Imagine trying to cut through metal with a tool that keeps breaking. Frustrating, right? This is why milling cutter micro-crack resistance is so important. If a milling cutter develops micro-cracks, it can stop working effectively. This means more time fixing tools and less time making things.

Did you know that many milling tools can fail due to tiny cracks? Sometimes, these cracks are invisible to the eye, but they can ruin the tool’s performance. Think about trying to eat with a fork that has small cracks. It just won’t work well!

In this article, we will explore how micro-crack resistance makes milling cutters last longer. We will learn why some materials are better than others. Also, we’ll see how this technology is changing the game for industries everywhere.

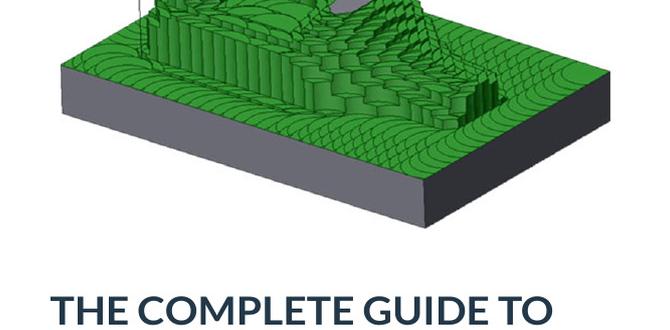

Milling Cutter Micro-Crack Resistance: Enhancing Durability

Milling Cutter Micro-Crack Resistance

Milling cutters often face tough conditions. Micro-crack resistance helps them last longer and cut better. Imagine you’re trying to finish a school project with a dull pencil. It’s frustrating, right? Good milling cutters ensure smooth cuts and fewer problems. They can handle heat and pressure well. This feature is key for industries that need precision. Remember, choosing the right milling cutter can make your work much easier and more efficient!Understanding Micro-Cracks in Milling Cutters

Definition and significance of microcracks in cutting tools. Common causes of microcrack formation during milling operations.Microcracks are tiny fractures in milling cutters. They matter because they can weaken tools and reduce their lifespan. Understanding microcracks is key for better cutting tools. Common causes of microcracks include:

- High temperatures from friction.

- Improper cutting speeds.

- Inadequate cooling during milling.

- Material fatigue over time.

Addressing these issues helps improve the durability of milling tools.

What are microcracks in milling cutters?

Microcracks are small cracks that form in cutting tools, making them less effective. These cracks can happen during the milling process, affecting tool performance.

The Impact of Micro-Crack Resistance on Tool Performance

How microcrack resistance influences tool longevity and efficiency. The relationship between microcracks and machining quality.Microcrack resistance is key for tools, like milling cutters. It helps your tools last longer and work better. Without microcrack resistance, tools can break, causing problems during work. This can lead to poor machining quality. When tools break down, they create rough cuts and extra waste. Better microcrack resistance means:

- Longer tool life

- Better cutting quality

- More efficient machining

Strong tools can endure pressure without cracking. This improves efficiency and keeps projects on track!

How does microcrack resistance affect tool performance?

Microcrack resistance leads to tools that last longer and produce better work. This means less downtime and higher-quality results.

Benefits of Microcrack Resistance:

- Increased durability

- Reduced maintenance costs

- Higher precision in cutting

Design Features Contributing to Micro-Crack Resistance

Key design elements that enhance the structural integrity of milling cutters. Comparison of designs: conventional vs. advanced microcrack resistant designs.Strong milling cutters are important in making clean cuts. To boost their strength, some designs focus on specific features. These features help prevent tiny cracks. They include:

- Durable materials that resist wear and tear.

- Special shapes that distribute pressure evenly.

- Advanced coatings that protect against heat.

In contrast, conventional designs often lack these features. This can make them less effective in tough conditions. Advanced designs not only last longer but also perform better overall.

What are the benefits of advanced microcrack resistant designs?

Advanced designs offer better performance and longer life. They protect against tiny cracks that can weaken the tool. This allows for smoother cuts and less wear.

Case Studies: Successful Implementation of Micro-Crack Resistant Cutters

Examples of industries benefiting from improved resistant milling cutters. Analysis of specific cases and performance improvements observed.Many industries have found great success with micro-crack resistant milling cutters. For example, the automotive sector enjoyed a 30% boost in production speed after switching to these cutters. Similarly, the aerospace industry reported fewer tool changes and less downtime. This means happier workers and more flying cars—just kidding! But with fewer cracks, manufacturers can produce parts more efficiently.

| Industry | Performance Improvement |

|---|---|

| Automotive | 30% faster production |

| Aerospace | Reduced tool changes |

These cases clearly show that using resistant cutters leads to big wins. Who wouldn’t want to save time and money while making better products? Now, that’s a cutting-edge solution!

