Have you ever wondered how metal parts get made so perfectly? One important tool for this job is the milling cutter, especially when it comes to tough materials like titanium. Using a milling cutter for titanium roughing can be pretty interesting!

Picture this: a giant machine chipping away at a piece of titanium. It sounds like magic, right? But it’s all about the right cutter and technique. Titanium is strong but also tricky to work with. That’s why choosing the right milling cutter is a big deal.

You might be surprised to learn that titanium is used in many cool things, from airplanes to sports cars. So, how does a milling cutter make all this happen? Let’s dive into the world of milling cutters and discover their secrets!

Effective Milling Cutter For Titanium Roughing Techniques

Milling Cutter for Titanium Roughing

Using a milling cutter for titanium roughing is crucial for effective machining. These specialized tools efficiently shape titanium, a metal known for its strength and lightweight properties. Did you know that titanium is often used in aerospace and medical fields? It’s true! The right cutter can enhance performance and extend tool life. Choosing sharp, durable cutters helps ensure smooth results. This knowledge is vital for anyone looking to optimize their titanium machining projects.Understanding Titanium as a Material

Properties of titanium that affect machining. Common applications of titanium in various industries.Titanium is a strong yet lightweight metal that likes to be stubborn during machining. It can make even the best tools feel like they need a vacation! This material doesn’t just have great strength-to-weight ratio; it also resists rust, making it a favorite in aerospace and medical fields. Want to know where titanium struts its stuff? Check out the handy table below.

| Industry | Common Application |

|---|---|

| Aerospace | Aircraft parts |

| Medical | Surgical implants |

| Automotive | High-performance engines |

| Marine | Sea exploration equipment |

With its unique properties, titanium is a superstar in many industries. Remember, machining titanium can be tricky, but a good milling cutter makes it much easier. Let’s buckle up and get ready to create some incredible things!

Challenges of Milling Titanium

Difficulty in chip removal during machining. Tools wear and heat generation during milling.Machining titanium brings some tough challenges. One major problem is chip removal. When cutters slice through titanium, chips can get stuck, making it hard to see and work clearly. This can slow down the process.

Another issue is tool wear and heat. Titanium is strong and can wear down cutting tools quickly. When tools get hot, they can break or lose their sharpness. This can lead to mistakes in cutting or even damage the material.

What are the main challenges of milling titanium?

The main challenges are difficult chip removal and rapid tool wear due to heat. Chip management is crucial for smooth machining, while maintaining tool durability is key to efficiency.

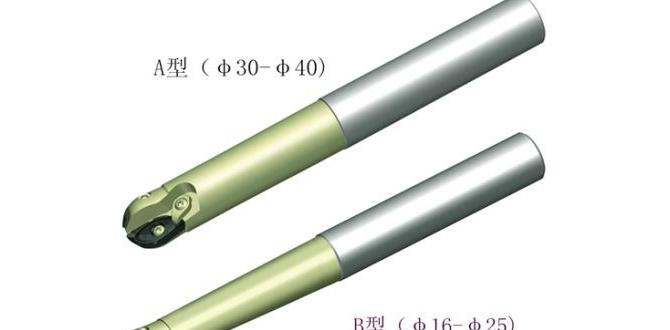

Types of Milling Cutters Suitable for Titanium Roughing

Highspeed steel (HSS) vs. carbide milling cutters. Specialized titaniumcoated milling cutters.Choosing the right milling cutter for titanium roughing is key. First up, we have High-Speed Steel (HSS) cutters. They are great for beginners because they are easier to sharpen and handle. However, they may dull faster on tough titanium. On the flip side, carbide milling cutters wear slowly and cut smoothly, making them suitable for tough jobs. Plus, specialized titanium-coated milling cutters make cutting a breeze, as they reduce friction and heat. Think of them as a superhero suit for your tools!

| Cutter Type | Benefits | Drawbacks |

|---|---|---|

| HSS Cutters | Easy to sharpen and good for general use | Dull faster on titanium |

| Carbide Cutters | Long-lasting and cuts smoothly | More expensive |

| Titanium-Coated Cutters | Reduces friction and heat | Can chip if mishandled |

Factors to Consider When Choosing a Milling Cutter

Cutter geometry and design for effective chip formation. Coating options and their impact on tool life and performance.Choosing a milling cutter is important for good results. Cutter geometry plays a big part in making chips effectively. Sharp edges help cut better and reduce heat. Also, consider the coating options. Some coatings help the cutter last longer and work well. They can prevent wear and tear. A good design and the right coating can make a big difference in performance.

What should I know about cutter geometry and coatings?

For best results, think about:

- Geometry: Different shapes cut differently.

- Coat: Protects the cutter and extends its life.

Recommended Milling Techniques for Titanium Roughing

Optimal cutting speeds and feeds. Importance of coolant and lubrication during milling.Cutting titanium can feel like trying to slice through a giant block of cheese — tricky! First, you need the right setup for those cutting speeds and feeds. Aim for a speed of around 80-120 meters per minute for optimal results. But remember, too much speed can cause melting! Next, coolant is your best friend; it keeps everything slick and cool, making sure your cutter doesn’t overheat. Plus, no one likes a sticky situation, right? Don’t forget to add lubrication to keep things running smoothly. It’s like oiling a squeaky door! Keep these tips in mind for successful titanium roughing.

| Cutting Speed (m/min) | Feed Rate (mm/rev) |

|---|---|

| 80-120 | 0.1-0.3 |

Maintenance and Care for Milling Cutters

Best practices for extending tool life. Signs of wear and when to replace milling cutters.Keeping your milling cutters in good shape is key to their long life. Regular maintenance helps them work better and last longer. Here are some best practices:

- Keep cutters clean to avoid build-up.

