Have you ever wondered why some machining tools last longer than others? The secret often lies in proper care and maintenance. For those who use milling cutters, understanding how to keep them in top shape is essential. A simple yet effective milling cutter maintenance checklist can make a big difference.

Imagine you’re at work, and your milling cutter starts acting up. It could lead to delays and more expenses. But what if you had a checklist to guide you? You can catch problems early and keep your tools sharp. Seriously, a well-maintained milling cutter can make your work smoother and quicker.

In this article, we’ll explore a useful milling cutter maintenance checklist. We’ll provide practical tips that anyone can follow. Whether you’re new to milling or a seasoned pro, this checklist can help you save time and money. Let’s dive in and make sure your milling cutters are always ready to perform!

Essential Milling Cutter Maintenance Checklist For Longevity

Milling Cutter Maintenance Checklist

Keeping your milling cutter in top shape is crucial for smooth machining. A maintenance checklist can help. Key points include regular inspection, proper cleaning, and sharpening blades to extend tool life. Did you know that a dull cutter can waste time and materials? Regular checks help catch problems early, saving you money. Following a simple routine ensures safety and efficiency. With proper care, your milling cutter can serve you well for years.Understanding Milling Cutters

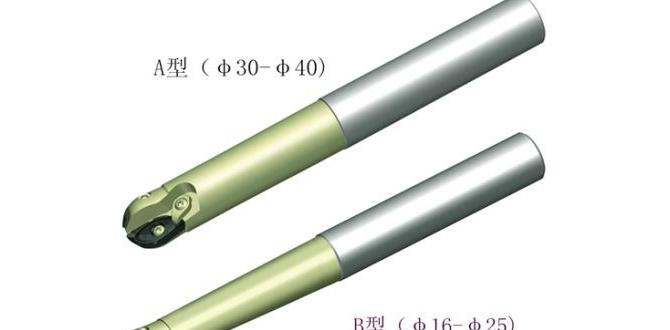

Types of milling cutters and their uses. Importance of proper maintenance for performance.Milling cutters are tools used in machining to shape and cut materials. Different types suit various tasks. Here are some common types:

- End Mill: For making deep cuts and creating flat surfaces.

- Face Mill: Perfect for large flat areas and finishing surfaces.

- Slab Mill: Great for thick materials and heavy cuts.

- Ball Nose Mill: Ideal for curved surfaces and details.

Proper maintenance keeps these tools sharp and effective. It ensures smooth operation and longer tool life. A well-maintained cutter can perform up to 30% better. Regular checks can save time and money in the long run.

What are the main types of milling cutters?

Some main types include end mills, face mills, slab mills, and ball nose mills.Why is maintenance important for milling cutters?

Maintenance is important because it improves performance and extends tool life.Daily Maintenance Practices

Cleaning procedures after each use. Inspecting for visible wear and damage.After every use, keeping your milling cutter clean is important. Dirt and debris can harm your tools and affect their performance. Follow these steps for daily care:

- Wipe the cutter with a soft cloth.

- Remove chips and dust from its surface.

- Use a brush for hard-to-reach areas.

Also, check your cutter for any visible wear or damage. Look closely at the teeth and edges. Catching issues early can save time and money!

How often should I check my milling cutter?

Inspect your milling cutter daily after each use. Catching problems early can prevent costly repairs and downtime!

Weekly Maintenance Checklist

Lubrication of cutting edges and bearings. Checking alignment and balance of the milling cutter.Every week, keep your milling cutter in top shape. Start by lubricating the cutting edges and bearings. A little oil can go a long way in keeping parts moving smoothly. Next, check if the cutter is aligned and balanced. Proper alignment helps prevent damage and ensures a clean cut. Use this quick checklist to guide you:

- Oil the cutting edges

- Grease the bearings

- Inspect for any wear

- Check alignment with a ruler

- Balance the cutter if needed

Why is lubrication important?

