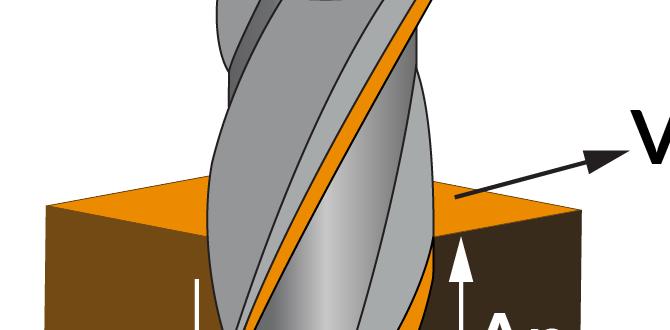

Have you ever wondered how machines make precise cuts? Milling cutters play a big role in this process. They shape metal, wood, and other materials. But did you know that these tools have limits? Understanding the milling cutter maximum engagement limits can help improve your work.

Picture this: you’re working on a project, and you need the perfect cut. You grab your milling cutter, excited to start. But what if you push it too hard? It could break or create a bad cut. That’s why knowing those limits is so important.

This article will explore what milling cutter maximum engagement limits mean. We’ll share tips to avoid mistakes and make your work easier. With the right knowledge, you can become a pro at using milling cutters!

Milling Cutter Maximum Engagement Limits: Key Insights And Tips

Milling Cutter Maximum Engagement Limits

Milling cutters play a key role in shaping materials. Did you know that each cutter has a specific engagement limit? This limit refers to how much material the cutter can handle safely. If you exceed it, you risk damaging the cutter or the workpiece. Learning about these limits can prevent costly mistakes. Also, using the right speed and feed rates can optimize performance. Have you checked the limits of your milling cutter lately? Keeping them in mind helps ensure smoother operations.Understanding Milling Cutters

Definition and types of milling cutters. Importance of selecting the right milling cutter for specific applications.Milling cutters are tools used for cutting shapes in materials like metal and wood. They come in many types, including flat cutters, ball nose cutters, and end mills. Choosing the right milling cutter is vital. It ensures smooth work and precise cutting. The wrong choice can damage the material or ruin the project.

Why is selecting the right milling cutter important?

Selecting the correct milling cutter can lead to better results. It helps create the shape you want and saves time. **Using the right tool makes a difference in quality.**

- Flat cutters: great for smooth surfaces.

- Ball nose cutters: perfect for rounded shapes.

- End mills: ideal for intricate designs.

In the end, understanding milling cutters helps in many projects. You can achieve amazing things with the right tools in hand.

Factors Influencing Engagement Limits

Material properties and their effects on milling performance. Cutter geometry and design considerations.Many things affect how well a milling cutter works. One big factor is the material properties. Harder materials can be tougher for cutters, while softer ones are easier to slice through. The shape of the cutter also plays a role. A well-designed cutter can reduce stress and boost efficiency. If a cutter looks like a pie, you want the right amount of slices for a perfect bite. This balance helps keep things running smoothly.

| Factor | Effect on Performance |

|---|---|

| Material Hardness | Harder materials can slow down cutting speed. |

| Cutter Shape | Better shapes reduce wear and tear. |

| Tool Design | Designed cutters create less friction. |

Calculating Maximum Engagement Limits

Key formulas and methods for determining engagement limits. Role of spindle speed and feed rate in calculations.Understanding how to calculate maximum engagement limits is essential for using milling cutters effectively. Key formulas help in finding these limits, making the process easier. Two important factors in these calculations are spindle speed and feed rate. Higher spindle speeds can increase productivity, but there’s a limit. Likewise, the feed rate must match the cutter’s capabilities for the best results. Healthy cutting practices keep tools sharp and machines running smoothly.

What are the key factors in calculating engagement limits?

Key factors include spindle speed, feed rate, and cutter specifications. Each of these elements works together to ensure productive milling. It’s like a dance where all parts must move together!

Important Points to Consider:

- Spindle Speed: Faster speeds can lead to more effective cutting.

- Feed Rate: Adjusting this can help maintain tool life.

- Cutter Specifications: Know your milling cutter’s limits.

Typical Engagement Limit Values

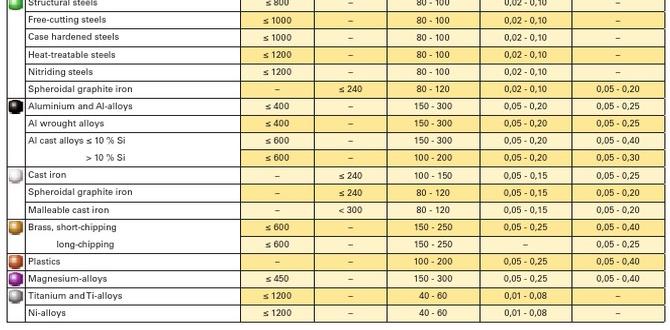

Industry standards for various materials. Comparison of engagement limits across different milling cutter types.Different materials need different tools for the best results. Industry standards help us know how to use milling cutters effectively. Here are some typical engagement limits:

- Aluminum: Up to 50% engagement

- Steel: About 40% engagement

- Brass: 30% engagement is common

- Plastic: 60% or more is often safe

Milling cutter types also have varying limits. For example, high-speed cutters can handle a higher load than standard ones. This means they can cut more efficiently and faster!

What are typical cutting engagement limits for milling cutters?

Engagement limits vary by material and cutter type. For aluminum, it’s usually up to 50%. In contrast, steel has a lower limit at about 40%. Each material needs tailored approaches for the best results.

