Have you ever wondered how tools in machine shops get their special codes? These codes tell us a lot about the tools we use. One such tool is the milling cutter. Understanding milling cutter ISO tool coding can seem complicated, but it doesn’t have to be!

Imagine walking into a shop filled with buzzing machines and shining tools. Each milling cutter has a name, a code that describes its shape and size. This coding helps workers choose the right tool for their jobs. Without it, selecting the correct tool would be like finding a needle in a haystack!

In this article, we will explore an exciting example of milling cutter ISO tool coding. You’ll see how these codes work and why they matter. Get ready to become a little expert in the world of milling cutters!

Milling Cutter Iso Tool Coding Example Explained Clearly

Milling Cutter ISO Tool Coding Example

Milling cutters are essential tools in machining. They shape and cut materials to precise specifications. The ISO coding system helps users identify these tools easily. For example, a typical code might include letters and numbers that describe the tool’s size, shape, and material. Understanding this coding can optimize tool selection and enhance production efficiency. Did you know that the right milling cutter can significantly reduce work time? Selecting the correct tool is a game changer in manufacturing!Milling Cutter Types and Their ISO Codes

Different types of milling cutters (e.g., end mills, face mills). Examples of ISO codes for various milling cutter types.Milling cutters are crucial tools in machining. They help shape metal and wood in different ways. Here are some common types:

- End Mills: These cut at the tip and sides. They are great for various tasks.

- Face Mills: These have teeth on the face. They provide a smooth finish on surfaces.

Each type has its own ISO codes. For example:

- End Mill ISO Code: ISO 6462-2

- Face Mill ISO Code: ISO 3858

What Are Different ISO Codes for Milling Cutters?

ISO codes define cutter types clearly. Knowing them helps choose the right tool for the job. Different tools have unique codes. For example, a slotting cutter has the ISO code ISO 6172. This makes it easy to find what you need!

Interpreting ISO Codes for Milling Cutters

Breakdown of components within an ISO code. Importance of dimensions and specifications in coding.Understanding ISO codes for milling cutters can be fun! Each code has different parts, like a secret code. These components tell us important things like size and shape.

- Dimensions: Knowing the right measurements helps in choosing the correct cutter.

- Specifications: Details like the type of material make a difference in performance.

Just like picking the right tool for a job, decoding these elements ensures success in cutting tasks. Let’s explore these components together!

What are the key parts of ISO codes?

The main parts are dimensions and specifications, which tell us how to use the milling cutter best.

Why are dimensions important?

- They ensure the cutter fits correctly.

- They affect how well the cutter performs.

Practical Examples of ISO Tool Coding

Common ISO tool code examples for milling cutters. Realworld applications of these ISO codes in machining.Milling cutters use ISO tool codes to tell machines how to work. These codes are very important in making precise parts. Here are some common ISO codes you might see:

- G00: Rapid movement to the start point.

- G01: Linear cutting movement.

- G02: Circular movement clockwise.

- G03: Circular movement counterclockwise.

Real-world examples show how these codes help. They allow machines to cut metal, wood, or plastic quickly and smartly. Each code makes the cutting process smoother and more accurate.

How are ISO tool codes used in real life?

ISO tool codes guide machines in making different parts, ensuring they fit perfectly. This coding system helps factories produce everything from car parts to tiny electronic pieces. With precise programming, products have better quality and consistency.

Benefits of Using ISO Tool Coding in Milling

Standardization and its impact on manufacturing processes. Enhancing communication among engineers and machinists.Using ISO tool coding in milling offers many benefits. It creates a standard way to describe tools, making it easier for everyone in manufacturing to understand and share information. This clear communication helps engineers and machinists work together smoothly. Standardization can lead to better quality products and faster production times. It also reduces mistakes and confusion.

- Improved Understanding: Everyone speaks the same language.

- Fewer Errors: Clear instructions mean fewer mistakes.

- Faster Workflow: Easy sharing of tools speeds up production.

How does ISO coding improve manufacturing?

