Have you ever wondered how tiny details in manufacturing make a big difference? One such detail is the milling cutter grain orientation control. This technique helps shape metal and wood with great precision. Imagine a craftsman making a beautiful piece of furniture. The way the milling cutter works can decide if that piece turns out perfectly or not.

Many people don’t realize that the direction of the grain in a milling cutter matters a lot. It can affect how smooth the cut is. This can change everything, from the strength of the final product to how it looks. Did you know that even small changes in the grain direction can lead to surprising results? It’s true! Each piece of material has its own story, and understanding the grain helps tell that story better.

In this article, we will explore how milling cutter grain orientation control can improve your projects. We’ll dive into what it means, why it’s important, and how it can help you succeed. Are you ready to uncover the secrets of great craftsmanship?

Milling Cutter Grain Orientation Control: Enhancing Precision

Milling cutter grain orientation control helps improve the quality of cut materials. Understanding this concept ensures better durability of cutters and smoother finishes. Did you know that how grain aligns can impact performance? Proper orientation reduces wear and tear, leading to less downtime and costs. This technique can be the secret to making cutting processes easier and more efficient. So, have you considered how the grain of your cutter might affect your project?

Understanding Milling Cutters

Definition and key components of milling cutters. Types of milling cutters commonly used in the industry.

Milling cutters are tools used in machining to cut and shape materials. They have sharp edges and can create different shapes and sizes. Key parts include the body, flutes, and teeth. Some common types of milling cutters are:

- End Mills: These are used for vertical and horizontal cuts.

- Face Mills: They create flat surfaces on the workpiece.

- Slot Drills: These make narrow grooves.

- Roughing Cutters: They remove material quickly.

Choosing the right cutter improves machining and helps in milling cutter grain orientation control.

What are the main types of milling cutters?

The main types of milling cutters include end mills, face mills, slot drills, and roughing cutters. Each type serves a unique purpose in various machining tasks.

The Importance of Grain Orientation in Machining

Explanation of grain orientation and its impact on material properties. Benefits of proper grain orientation during milling processes.

Grain orientation makes a big difference when we work with materials. It affects their strength and how they break. If the grains line up correctly, the material becomes stronger and lasts longer. Proper grain orientation during milling offers great benefits, such as:

- Improved cutting performance

- Reduced tool wear

- Better surface finish

- Enhanced material strength

By paying attention to grain orientation, we can get better results in our machining tasks.

Why is grain orientation important in machining?

Grain orientation significantly impacts material strength and wear resistance. Proper orientation during machining leads to better outcomes and longer-lasting products.

Techniques for Control of Grain Orientation

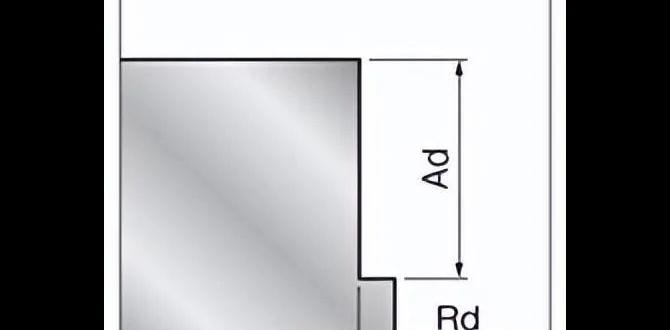

Methods for aligning grain structure in milling operations. Technology and tools available for precise grain orientation control.

In milling operations, aligning the grain structure is key for quality results. Techniques like controlled feeding and specific tool angles help twist and turn the grain just right. Newer tools, like grain-oriented milling cutters, take this control to the next level. These tools let operators adjust grain alignment with precision. Imagine chiseling your way through a giant birthday cake! The right slice depends on how you hold the knife.

| Technique | Description |

|---|---|

| Controlled Feeding | Adjust the feed rate to influence grain flow. |

| Tool Geometry | Use specific angles to align the grain effectively. |

| Monitoring Software | Employ advanced software to track and adjust grain orientation. |

Challenges in Grain Orientation Control

Common obstacles faced during milling due to grain misalignment. Potential effects of improper grain orientation on product quality.

Milling cutters face many challenges due to grain misalignment. If the grains are not lined up properly, it can lead to serious problems. Here are some common issues:

- Inconsistent cuts

- Rough surfaces

- Shorter tool life

These problems can affect product quality. For instance, improper grain orientation can create weak spots in the material. This makes the final product less durable. In some cases, it can even cause breakage during use. Keeping grains aligned is crucial for achieving the best results.

What happens with bad grain orientation?

