Have you ever wondered how machines cut and shape hard materials? It’s all thanks to milling cutters. These tools are key in many factories and workshops. They help create everything from car parts to toys. But how do you know which milling cutter to pick?

In this article, we dive into the milling cutter performance index guide. This guide helps you understand different milling cutters. It explains why some are faster or last longer than others. You’ll discover what makes a milling cutter truly great.

Imagine you’re building a small robot. You want the best parts, right? Knowing the milling cutter performance index can make a big difference. Using the right tool can mean the difference between success and failure in your projects.

Get ready to learn some fun facts about milling cutters and how they work. You’ll see why these tools are so important in making things we use every day. Let’s explore together!

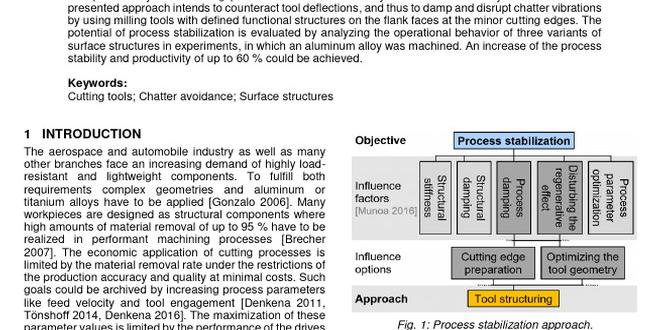

Comprehensive Milling Cutter Performance Index Guide

Milling Cutter Performance Index Guide

The milling cutter performance index guide helps you understand how well milling cutters work. It shows how different cutters perform under various conditions. Knowing this can save time and money during projects. Have you ever wondered why some cuts are smoother? The index can reveal those secrets. A surprising fact is that the right cutter choice can improve surface finish significantly. This guide makes it easier to pick the best tools for every job!Understanding Milling Cutters

Definition and types of milling cutters. Importance of milling cutters in manufacturing processes.Milling cutters are tools used in machining. They shape materials by removing unwanted parts. There are types of milling cutters, including:

- Face cutters

- End mills

- Slot drills

- Ball nose cutters

What are the types of milling cutters?

The common types of milling cutters include face cutters, end mills, and slot drills. Each type serves a special purpose in cutting.

Factors Affecting Milling Cutter Performance

Material composition of the cutter. Geometry and design features.Many things influence how well a milling cutter works. First, the material of the cutter matters. For example, high-speed steel (HSS) is tough but not as hard as carbide. Carbide cutters can last longer and cut faster, which is a big plus! Next, we have geometry and design features. The shape and angles of the cutter impact how easily it can slice through materials. Think of it like a superhero with the right tools—sharp and ready to go!

| Material | Durability | Speed |

|---|---|---|

| High-Speed Steel | Moderate | Good |

| Carbide | High | Very Good |

Measuring Milling Cutter Performance

Key performance indicators (KPIs) to consider. Methods to evaluate cutter efficacy.When it comes to measuring how well a milling cutter performs, there are some key points to keep in mind. First, you need to look at different Key Performance Indicators (KPIs). These include cutting speed, tool life, and surface finish. Next, consider methods to evaluate cutter effectiveness. Testing the cutter on different materials and measuring the results is a great start. Here’s a quick table to help you think about these factors:

| Performance Indicator | What to Measure |

|---|---|

| Cutting Speed | How fast it cuts through material. |

| Tool Life | How long the cutter lasts before needing to be replaced. |

| Surface Finish | How smooth the final product is. |

By keeping an eye on these indicators, you can make sure your milling cutter is doing its job well. Think of it like checking if your favorite toy still works—if it doesn’t, it’s time for a new one!

Optimizing Milling Cutter Performance

Techniques for enhancing cutting efficiency. Tools and technology to monitor performance.To improve how milling cutters work, we can use smart techniques and tools. Efficiency is key! Here are some tips:

- Choose the right cutter.

- Adjust feed rates and speeds.

- Keep tools clean and sharp.

Using technology helps, too. You can monitor cutter performance through:

- Real-time sensors.

- Data tracking software.

- Performance dashboards.

These tools make it easy to spot problems and boost performance!

How can I enhance milling cutter efficiency?

To enhance milling cutter efficiency, focus on the right tools and monitoring systems. Adjust your strategies based on real-time data for the best results.