Effects of Exceeding Engagement Limits

Potential damage to the workpiece and cutter. Impact on tool life and machining efficiency.Exceeding engagement limits can cause serious problems. Here’s what might happen:

- Damage to the workpiece: If limits are surpassed, the material may break or chip, ruining the project.

- Cutter wear: The milling cutter can dull quickly, leading to more replacements.

- Reduced tool life: Cutting tools work harder and wear out faster, costing more money.

- Lower machining efficiency: Too much force slows down production speed and affects quality.

Watching your cutter limits is key to safe and effective milling.

What happens if limits are exceeded?

Exceeding limits can lead to damage of the workpiece and cutter. This mistake lowers tool life and slows down machining efficiency, leading to extra costs and time lost. Always keep an eye on your settings!

Best Practices for Maximizing Engagement Limits

Techniques to optimize milling operations. Recommended settings based on material and cutter type.To get the best out of your milling cutter, try a few tricks! Start by adjusting the speed and feed rate based on the material you’re using. For softer materials, like aluminum, go faster; for harder stuff, slow it down a bit to save your cutter and sanity. Remember, too much engagement can lead to disaster! Always check the cutter type to find its sweet spot. Here’s a handy table:

| Material | Cutter Type | Speed (RPM) | Feed Rate (IPM) |

|---|---|---|---|

| Aluminum | High-Speed Steel | 8000 | 50 |

| Steel | Cobalt | 2000 | 20 |

| Stainless Steel | Carbide | 1500 | 10 |

By using the right settings, you can boost performance without risking damage. It’s like avoiding a bad haircut by choosing a good barber! Who doesn’t want a smooth operation?

Case Studies and Examples

Realworld applications showcasing effective engagement limit management. Lessons learned from failures due to poor engagement limit adherence.Many businesses have faced problems because they didn’t stick to their engagement limits. These issues can cause delays and extra costs. Learning from their mistakes helps everyone do better. Real-world examples show the importance of following the rules. Here are two key points:

- Effective engagement limit management: Companies that follow their cutting limits have smoother operations and lower costs.

- Consequences of poor adherence: Failing to respect engagement limits can lead to equipment damage and safety risks.

By sharing these case studies, we can learn and avoid similar mistakes in the future.

What are real-world examples of engagement limit management?

Companies apply strict limits to avoid problems. This keeps costs low and productivity high.Future Trends in Milling Cutter Technology

Innovations in milling cutter designs and materials. Predictions for engagement limit advancements in the machining industry.The future of milling cutter technology looks bright! New designs and materials are emerging. These innovations help tools last longer and cut better. Some materials are lighter and more durable. This means quicker machining and improved results. Predictions show that engagement limits may rise, pushing the machining industry forward. Imagine how effective these tools will be in just a few years!

What materials are being used in new milling cutter designs?

New milling cutter designs use advanced materials like carbide, ceramic, and coated steels. These materials improve cutting speed and tool life significantly.

Key Trends in Milling Cutter Technology:

- Stronger materials for durability

- Lightweight designs for faster machining

- Smart technology for efficiency

Conclusion

In conclusion, understanding milling cutter maximum engagement limits is crucial for effective machining. These limits help you avoid tool breakage and achieve precise cuts. Remember, balance speed and depth for best results. We encourage you to explore more about milling techniques to enhance your skills. Keep practicing, and you’ll improve your confidence in using milling cutters!FAQs

Sure! Here Are Five Related Questions About Milling Cutter Maximum Engagement Limits:Milling cutters help shape materials like metal or wood. The maximum engagement limit is how deep they can cut without breaking. It’s important to know this to avoid damaging the cutter. If we cut too deep, it can wear out faster. So, we need to be careful and follow the limits.

Sure! Please ask your question, and I’ll give you a short answer.

What Factors Influence The Maximum Engagement Limits Of A Milling Cutter During Operation?The maximum engagement limits of a milling cutter depend on a few important factors. First, the type of material being cut matters. Softer materials allow more cutting while harder ones limit it. Second, the shape and size of the cutter itself can change how deep it can go. Lastly, the speed and force we use while cutting also affect how much we can engage the cutter safely.

How Do Different Materials Being Machined Affect The Optimal Engagement Limits For Milling Cutters?Different materials change how we use milling cutters. Hard materials like steel can break cutters if we push too hard. Softer materials, like plastic, let us cut faster without damage. So, we need to adjust how deeply and quickly we cut depending on the material. This helps keep our tools safe and makes better cuts.

What Are The Consequences Of Exceeding The Maximum Engagement Limits On A Milling Cutter’S Performance And Lifespan?Exceeding the maximum limits for a milling cutter can hurt how well it works. It can cause the cutter to wear out faster. This means you may need to replace it sooner. Also, it could make the cut less smooth and mess up your project. So, it’s important to follow limits to keep things running well!

How Can Adjustments To Feed Rate And Spindle Speed Help In Maintaining Optimal Engagement Limits For Milling Cutters?Adjusting the feed rate and spindle speed helps us keep the milling cutter working well. The feed rate is how fast the cutter moves through the material. Spindle speed is how fast the cutter spins. By changing these two, we can make sure the cutter cuts smoothly without getting stuck or breaking. This way, we get better results and save tools!

What Tools Or Techniques Are Available To Calculate And Monitor The Maximum Engagement Limits During Milling Operations?To calculate and monitor maximum engagement limits during milling, we can use special software tools. These tools help us see how fast and deep we can cut. We can also use sensors that track the machine’s performance while it works. By looking at the data from these tools, we can make sure we are safe and efficient while milling.