, consider the diameter. It affects how deep and wide you can cut. Next, look at the number of flutes. More flutes can create smoother finishes. Finally, check the coating, which helps the tool last longer.

Balancing cost and quality is essential. Sometimes, a cheaper cutter may wear out faster, costing more in the long run. Invest wisely for the best results.

What factors affect the choice of a milling cutter?

Key factors include diameter, number of flutes, and coating material.- Diameter: Size determines cutting depth.

- Flutes: More flutes offer smoother cuts.

- Coating: Protects the tool and enhances durability.

Best Practices for Using Milling Cutters in Roughing

Guidelines for optimizing cutting speeds and feeds for turbine blade materials.. Techniques to reduce tool wear and improve longevity during roughing..Using milling cutters effectively can lead to better turbine blade production. Here are some best practices:

- Optimize cutting speeds to match the material. Harder materials need slower speeds.

- Adjust feed rates for smooth cutting. Faster feed rates can result in poor finishes.

- Keep tools cool with cutting fluids to reduce heat and wear.

Follow these guidelines for improved tool life and better results during roughing. Remember, a well-maintained tool lasts longer and performs better!

How do I choose the right cutting speed and feed rate?

To choose the right cutting speed and feed rate, consider the material type and thickness. Use slow speeds for harder materials and faster feeds for softer ones. Matching these correctly helps achieve a smooth finish.

Innovations in Milling Cutter Technology

Latest advancements in milling cutter designs and materials.. Impact of technology on the efficiency and effectiveness of roughing operations..Exciting changes are happening in the world of milling cutters! New designs and materials make them stronger and faster. 🏎️ Now, cutters can handle tough jobs, like shaping turbine blades, with ease. These innovations boost efficiency, saving both time and money. Imagine finishing a job in half the time – that’s a win! With smart tech, cutting becomes precise and neat. Say goodbye to messy edges! 📏✨

| Feature | Old Cutters | New Innovations |

|---|---|---|

| Material Strength | Standard Steel | Ceramic Composites |

| Efficiency | Average | High Precision |

| Durability | Low | Long-lasting |

Case Studies: Successful Applications of Milling Cutters

Realworld examples of effective roughing using specific types of milling cutters.. Lessons learned from industry leaders in turbine blade production..Many companies have successfully used milling cutters to shape turbine blades. For example, one company produced blades at a faster rate using specialized roughing cutters. They learned that choosing the right cutter helped reduce waste material. Another leader in the industry noted that their precision improved with better tool designs. Here are key lessons from their experiences:

- Select tools based on the blade material.

- Use advanced coatings for durability.

- Regularly train employees on new techniques.

These strategies show the importance of using modern milling cutters effectively in production.

What are milling cutters used for in turbine blade production?

Milling cutters help shape and finish turbine blades. They allow for precise cuts, improving efficiency and quality in production.

Conclusion

In summary, using a milling cutter for roughing turbine blades is essential for effective machining. It helps remove material quickly and shapes blades accurately. Understanding different cutter types will improve your projects. We encourage you to explore more about milling techniques and practice using various cutters. This knowledge will make you more skilled and confident in your work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutters For Roughing Turbine Blades:Sure! Milling cutters are tools used to shape materials like metal. For roughing turbine blades, which are parts of engines, we need strong cutters that can remove a lot of material quickly. These cutters help make the blades the right shape and size. We must choose the right type of cutter for the job to keep everything safe and efficient.

Sure! Please provide the question you would like me to answer.

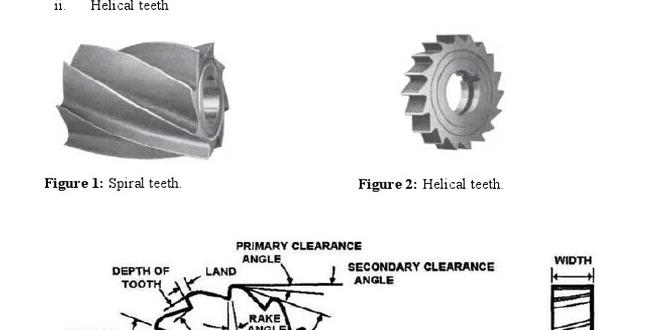

What Are The Key Design Features Of Milling Cutters Specifically Suited For Roughing Turbine Blades?Milling cutters for roughing turbine blades have special shapes and edges. They are made to cut quickly and remove a lot of material. The edges are strong to handle tough metals. These cutters also have special angles to reach tight spots on the blades. Using them helps make turbine blades faster and smoother.

How Does The Choice Of Cutting Material Influence The Performance And Longevity Of Milling Cutters Used In Turbine Blade Machining?The choice of cutting material affects how well the milling cutters work and how long they last. If we use stronger materials, the cutters can slice through tough metals better. This means they don’t wear out as quickly. Choosing the right material helps us make smooth cuts and saves money by needing fewer replacements.

What Are The Advantages Of Using High-Performance Milling Cutters Over Traditional Ones In The Roughing Process Of Turbine Blades?High-performance milling cutters are better than traditional ones for making turbine blades. They cut faster, so we finish the job more quickly. They also last longer, which means fewer tool changes. This saves us time and money. Plus, they make better shapes, so we don’t need as much extra work later.

How Do Various Milling Strategies (E.G., Climb Milling Vs. Conventional Milling) Impact The Surface Finish And Dimensional Accuracy Of Turbine Blades?Milling is like cutting shapes from a block. In climb milling, the tool moves in the same direction as the motion, which gives a smoother surface. In conventional milling, the tool cuts against the motion, which can make the surface rougher. A smoother finish means the turbine blades work better. So, using the right milling technique helps make the blades accurate and shiny.

What Role Do Coolant And Lubricants Play In The Milling Process Of Turbine Blades When Using Roughing Cutters, And How Can They Improve Machining Efficiency?Coolant and lubricants help keep the cutting tools cool and reduce friction when we shape turbine blades. This makes cutting easier and smoother, preventing damage to the blades. Using them also helps the tools last longer, which saves time and money. Overall, they help the machine work faster and more efficiently!