Have you ever wondered how machines can shape metal so smoothly? One important tool that helps with this is the milling cutter. These cutters have a cool feature called the lead angle. But what does that really mean for you?

The lead angle affects how well the cutter can slice through materials. Imagine trying to slide a cookie cutter into dough. If you tilt it just right, it cuts perfectly. That tilt in a milling cutter can do the same thing!

Many people might not know that the way a milling cutter works can change the way we build things. From cars to toys, the lead angle can make a big difference. How can such a small angle have such a huge impact? Let’s dive deeper into the fascinating world of milling cutter lead angles and discover its hidden functions together.

Milling Cutter Lead Angle Function: Understanding Its Importance

Milling Cutter Lead Angle Function

Milling cutters can make a big difference in machining. The lead angle plays a vital role in how effectively these tools work. A good lead angle helps slice through materials more efficiently. Imagine trying to cut a loaf of bread; the sharper the angle, the easier the cut! Understanding this function can lead to better tool selection and improved machining results. Curious about how this impacts your projects? It’s worth exploring!Understanding Milling Cutters

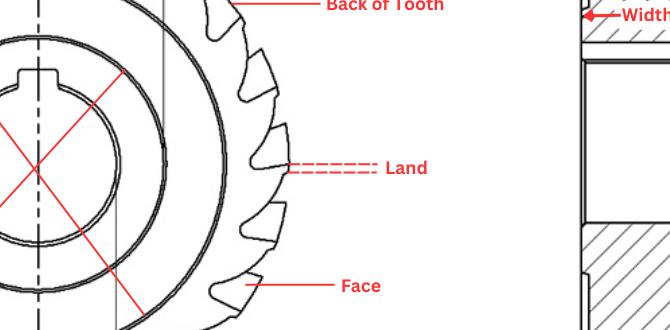

Definition and types of milling cutters. Importance in machining processes.Milling cutters are special tools used in machining to shape materials, like metal and wood. Think of them as the “cookie cutters” of the manufacturing world. There are various types, including end mills and face mills, each designed for different tasks. These tools are crucial for creating precise shapes in parts. Without them, we’d have a world full of lumpy toys and wonky furniture!Fun fact: The right milling cutter can make your projects smoother and faster, just like a hot knife through butter!

| Type of Milling Cutter | Description |

|---|---|

| End Mill | Used for cutting vertically and horizontally. |

| Face Mill | Great for cutting flat surfaces. |

| Slot Drill | Perfect for making slots and grooves. |

What is Lead Angle?

Definition and significance of lead angle in milling. How lead angle affects cutting efficiency.Lead angle is the tilt of a cutting tool when it meets the material. Think of it as the angle between the cutter and the surface you’re slicing. This angle is important because it can change how well the cutter works. A good lead angle helps the cutter slice through materials smoothly. This means less resistance and more speed! A poorly chosen angle? Well, that’s like trying to slice butter with a frozen knife—best of luck with that!

| Lead Angle | Cutting Efficiency |

|---|---|

| Small Angle | Better surface finish but slower cutting. |

| Large Angle | Faster cutting but can damage the surface. |

Choosing the right lead angle makes cutting easier and keeps the machine happy. Remember, a happy machine means more time for cake breaks!

Functions of Lead Angle in Milling Cutters

Impact on chip formation and removal. Influence on cutting forces and tool wear.The lead angle in milling cutters plays a big role in how materials are shaped and cut. First, the lead angle helps with chip formation and removal. A good angle makes it easier for chips to flow, keeping the cutting area clean. Second, it influences cutting forces and affects how the tool wears down. A proper lead angle can reduce the pressure on the cutter, which helps it last longer.

How does lead angle affect tool wear?

The lead angle helps in managing wear and tear. When angles are set right, they lessen stress on the cutter, resulting in less damage. It keeps the tool sharper for a longer time.

- Better chip removal.

- Lower cutting forces.

- Extended tool life.

Types of Lead Angles

Positive lead angles: advantages and applications. Negative lead angles: benefits and limitations.Lead angles play a big role in how milling cutters work. A positive lead angle can improve cutting efficiency and give a smooth finish. It helps slice through materials like butter. Imagine cutting your cake with a shiny knife—easy and fast! On the other hand, a negative lead angle can be tricky. It offers added strength but can create rough edges. You might say it’s like trying to cut a pizza with a spoon—it just doesn’t end well!

| Lead Angle Type | Advantages | Limitations |

|---|---|---|

| Positive | Improves cutting speed, better surface finish | May wear out faster |

| Negative | Increased tool strength | Can produce rougher surfaces |

Calculating Lead Angle for Milling Applications

Mathematical formulas for determining lead angle. Factors affecting lead angle calculations.Understanding how to calculate lead angle is like solving a jigsaw puzzle. It involves a few key formulas and some math magic. First, you need to know the lead angle formula: it’s the inverse tangent of the ratio of the cutter’s height to its radial depth. Several factors can affect this angle, like cutter geometry and material properties. Don’t worry; it’s not rocket science! Just take your time, and you’ll find that the numbers add up nicely. Here’s a quick table to help!

| Factor | Effect on Lead Angle |

|---|---|

| Cutter Diameter | Larger diameters increase lead angles. |

| Feed Rate | Higher feed rates can lower lead angles. |

| Material Hardness | Harder materials often require different lead angles. |

Knowing these will help you get the perfect cut every time. Remember, practice makes perfect – and maybe a few funny mishaps too!

