Have you ever wondered how machines create perfect shapes from solid metal? One key player in this process is the milling cutter. These cutters are essential for shaping materials, but they need the right kind of help to work best. That’s where milling cutter lubrication flow modeling comes in.

Imagine trying to ride a bike without oil in the gears. It would be slow and hard, right? The same idea applies to milling cutters! They rely on proper lubrication to cut smoothly. But how do we know just how much lubricant to use?

Using models to understand lubrication flow can make a big difference. It helps engineers design better machines and save time and resources. This topic is not just fascinating; it is vital for improving manufacturing. Join us as we explore how modeling can improve the flow of lubricant for milling cutters, making our machines work better and longer!

Milling Cutter Lubrication Flow Modeling: An In-Depth Guide

Milling Cutter Lubrication Flow Modeling

Milling cutter lubrication flow modeling is crucial for better machine performance. Proper lubrication helps reduce friction, which leads to longer tool life. Imagine cutting materials without overheating tools—that’s what effective lubrication aims for. By modeling how fluids move, engineers can identify the best ways to deliver lubricant. This process minimizes wear and tear, saving time and costs. Plus, it enhances precision in machining processes, making it essential for efficient manufacturing. Isn’t it fascinating how a little oil can make a big difference?Understanding the Importance of Lubrication in Milling

The role of lubrication in reducing wear and tear on milling cutters. Impact of lubrication on machining efficiency and surface finish.Lubrication is like a superhero for milling cutters. It saves the day by keeping them from wearing out too quickly. Without it, the cutters can face a rough life, much like a cat without its nap time! Good lubrication also boosts machining efficiency and improves surface finish. When the cutters slide smoothly, the results are cleaner and shinier. Can you say “machine magic”? Here’s a quick look:

| Benefit | Impact |

|---|---|

| Reduced Wear | Lasts longer, saves money! |

| Better Efficiency | Finishes tasks faster. |

| Smoother Finish | Looks sharp and shiny! |

Key Parameters Influencing Lubrication Flow Models

Factors affecting lubrication flow rates: viscosity, temperature, and pressure. Influence of cutter geometry on lubrication performance.Several key factors affect lubrication flow rates. Viscosity measures how thick a fluid is. Thicker fluids flow slowly, while thinner ones move quickly. Temperature impacts viscosity; higher heat makes liquids flow easier. Pressure also plays a role; more pressure can push the fluid through faster. Additionally, the shape of the cutter, or cutter geometry, affects how well lubrication works. A well-designed cutter helps the fluid reach important areas better.

What affects lubrication flow rates in milling?

Lubrication flow rates in milling are affected by viscosity, temperature, pressure, and cutter geometry.Factors to Consider:

- Viscosity: Thicker fluids flow slower.

- Temperature: Heat reduces viscosity.

- Pressure: Higher pressure increases flow rates.

- Cutter Geometry: Affects fluid movement efficiency.

Experimental Techniques for Measuring Lubrication Flow

Methods for assessing lubrication flow rates and patterns during milling. Importance of empirical data in validating flow models.Understanding how lubrication flows during milling is like solving a mystery. Various experimental techniques help us crack this case. Common methods include using flow meters and pressure gauges. These tools measure how fast and where the lubricant spreads. Empirical data is crucial. Why? It helps confirm if our models are right. Imagine testing a theory about cookie baking—if you never taste, can you be sure they’re good? Similarly, we need real data to verify our flow models. Check the table below for a quick overview of these methods:

| Method | Description |

|---|---|

| Flow Meters | Measures the speed of the lubricant flow. |

| Pressure Gauges | Assesses the pressure of the lubricant in different parts. |

| Laser Scanning | Captures real-time flow patterns with precision. |

Case Studies: Successful Applications of Lubrication Flow Modeling

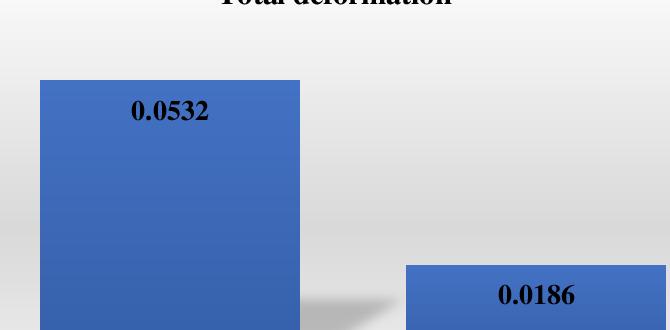

Examples of industries that have benefited from advanced lubrication modeling. Analysis of specific cases where modeling improved productivity and tool life.Many industries now use advanced lubrication flow modeling to boost their efficiency. Here are some examples:

- Aerospace: Improved tool life by 25% with better cooling systems.