- Inspect them often for any signs of damage.

- Store them properly to prevent chips and dullness.

Look for these signs to know when to replace a cutter:

- Visible wear on the cutting edge.

- Unusual noises while milling.

- Poor cutting performance.

Replacing worn cutters can prevent bigger problems. A happy cutter means a happy job!

What are the signs it’s time to replace a milling cutter?

Watch for dull blades or strange sounds. Replace your milling cutter if it doesn’t cut well anymore. This helps keep your projects clean and safe!

Case Studies: Successful Titanium Roughing Applications

Examples from various industries. Lessons learned and best practices from realworld applications.Many industries use titanium for its strength and lightness. For example, the aerospace sector relies on titanium components to power planes while keeping weight down. Construction workers also use titanium to make strong supports. A big lesson learned is the importance of choosing the right milling cutter for roughing. This choice can save time, money, and headache—no one likes a machine that stalls! Here is a fun little table that shows some key industries and tips:

| Industry | Application | Best Practice |

|---|---|---|

| Aerospace | Engine parts | Use sharp cutters |

| Medical | Implants | Cool and steady |

| Automotive | Chassis | Balance speed and precision |

By following these tips, many companies have improved their titanium roughing processes. As they say, “A well-cut titanium part is a happy part!”

Future Trends in Milling Technology for Titanium

Innovations in milling cutter design. The role of automation and smart technology in titanium machining.New designs in milling cutters for titanium are changing the game. These innovations make milling faster and more efficient. Advanced materials and shapes help cut titanium better than before. Automation also plays a big role. Machines can now work on their own. Smart technology tracks every cut. With this, mistakes are fewer. This technology lets workers focus on other tasks. Together, these trends make titanium machining more precise and less costly.

What are the latest advancements in milling cutter design for titanium?

Recent advancements include improved cutter shapes and materials. These changes enhance cutting speeds and extend tool life. Better designs mean lower costs and faster production.

Key Innovations:

- New cutter shapes for better efficiency

- Stronger, lighter materials

- Automation in operating machines

- Smart technology for real-time monitoring

Conclusion

In summary, a milling cutter for titanium roughing helps you shape titanium effectively. Choosing the right cutter improves speed and efficiency. Remember to consider the cutter’s material and design for best results. If you’re curious to learn more, explore different types of milling cutters or try them out in a project. Your journey in metalworking can be exciting and rewarding!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutters For Titanium Roughing:Milling cutters are tools we use to cut metal, like titanium, into shapes. When we mill titanium, we need strong cutters because titanium is tough. The right cutter helps us make smooth and accurate shapes. We can choose different types of cutters for roughing, which means cutting away a lot of extra metal quickly. Using the right tools makes our work easier and quicker!

Sure! Please provide the specific question you want me to answer, and I’ll be happy to help.

What Are The Key Specifications To Consider When Selecting A Milling Cutter For Roughing Titanium?When choosing a milling cutter for roughing titanium, you should think about the cutter’s material, shape, and size. A strong material like carbide works best for tough titanium. The shape should help remove metal quickly, and you want a size that fits your machine. Also, consider the number of teeth on the cutter. Fewer teeth can help clear the chips better when cutting.

How Do Cutting Speeds And Feed Rates Differ When Milling Titanium Compared To Other Metals?When we mill titanium, we use slower cutting speeds and lower feed rates than with other metals. Titanium is tougher, so it needs more care. If we go too fast, we might break the tools or damage the metal. With other metals, like aluminum, we can go faster because they are softer. So, machining titanium takes more time and patience.

What Coatings Or Materials Are Recommended For Milling Cutters To Optimize Performance When Machining Titanium?To make milling cutters work better on titanium, we can use special coatings like titanium nitride or aluminum oxide. These coatings help the cutters last longer and cut smoothly. They keep the heat down and reduce sticking. Using high-speed steel or carbide for the cutter material also helps. These options work well to cut titanium nicely!

What Are The Common Challenges Faced During The Rough Milling Of Titanium, And How Can They Be Mitigated With The Right Cutter?When we rough mill titanium, it can be hard because the metal is tough and can cause cutters to chip or break. It also heats up a lot, which can make it hard to get good shapes. To fix these problems, we can use cutters made of strong materials, like carbide. These cutters stay sharper longer and handle heat better. Using the right cutter helps us make smoother parts more easily.

Can You Explain The Advantages Of Using Multi-Flute Milling Cutters Versus Two-Flute Cutters For Titanium Roughing Operations?Using multi-flute milling cutters is better for roughing titanium. These cutters have more sharp edges, so they can take away more metal at once. This means you finish your work faster. They also keep the cutter cooler, which helps it last longer. Two-flute cutters can get hot and wear out quickly.