Have you ever wondered how machines cut shapes from metal? The secret often lies in the helix angle of the milling cutter. This angle plays a key role in how well the cutting tool works. Think of a milling cutter as a chef’s knife. Just like the knife’s angle affects how smoothly it slices through food, the helix angle impacts how the cutter breaks through materials.

Many people overlook this detail, but it can make all the difference. A milling cutter helix angle chart helps you find the best angle for your project. It’s like a treasure map for engineers and hobbyists. With the right angle, you can improve your work and even save time.

Did you know that different materials need different angles? For example, softer metals often work best with larger angles. Meanwhile, harder materials might require smaller ones. This surprising fact shows just how important it is to understand these angles. By using our milling cutter helix angle chart, you can become a cutting expert in no time!

Milling Cutter Helix Angle Chart: Understanding Its Importance

Milling Cutter Helix Angle Chart Summary

Understanding the milling cutter helix angle chart can truly enhance your machining skills. The helix angle affects the cutting action and chip formation. A larger angle often means smoother cuts and better chip removal. Did you know that different materials might need different helix angles for best results? This chart helps you find the right angle for various applications. Discover how small changes in angles can lead to big improvements in your work!What is Helix Angle in Milling Cutters?

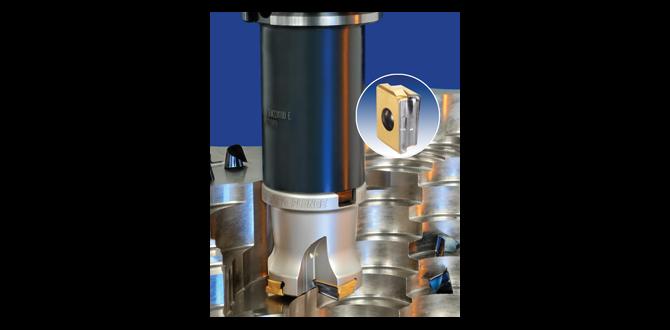

Definition and significance of helix angle. How helix angle affects cutting efficiency.The helix angle is the twist of the cutting edge on a milling cutter. It plays a big role in how well the cutter performs. A good helix angle helps make cuts smoother and faster. This leads to less wear and tear on the tool. It can also affect the type of material being cut. Understanding the helix angle helps in choosing the right cutter for different tasks.

- Improves cutting efficiency: A proper angle makes each cut easier.

- Reduces chip size: Better angles can lead to smaller chips, making cleanup easier.

- Increases tool life: Less stress on the cutter means it lasts longer.

Why is helix angle important?

The helix angle is crucial because it affects how efficiently a cutter works. A good angle allows the cutter to glide through materials smoothly and quickly. This leads to better quality cuts and longer tool life.

Typical Helix Angles in Milling Cutters

Common ranges of helix angles for various milling applications. Comparison of different angles and their uses.Milling cutter helix angles vary for different jobs. Common angles are 30°, 45°, and 60°. Each angle serves a special purpose. Here’s a look at their uses:

- 30° Helix: Best for thick materials and rough cuts. It removes more material quickly.

- 45° Helix: Great for general tasks. It balances speed and smoothness.

- 60° Helix: Ideal for fine finishes. It gives a smoother cut with less effort.

Choosing the right helix angle is key. It can make a big difference in your project’s result!

What is a milling cutter helix angle?

A milling cutter helix angle refers to the twist of the cutter’s flutes. It affects how the cutter works with the material. A proper angle improves cutting speed and quality.

How Helix Angle Influences Chip Formation

The role of helix angle in chip thickness and removal. Effects on surface finish and material flow.The helix angle of a milling cutter plays a big role in how chips form during cutting. A larger helix angle makes chips thinner and easier to remove. This helps with the smoothness of the surface finish. Also, the material flows better when the cutter has the right angle. Here’s a quick look at its effects:

- Thinner chips = easier removal

- Smoother surface finish

- Better material flow

What effects does helix angle have on chip formation?

The helix angle affects the thickness of chips. Smaller angles lead to thicker chips. This can cause more friction and heat, making cutting harder. The right angle makes the whole process smoother and helps keep the tool in good shape.

Choosing the Right Helix Angle for Material Type

Recommendations for different materials (aluminum, steel, composites). Impact of cutting speed and feed rate on helix angle selection.Choosing the right helix angle is important for different materials. For aluminum, a higher angle helps with speed and smooth cuts. For steel, a lower angle works better to reduce heat. Composite materials need a medium angle for balanced results.

Also, the cutting speed and feed rate affect the helix angle selection. Faster speeds may need steeper angles. Lower speeds do better with shallower angles.

- Aluminum: Higher helix angle (40-45 degrees)

- Steel: Lower helix angle (30-35 degrees)

- Composites: Medium helix angle (35-40 degrees)

Using the right angle can improve your work!

What is the best helix angle for aluminum?

The best helix angle for aluminum is around 40-45 degrees.How does cutting speed impact helix angle?