Lubrication reduces friction and helps tools last longer. It also prevents rust and wear, which can save money on repairs.

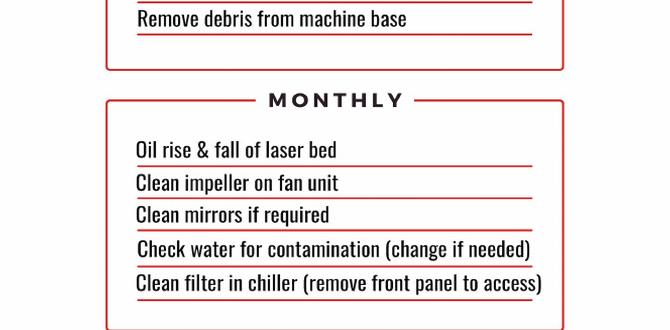

Monthly Maintenance Guidelines

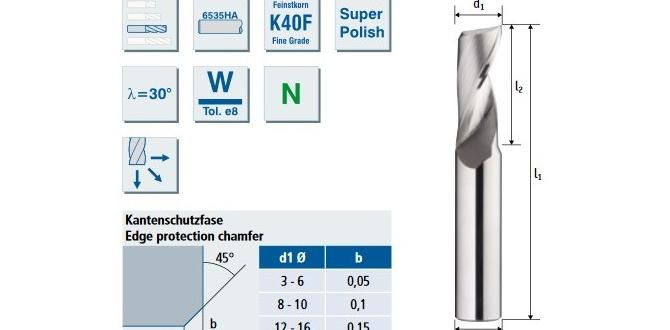

Comprehensive inspection for wear and tear. Sharpening techniques to maintain cutting efficiency.Monthly upkeep for milling cutters is vital. It helps catch wear and tear early. Check for dull edges or chips. Replace any damaged cutters. Sharpening is key for smooth operations. Use proper sharpening tools. A sharp cutter reduces machine strain and keeps cuts clean. Here’s how to maintain your cutter:

- Inspect for visible damage.

- Clean after each use.

- Use sharpener regularly.

- Follow sharping angle guidelines.

How can you tell if a milling cutter needs sharpening?

Look for rough cuts or signs of wear. If the cutter isn’t making smooth, clean edges, it’s time to sharpen. Regular checks ensure high performance and safety.

Common Signs of Worn Milling Cutters

Identifying performance drops. Symptoms indicating the need for replacement.Worn milling cutters often show clear signs before they completely give up. First, if you notice a decline in cutting speed, it might be time to check your tools. A usual sign is a rough surface finish on cut pieces. If your cutter struggles to hold proper dimensions or leaves burrs, it’s waving a little white flag. And if your machine starts making weird noises, it’s basically yelling for help! It’s wise to replace them before they cause more trouble.

| Sign of Wear | Action |

|---|---|

| Decline in cutting speed | Inspect cutters |

| Rough surface finish | Consider replacement |

| Weird noises | Immediate check |

Storage Recommendations

Proper storage methods to prevent damage. Environmental factors to consider for longevity.Storing milling cutters properly is vital. Keep them in a dry place, away from moisture. Humidity can cause rust, ruining the tools. You should use protective cases or cabinets. This shields them from dust and impacts. Also, avoid extreme temperatures. Heat and cold can damage the material.

Follow these tips to ensure longevity:

- Keep cutters in a cool, dry area.

- Use protective cases.

- Avoid exposure to moisture and direct sunlight.

Why is proper storage important?

Proper storage extends the life of your cutters. It prevents rust and keeps them sharp. This saves money on replacements and repairs.