ISO coding improves manufacturing by ensuring everyone has a clear definition of tools, which enhances teamwork and productivity.Challenges and Considerations in ISO Tool Coding

Potential pitfalls when selecting milling cutters based on ISO codes. Importance of accurate interpretation for optimal machining results.Milling cutters come with codes that may sound like a secret language. Choosing the wrong one can lead to costly mistakes. Some common traps include assuming all cutters with the same code perform alike. It’s like thinking all cats are the same because they meow! Accurate interpretation of these codes is crucial. A small error can turn a smooth job into a messy one, costing time and money. Remember, in machining, it’s all about precision!

| Common Pitfalls | Consequences |

|---|---|

| Ignoring material specifications | Increased wear and tear |

| Assuming cutter compatibility | Poor quality results |

| Overlooking tool maintenance | Unplanned downtime |

Stay sharp by checking your ISO codes! Even a tiny misread can cause big problems. Think of it this way: would you wear two different shoes? Probably not! So, keep your eyes peeled for accurate selections to achieve optimal machining results.

Future Trends in Milling Cutter ISO Tool Coding

Innovations in tooling standards and technologies. Predictions for the evolution of ISO tool coding in the industry.The world of milling cutter ISO tool coding is transforming faster than a speeding train! Innovations are sprouting, making products smarter and more efficient. Upcoming changes promise easier coding and new standards that meet modern needs. Imagine using a tool that knows what you need before you even reach for it!

Predictions show that tool coding will get even more connected. Think about smart factories where machines can talk to each other. This could lead to fewer mistakes and smoother operations. It’s like having a conversation with your toaster, but way more exciting!

| Innovation | Description |

|---|---|

| Smart Tooling | Tools that adapt based on your needs. |

| Automatic Coding | Less manual input means fewer errors! |

| Interconnected Systems | Machines that chat for better teamwork. |

With these shifts, the future looks bright for milling cutters. If your tools can make your job easier, isn’t that a win-win?

Conclusion

In summary, the milling cutter ISO tool coding system helps you identify tools easily. Each code reveals important details about the cutter, like its shape and size. Understanding these codes boosts your machining skills and efficiency. We encourage you to explore more about tool codes to enhance your knowledge and improve your projects. Happy learning!FAQs

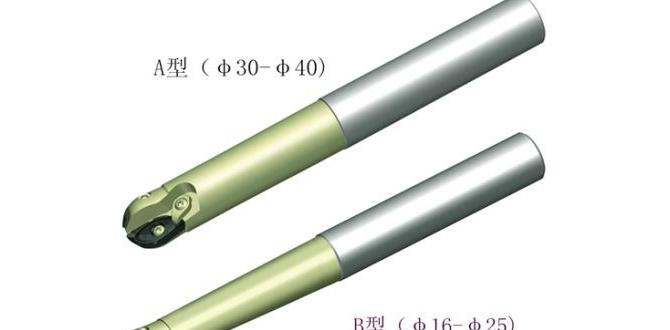

What Are The Key Components Of Iso Tool Coding Specific To Milling Cutters?ISO tool coding for milling cutters has key parts. First, we find the tool type, like a flat or ball end. Next, the diameter shows how wide the cutter is. There’s also the length, which tells us how long the tool is. Lastly, the code includes details about the material used, so we know how strong it is.

How Can You Interpret The Dimensions And Specifications Provided In An Iso Tool Code For A Milling Cutter?The ISO code for a milling cutter tells us its size and features. You can look at the numbers to know the cutter’s diameter, length, and shape. Each part of the code has a special meaning. By understanding these parts, you can choose the right cutter for your work. It helps when you want to cut different materials or shapes.

What Is The Significance Of The Different Letter Prefixes And Suffixes In Iso Tool Codes For Milling Tools?The letter prefixes and suffixes in ISO tool codes tell us important details about milling tools. For example, a prefix can show what type of tool it is, like a drill or a cutter. Suffixes can tell us the size or other special features of the tool. This information helps us choose the right tool for our tasks. Knowing these codes makes it easier for us to find and use tools correctly.

How Do Iso Tool Codes For Milling Cutters Vary From Those Used For Turning Tools Or Other Machining Tools?ISO tool codes are like special names for different tools. For milling cutters, the codes show their shape and size. But for turning tools, the codes focus more on the pointy ends used for cutting round shapes. Each type of tool has its own code system to help us pick the right one for the job. So, the main difference is what parts of the tool the codes describe.

What Are Some Common Iso Tool Code Examples For Different Types Of Milling Cutters, And How Are They Structured?ISO tool codes are like special names for tools we use when cutting with machines. Each type of milling cutter has its own code. For example, a flat-end mill might have a code like “MILL-1.” A ball nose mill could be “MILL-2.” These codes help us know what tool to use for different jobs. The codes usually start with “MILL” and then have a number to show the specific type of cutter.