Bad grain orientation can lead to weak products and costly mistakes. It’s vital to pay attention to the alignment to avoid these issues!

Innovations in Milling Cutter Design

Recent advancements in milling cutter technology for better grain control. Case studies showcasing successful applications of new designs.

New shapes and materials in milling cutter designs are changing the game. These innovations help in controlling grain orientation more effectively. For example, diamond-coated cutters last longer and cut better. Many companies report improved results. They often save time and money with better tools. Here are some exciting highlights:

- Special designs increase cutting precision.

- New materials resist wear and tear.

- Advanced tech simplifies the setup process.

What are the latest benefits of new milling cutter designs?

The latest designs improve efficiency, save costs, and boost production quality. They help in cutting smoother and last longer than traditional tools.

Best Practices for Milling with Grain Orientation in Mind

Recommended operational procedures for achieving optimal grain alignment. Tips for selecting the right milling cutter based on material and grain structure.

For smooth milling, keep grain orientation in focus. First, make sure your operational procedures are sharp—like your milling cutter! Align the cutter with the grain for better results. Choose the right cutter based on the material and grain structure. For soft materials, use a fine-toothed cutter; for hard ones, a more robust option is key. Remember, it’s like picking the right spoon for the soup—no one wants a spaghetti fork for that job!

| Material Type | Recommended Cutter |

|---|---|

| Soft Materials | Fine-Toothed Cutter |

| Hard Materials | Robust Cutter |

By using these tips, you’ll achieve better grain alignment and smoother cuts. Remember, happy milling means less mess!

Future Trends in Milling Cutter Grain Orientation Control

Predictions for the evolution of milling cutter technology. Potential impact of AI and automation on grain orientation control methods.

Milling cutter technology is changing fast, like a cheetah chasing its lunch! Future machines will be smarter, thanks to AI and automation. Imagine a mill that knows just where to aim for the best grain orientation. This could boost efficiency and cut costs, while making our lives easier. It’s like having a robot chef that never burns the toast!

| Trend | Impact |

|---|---|

| AI Integration | More precise grain control |

| Automation | Faster production times |

| Smart Algorithms | Optimized techniques |

As we move forward, the future looks bright for milling cutters. Who knows? Maybe one day they will even start telling jokes!

Conclusion

In conclusion, milling cutter grain orientation control is vital for improving tool performance and product quality. Understanding this concept helps you optimize your machining processes. By controlling grain orientation, you can reduce wear and increase efficiency. We encourage you to explore more about this topic and consider applying these insights in your own projects for better results!

FAQs

What Are The Primary Methods Used To Control Grain Orientation In Milling Cutters, And How Do They Impact The Performance Of The Cutting Tool?

To control grain orientation in milling cutters, we mainly use two methods: heat treatment and tool design. Heat treatment makes the material stronger by changing how the grains inside it align. Tool design helps the cutter shape and cuts better by organizing the grains in a useful way. When we use these methods, the cutting tool lasts longer and works more smoothly.

How Does The Grain Orientation Of A Milling Cutter Influence The Wear Resistance And Durability Of The Cutter During Machining Operations?

The grain orientation of a milling cutter matters a lot. When the tiny grains in the cutter are lined up correctly, it cuts better and lasts longer. This means the cutter won’t wear out as quickly during work. If the grains are not aligned well, it can break or get dull fast. So, good grain orientation helps us use the cutter more effectively!

What Role Does The Material Composition Of Milling Cutters Play In Achieving Optimal Grain Orientation Control?

The material of milling cutters affects how they cut and shape things. Strong materials help make cleaner cuts. This leads to better control of the grain in the material we are working with. When we have better grain control, our results are smoother and stronger. So, picking the right cutter material is important for good work!

How Can Advanced Manufacturing Techniques, Such As Additive Manufacturing Or Precision Machining, Be Utilized To Enhance Grain Orientation In Milling Cutters?

We can use advanced manufacturing techniques to improve how the tiny bits, or grains, are arranged in milling cutters. Additive manufacturing builds up the cutter layer by layer. This makes it easier to control the grain direction. Precision machining shapes the cutter very accurately. Both methods help create stronger and more effective tools for cutting.

What Are The Challenges And Limitations Associated With Monitoring And Controlling Grain Orientation In The Production Of Milling Cutters?

When making milling cutters, we want to make sure the tiny grains inside are lined up just right. One challenge is that it’s hard to see how the grains are arranged. We can’t just look at it with our eyes. Another problem is that even small changes in how we make the cutters can change the grain’s direction. This makes it tricky to control the quality of the cutters.