Higher cutting speeds often require steeper helix angles for better performance.Relationship Between Helix Angle and Tool Life

How helix angle affects wear and tear on milling cutters. Optimal angles for prolonging tool lifespan.The angle of a milling cutter can really change how long it lasts. Think of it like the best angle to attack a piñata! A sharper angle helps cut evenly and reduces wear and tear. Optimal helix angles help make the tool last longer—like finding just the right spot to swing! But remember, too steep and it may wear out faster. A balance keeps your cutter happy!

| Helix Angle (Degrees) | Tool Life |

|---|---|

| 15° | Short |

| 30° | Medium |

| 45° | Long |

Helix Angle and Machining Parameters

Analysis of how helix angle correlates with feed rates and cutting speeds. Effects of helix angle on overall machining stability.The helix angle of a milling cutter plays a big role in machining. A steeper angle can boost cutting speeds by up to 30%. This means you can finish your work faster and with better results. However, don’t get too wild! If the angle is too steep, it can cause trouble with feed rates and stability. Think of it like choosing the right angle for your big pizza slice. Get it wrong, and the toppings fly everywhere!

| Helix Angle | Feed Rate Effect | Cutting Speed Effect |

|---|---|---|

| Low Angle | Slower feed, more pressure | Lower speed, smoother cuts |

| High Angle | Faster feed, less pressure | Higher speed, potential chatter |

Overall, choosing the right helix angle can make or break your project. With the right setup, you’ll be milling like a pro!

Common Mistakes in Selecting Helix Angles

Identifying pitfalls in helix angle selection. Tips for avoiding these mistakes to enhance machining success.Selecting the right helix angle can feel like trying to pick the best ice cream flavor—so many choices! But watch out for common errors. One mistake is assuming a one-size-fits-all angle will work. Don’t be afraid to mix things up! Another pitfall is not matching the angle with your material. Always check the specifics.

To avoid mishaps, study the milling cutter helix angle chart carefully before making your choice. Testing angles on scrap materials can save headaches later. Remember, choosing wisely can make your machining smoother than a penguin on ice!

| Common Mistakes | Tips to Avoid Them |

|---|---|

| Ignoring material type | Match the angle to your specific material |

| Choosing a random angle | Refer to the milling cutter helix angle chart |

Stay sharp and happy machining!

Future Trends in Milling Cutter Design and Helix Angles

Innovations in milling cutter technology and their impact on helix angle design. Predictions for future developments in milling performance optimization.New ideas in milling cutter technology are changing how we design helix angles. Innovative materials and advanced coatings make tools last longer. Smart engineering helps improve cutting efficiency. Future trends include:

- Better precision in helix angles

- Tools that adjust to different materials

- Increased sustainability in manufacturing

These changes will help make milling faster and more cost-effective.

What is the impact of helix angle on milling performance?

The helix angle affects how the cutter bends through materials. A bigger angle helps with speed. A smaller angle provides better control. Finding the right balance is key for success.

Conclusion

In summary, a milling cutter helix angle chart helps you choose the right cutter for your job. The angle affects cutting speed and surface finish. Remember, a higher angle cuts faster, while a lower angle is better for heavy material. Explore charts online and practice choosing angles for different materials. Happy milling!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Helix Angles:Milling cutter helix angles are how the cutting edges are shaped. This shape helps the cutter move through metal or wood. A bigger angle can cut more smoothly, while a smaller angle can be stronger. Choosing the right angle depends on what you are cutting. We can make better cuts when we use the right helix angle!

Sure! Please ask your question, and I’ll provide an answer.

What Is The Significance Of The Helix Angle In Milling Cutters, And How Does It Affect The Cutting Performance?The helix angle is the tilt of the cutting edges on a milling cutter. It helps the cutter bite into the material smoothly. A good angle makes cutting easier and better, helping to make cleaner shapes. If the angle is too steep or too flat, it can cause problems, like rough cuts or a slower process. So, choosing the right helix angle is very important for good cutting performance!

How Do Different Helix Angles Influence The Chip Removal Process During Milling Operations?Helix angles change how the cutting tool slices through the material. A bigger angle makes it easier to lift the chips away. This helps keep the work area clean. If the angle is too small, chips can get stuck and cause problems. So, choosing the right angle helps things flow smoothly while we work.

What Are The Typical Helix Angles Used For Various Types Of Milling Cutters, Such As End Mills And Face Mills?Milling cutters have different helix angles, which are the twists on their cutting edges. For end mills, the helix angle is usually around 30 to 45 degrees. Face mills often have a smaller angle, like 0 to 15 degrees. These angles help the tools cut materials smoothly and easily!

How Can The Selection Of Helix Angle Impact Tool Life And Surface Finish In Machining Applications?Choosing the right helix angle affects how long a tool lasts and how smooth the part turns out. If the angle is too steep, the tool can wear out quickly. A better angle helps the tool cut more easily, making it last longer. It also creates a nicer surface that feels smooth. So, picking the right angle is very important!

In What Situations Would You Choose A Higher Versus A Lower Helix Angle For A Milling Cutter?You would choose a higher helix angle for cutting softer materials like aluminum or plastic. It helps the cutter grab the material better. A lower helix angle is better for harder materials like steel. It gives more strength and control when cutting. Choose based on what you are cutting!