Optimization of Lead Angle for Machining Efficiency

Techniques to optimize lead angle in operations. Case studies showcasing optimized milling processes.Optimizing lead angles is key for better machining efficiency. Simple techniques can lead to big improvements. Here are a few effective methods:

- Adjusting the lead angle can help reduce cutting forces.

- Select the right cutter geometry for specific materials.

- Testing different angles can reveal optimal settings.

In one study, a change in lead angle improved production speed by 30%. Such adjustments not only save time but also enhance tool life. Using the right angle is essential for any successful milling operation.

How does lead angle affect machining efficiency?

Lead angle impacts efficiency by influencing cutting forces and surface quality. A good lead angle can mean smoother cuts and longer tool life, making tasks quicker and more effective.

Common Issues Related to Lead Angle

Potential problems caused by incorrect lead angle. Solutions and best practices for troubleshooting.Incorrect lead angles can cause serious problems in milling. Cut quality suffers, leading to rough surfaces and wasted material. The tool may wear out faster, causing expensive repairs. To fix these issues:

- Check the lead angle regularly.

- Adjust the angle if the cut is poor.

- Use the right cutter for the job.

- Keep tools clean and in good shape.

These practices help you avoid problems and keep production smooth.

What problems can arise from incorrect lead angle?

Incorrect lead angles can lead to poor quality cuts, increased wear, and wasted resources. These issues can slow down your work and raise costs.

How can I troubleshoot lead angle issues?

- Regular checks on the lead angle.

- Prompt adjustments based on performance.

- Proper tool maintenance practices.

Future Trends in Milling Cutter Design

Innovations in lead angle design for improved performance. Predictions for advancements in milling technology.New designs for milling cutters focus on the lead angle to boost cutting power. These advancements promise better precision and efficiency. For example, a sharper lead angle can reduce friction, making cuts smoother. Experts predict we will see:

- More adjustable lead angles for different materials.

- Stronger materials to extend cutter life.

- Smart technology to enhance milling performance.

As technology grows, milling machines will become faster and more accurate. This change can lead to exciting opportunities in manufacturing and production.

What innovations are shaping milling cutter design?

Innovations like improved lead angles and smart technology are making milling cutters more efficient and long-lasting.

Conclusion

In summary, the milling cutter lead angle greatly impacts cutting performance. A proper lead angle helps improve chip removal and surface finish. By understanding these concepts, you can choose the right tools for your projects. Explore more about milling techniques to enhance your skills. Remember, practice makes perfect, so keep experimenting with different angles and cutters!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Lead Angle Function:Milling cutters are tools that help shape materials like metal or wood. The lead angle is the slant of the cutter’s edge. It helps the cutter slice through the material smoothly. With the right lead angle, you get cleaner cuts and better shapes. We use it to make our work easier and more precise!

Sure! Just ask your question and I’ll give you a short and simple answer.

What Is The Significance Of The Lead Angle In Milling Operations, And How Does It Influence The Cutting Performance Of Milling Cutters?The lead angle is important in milling because it helps the cutter bite into the material better. A good lead angle makes cutting smoother and faster. It can also help reduce wear on the cutter, which means it lasts longer. So, the right lead angle can make a big difference in how well we can cut shapes and parts.

How Does Altering The Lead Angle Of A Milling Cutter Affect The Surface Finish And Dimensional Accuracy Of The Workpiece?Changing the lead angle of a milling cutter can change how smooth the surface of your workpiece is. A different angle lets the cutter grab the material in a new way. If you choose the right angle, you can get a better finish and make your piece the right size. But if you pick a bad angle, it might leave marks and not fit correctly. So, it’s important to pick the best angle for your project!

What Are The Different Types Of Milling Cutter Lead Angles Used In Machining, And In What Applications Are They Typically Employed?In machining, we use different milling cutters with lead angles. A lead angle is the tilt of the cutter. There are mostly two types: positive lead angles and negative lead angles. Positive lead angles help cut smoothly and are good for shaping metal parts. Negative lead angles are better for rough cutting materials like wood or plastic. Each angle is useful for different jobs and helps us make things easier and faster!

How Does The Lead Angle Impact The Chip Formation Process During Milling, And What Role Does It Play In Tool Wear And Lifespan?The lead angle helps the cutting tool slice through the material easier. When the angle is good, chips form better and smoother. This means the tool works well and lasts longer. If the angle is wrong, the tool can wear out quickly. So, the right lead angle keeps everything running smoothly and saves tools.

What Considerations Should Be Taken Into Account When Selecting The Appropriate Lead Angle For A Specific Milling Operation Or Material?When you choose a lead angle for milling, think about the material you’re cutting. Softer materials might need a bigger lead angle. A smaller lead angle can work better for harder materials. You should also consider the tool shape and how it will affect the cut. It’s important to match the angle to get the best results!