Common Issues in Milling Cutter Usage

Identifying wear and tear in cutters. Troubleshooting performance problems.Milling cutters can face problems over time. This wear and tear affects how well they work. Identifying issues quickly is important. Look for these signs of damage:

- Chips or cracks on the cutting edge.

- Unusual noise during operation.

- Increased heat while cutting.

Troubleshooting is key to keeping them sharp. Check the machine settings and the cutter condition. Regular maintenance can prevent many issues. Always act if you notice something strange.

What are common problems with milling cutters?

Common problems include poor cutting, excessive heat, and loud noises. These issues often arise from wear and tear, machine settings, or lack of maintenance.

Case Studies: Milling Cutter Performance in Action

Successful applications in different industries. Lessons learned from performance analysis.Look at how milling cutters shine in various industries! In the auto world, they shape parts like magic. They help factories by making pieces faster and at a lower cost. In aerospace, precision is key; these cutters ensure parts fit just right. After analyzing, we learned that the right cutter choice can save time and money. A funny saying goes, “Cut it out, but make it perfect!” That’s what helps both teams and machines run smoothly.

| Industry | Successful Application | Lesson Learned |

|---|---|---|

| Automotive | Fast part production | Right cutter means more savings |

| Aerospace | High precision parts | Accuracy is everything! |

Future Trends in Milling Cutter Technology

Innovations in materials and design. Predictions for milling cutter performance advancements.Exciting changes are coming to milling cutter technology! New materials like super-strong carbides are being used, making cutters last longer and cut faster. Designers are thinking outside the box (or the cutter, rather) to create shapes that improve performance. Predictions suggest that future milling cutters will reduce waste by 50% and increase efficiency significantly. Who knows? We might soon have cutters that can slice through metal like a hot knife through butter!

| Trends | Impact |

|---|---|

| Advanced Materials | Longer life, better cutting |

| Innovative Designs | Improved performance |

| Predictive Technology | Less waste and more speed |

Conclusion

In summary, the milling cutter performance index guide helps you understand how to choose and use milling cutters effectively. It highlights the importance of speed, feed rate, and tool material. You can improve your projects by applying these insights. For better results, explore more resources or tools that enhance cutter performance. Let’s keep learning together!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Performance Index:Sure! A milling cutter is a tool used in machines to cut and shape materials. The performance index helps us understand how well the cutter works. It shows how fast and accurately the cutter can cut through stuff. A higher performance index means the cutter works better. We want our tools to be strong and efficient!

Sure! Feel free to ask your question, and I’ll do my best to give you a short and clear answer!

What Factors Influence The Performance Index Of A Milling Cutter In Different Machining Environments?The performance index of a milling cutter can be affected by a few things. First, the material you are cutting matters; softer materials are easier to cut. Also, the speed and pressure used during cutting play a big role. Finally, the type of tool coating can help the cutter last longer and work better. All these factors work together to decide how well the cutter performs.

How Can The Cutting Speed And Feed Rate Affect The Milling Cutter’S Performance Index?Cutting speed is how fast the cutter spins, while feed rate is how quickly the cutter moves through the material. If you set the cutting speed or feed rate too high, the cutter can get too hot or wear out quickly. If it’s too low, it might not cut well or take too long. Finding the right balance helps the cutter work better and last longer. This makes our work easier and saves time!

What Are The Methods For Evaluating And Comparing The Performance Indices Of Various Milling Cutter Materials?To compare how well different milling cutter materials work, we can try a few methods. First, we can look at how fast they cut materials. We can also check how long they last before wearing out. Another way is to see how smooth their cuts are. Finally, we can measure how much heat they produce while cutting. These tests help us understand which materials are the best.

How Does Tool Geometry, Such As Flute Design And Rake Angle, Impact The Performance Index Of Milling Cutters?The shape of a milling cutter affects how well it cuts. Flute design helps the cutter move chips away so it doesn’t get stuck. Rake angle, which is the angle of the cutting edge, helps the cutter slice smoothly. When these features are right, the cutter works better and lasts longer. Better tools mean better results for us!

In What Ways Can Advancements In Coating Technologies Improve The Performance Index Of Milling Cutters?Advancements in coating technologies can make milling cutters last longer and work better. These special coatings help the cutters stay sharp and resist wear. When the cutters are strong, they can cut materials more easily and quickly. This means we can get more done and make better products. Overall, better coatings help us work smarter and faster!