Safety Considerations in Milling Cutter Maintenance

Personal protective equipment (PPE) requirements. Safe handling practices during maintenance activities.Keeping safe during milling cutter maintenance is super important! First, you need the right gear. Wear gloves, goggles, and a mask to protect yourself. Imagine looking like a superhero while fixing your tools! Next, handle your cutters gently. They can be sharp and sneaky. Always hold them by the right spot and ensure your workspace is tidy. Clutter can lead to playful accidents, and we don’t want any surprise stabs from rogue tools!

| Personal Protective Equipment (PPE) | Purpose |

|---|---|

| Gloves | Protect hands from cuts |

| Goggles | Shield eyes from debris |

| Mask | Prevent inhaling dust |

Tools and Products for Effective Maintenance

Recommended cleaning and lubricating agents. Essential tools for maintenance and inspection.Keeping milling cutters in great shape needs the right tools and products. First, you should use special cleaners. They remove dirt and grease easily. For lubrication, choose oils that protect against rust. Here are some key items you’ll need:

- Brushes for cleaning

- Soft cloths for wiping

- Drip oil cans for lubrication

- Calipers for measuring wear

With the right tools, checking and caring for your cutters is simple. Regular maintenance helps them last longer and work better.

What cleaning agents can I use for milling cutter maintenance?

You can use mild detergents, solvent-based cleaners, or degreasing agents to keep them clean. These products help to remove any build-up quickly and safely.

What are some essential tools needed for maintaining milling cutters?

Essential tools include cleaning brushes, soft cloths, and lubrication oils. They help to keep your milling cutters in the best condition.

FAQs on Milling Cutter Maintenance

Common questions and troubleshooting tips. Clarifying myths about milling cutter care.Got questions about keeping your milling cutter sharp and happy? Let’s clear things up! First, many wonder if cutting tools need oil. The answer? Yes! A little lubrication goes a long way. Some think they can skip cleaning; that’s a big no-no! Dust and chips bring chaos. Protective gear during maintenance is essential. Remember: safety first, fun second! Here’s a quick troubleshooting table to help you out:

| Issue | Solution |

|---|---|

| Dull cutter | Sharpen it or replace! |

| Uneven cuts | Check alignment! |

| Overheating | Add more coolant. |

Keep these tips in mind, and your milling cutter will thank you with flawless cuts!

Conclusion

In conclusion, a milling cutter maintenance checklist helps you keep your tools in top shape. Regular cleaning, proper storage, and timely inspections are essential. You should check for damages and sharpen blades as needed. By following this checklist, you ensure safety and improve performance. We encourage you to create your own checklist and read more about milling cutter care for better results!FAQs

What Are The Key Indicators That A Milling Cutter Needs Maintenance Or Replacement?You should check your milling cutter for sharpness. If it cuts slowly or leaves rough edges, it may need maintenance. Look for signs of wear, like cracks or chips. If it keeps breaking, it might be better to replace it. Regularly checking helps keep your machine working well.

How Often Should Milling Cutters Be Cleaned And Inspected For Optimal Performance?You should clean and inspect milling cutters often. It’s best to do this after every use. If you use them a lot, check them more often. Keeping them clean helps them work better and last longer.

What Specific Tools And Materials Are Required For Effective Milling Cutter Maintenance?To keep milling cutters in good shape, you need a few tools and materials. First, get a cleaning brush to remove dirt. Next, you will need a cloth to wipe them down. Use a measuring tool to check if they are still good. Finally, some oil helps to keep them from rusting.

What Steps Should Be Taken To Sharpen Or Recondition A Milling Cutter?To sharpen a milling cutter, you first need to clean it. Use a soft brush to remove any dirt. Then, you can use a sharpening tool to grind the edges carefully. After that, check if the cutter is sharp by feeling the edges. Finally, test the cutter on a piece of metal to see if it works well.

How Can Proper Milling Cutter Maintenance Improve Machining Accuracy And Prolong Tool Life?Taking care of milling cutters helps them work better. When we clean and sharpen them, they cut smoother and more accurately. This means our finished pieces are nicer and fit together well. Also, by maintaining them, we can use them for a longer time, saving money. So, good care makes our tools last and our work better!