- Automotive: Reduced downtime by 30% through optimal lubrication patterns.

- Manufacturing: Increased production speed, maximizing output by 20%.

Specific cases show how modeling can boost productivity and tool durability. Using proper lubrication leads to less wear on tools. This keeps machines running smoothly and lowers costs.

What industries benefit from lubrication flow modeling?

Aerospace, automotive, and manufacturing industries use lubrication models to enhance efficiency. These models help reduce waste and improve tools, resulting in better overall performance.

Future Trends in Milling Cutter Lubrication Research

Innovations in lubrication technology and modeling techniques. The potential impact of AI and machine learning on lubrication flow modeling.Researchers are excited about new ideas in lubrication technology. Recent innovations focus on how to make heat and friction control better. By improving modeling techniques, scientists can predict how well a lubricant flows. This can lead to better tools and longer-lasting machinery.

Also, artificial intelligence (AI) and machine learning are set to change the way we model lubrication flow. These smart technologies can analyze data fast. They help us find the best lubrication methods for different machines. Imagine a future where machines can suggest the best lubricant for their needs!

How will AI change lubrication modeling?

AI can help find better lubrication solutions quickly. By analyzing past data, it learns and improves over time, making lubrication smarter.

Best Practices for Implementing Effective Lubrication Strategies

Guidelines for selecting and maintaining lubrication systems in milling operations. Tips for optimizing lubrication flow based on modeling insights.Choosing the right lubrication system for milling is crucial. First, ensure it matches your machine’s needs. Poor selection can lead to clogs, and nobody wants a grouchy mill. Regular maintenance is key too. Check for leaks and clean filters often. You can optimize lubrication flow by using modeling insights. Simulate different options to find the best match. And remember, a happy machine runs smoother! Here’s a quick guide:

| Guideline | Tips |

|---|---|

| Select the Right System | Match it to your machine’s specs and demands. |

| Regular Maintenance | Check for leaks and replace filters frequently. |

| Optimize Flow | Use modeling to find the best lubrication pattern. |

Conclusion

In summary, milling cutter lubrication flow modeling helps improve machine performance. It shows how lubricant moves, reducing wear and tear. Understanding this can save you time and money in manufacturing. If you want smoother processes, explore more about lubrication techniques. You can boost your skills and knowledge, making you a better engineer or technician. Keep learning and experimenting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Lubrication Flow Modeling:Milling cutter lubrication is important because it helps machines cut better and last longer. We can model the flow of the lubricant to see how it spreads. This helps us understand how much lubricant to use and where it needs to go. By studying the flow, we can make the cutting process smoother. It’s like making sure your bike chain has enough oil to run well!

Sure! Please provide the question you would like me to answer.

What Are The Key Factors Influencing The Effectiveness Of Lubrication Flow In Milling Operations?Lubrication flow in milling operations works better when a few key things are right. First, the right amount of liquid helps reduce friction. Second, the temperature of the machine can change how well the oil moves. Third, we need to make sure the oil gets to all parts of the machine evenly. Finally, the type of oil we use matters a lot, too!

How Can Computational Fluid Dynamics (Cfd) Be Utilized To Optimize Lubrication Flow In Milling Cutter Applications?We can use computational fluid dynamics (CFD) to help improve lubrication in milling cutters. CFD lets us see how the fluid moves and flows. By studying this movement, we can find the best way to apply the lubricant. This helps keep the cutter cool and working well. In the end, better lubrication makes cutting easier and lasts longer.

What Are The Common Types Of Lubrication Systems Used In Milling, And How Do They Differ In Terms Of Flow Modeling?In milling, we use different lubrication systems to help machines run smoothly. Common types include drip lubrication, spray lubrication, and mist lubrication. Drip lubrication puts oil directly where it’s needed. Spray lubrication spreads oil as a fine mist. These systems differ in flow modeling. Drip is steady, spray is quick, and mist covers a larger area. Each has its own way of keeping things working well!

How Does The Geometry Of The Milling Cutter Affect The Distribution And Efficiency Of Lubricant Flow During Machining?The shape of the milling cutter is really important. It helps the lubricant, or oil, flow easily onto the cutting area. If the cutter has sharp edges and a good design, the oil spreads better. This helps keep everything cool and running smoothly. So, a well-shaped cutter means better lubrication and less wear on the tool.

What Are The Latest Advancements In Adaptive Lubrication Techniques For Milling Cutters, And How Do They Improve Cutting Performance And Tool Life?Recently, we have new ways to apply lubrication for milling cutters, which are tools used to cut metal. These advancements let us adjust the amount of oil or liquid oil based on the needs of the tool. This helps keep the tool cool and clean while working, making it last longer. With better lubrication, we enjoy smoother cutting and fewer broken tools. Overall, these techniques help us do our work better and save money.