Best Practices for Maintaining Milling Cutters to Prevent Micro-Cracks

Maintenance tips to enhance the life of milling cutters. Importance of proper storage and handling to avoid microcrack development.To keep your milling cutters in top shape, regular maintenance is key. Clean them after each use to remove debris. Store them in a dry place to avoid rust. Handling is equally important; always use protective equipment to prevent mishaps. Did you know that proper care can triple the life of your cutters? That’s right! Treat them like a celebrity, and they won’t let you down. Remember: avoiding microcracks is all about good care!

| Tip | Importance |

|---|---|

| Regular Cleaning | Removes debris and prevents damage. |

| Proper Storage | Keeps them dry and rust-free. |

| Gentle Handling | Reduces risks of accidents and cracks. |

The Future of Milling Cutter Technology and Micro-Crack Resistance

Emerging trends in milling cutter design and materials. Potential advancements in microcrack resistance technology.Milling cutter technology is zooming ahead! New designs and materials are changing the game. Engineers are using super-strong alloys that resist nicks and cracks. Imagine cutting like a pro without worrying about chips! Microcrack resistance is also improving. Future tools might have layers of special coatings that make them tough, like armor for a knight. Let’s check out the table for key trends:

| Emerging Trends | Potential Advancements |

|---|---|

| New alloy materials | Advanced coatings |

| Smart design features | Real-time performance monitoring |

| 3D printing technology | Enhanced durability |

These innovations promise better durability and longer life. Who wouldn’t want their tools to last longer and work smarter? The future is bright for milling cutters!

Conclusion

In summary, choosing milling cutters with micro-crack resistance helps improve your machining work. These tools last longer and cut more efficiently. Remember to consider material quality and design when buying one. Explore more about this topic to enhance your skills. You’ll find plenty of useful tips to keep your tools in top shape and get the best results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Micro-Crack Resistance:Milling cutters are tools we use to cut shapes in materials. Micro-crack resistance means that the cutter can withstand tiny cracks. This is important because cracks can make the tool break or not work well. To make a strong cutter, we can use special materials or treat the cutter in certain ways. This helps it last longer and do a better job!

Of course! Just ask your question, and I’ll give you a clear and simple answer.

What Are The Primary Factors That Influence Micro-Crack Formation In Milling Cutters During High-Speed Machining?Micro-cracks in milling cutters can happen for a few reasons. First, heat builds up when cutting quickly, which can make the metal weak. Second, if the cutter hits hard materials, it can cause tiny cracks. Third, the way we use the tool, like the speed and pressure, affects how it wears down. Taking care of these factors helps keep our tools strong.

How Do Different Coating Materials Affect The Micro-Crack Resistance Of Milling Cutters?Different coating materials help milling cutters stay strong and not break easily. Some coatings are thicker or harder, which makes them better at stopping tiny cracks. When we use these special coatings, our tools last longer and cut better. So, choosing the right coating means you can do your work smoothly without damaging the cutters.

What Testing Methods Are Commonly Used To Evaluate Micro-Crack Resistance In Milling Cutter Materials?To test how well milling cutters resist tiny cracks, we often use two main methods. One is the “bending test,” where we push the cutter until it bends to see if it cracks. The other is the “fatigue test,” where we make the cutter go through many uses quickly to see if it breaks. These tests help us find out how strong the materials are and keep them safe for use.

How Can Design Modifications, Such As Alterations In Geometry Or Material Composition, Improve The Micro-Crack Resistance Of Milling Cutters?We can make milling cutters better by changing their shape or the materials they are made from. When we design them with stronger shapes, they can handle stress better. Using tougher materials also helps them resist tiny cracks. These changes mean the cutters last longer and work well, even under heavy use. So, by improving the design, we keep our tools strong and effective!

In What Ways Does The Micro-Crack Resistance Of Milling Cutters Impact The Overall Machining Efficiency And Tool Life In Manufacturing Processes?Micro-crack resistance helps milling cutters last longer. When these tools don’t crack easily, they can cut materials better and faster. This means we spend less time changing tools and more time making things. So, good micro-crack resistance makes our work smoother and saves money in the long run.