Have you ever wondered how a milling cutter works? It’s fascinating to think about. When the blade spins, it creates pressure on the material being cut. But what exactly happens to that pressure? This is where the milling cutter pressure distribution curve comes into play.

Imagine slicing through a piece of cake. The way the knife pushes against the cake helps you cut through it smoothly. In milling, the cutter must distribute its pressure evenly. If it doesn’t, the cut could end up uneven or messy.

Many people don’t realize how important this curve is for engineers and designers. It helps them understand how to improve the cutting process. They can make machines that cut better and faster.

In this article, we’ll explore the milling cutter pressure distribution curve. We’ll see how it impacts everything from efficiency to the quality of the final product. Get ready to dive into the world of milling! You might be surprised by what you learn.

Milling Cutter Pressure Distribution Curve Explained For Machining

Milling Cutter Pressure Distribution Curve

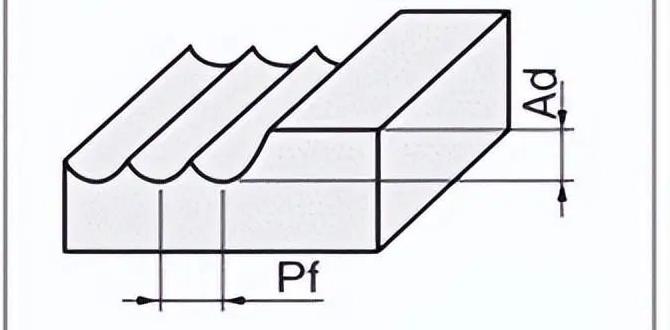

Have you ever wondered how milling cutters work? The milling cutter pressure distribution curve shows how the pressure changes as the cutter moves through the material. It helps us understand how much force the cutter applies in different spots. This information is crucial for creating smoother cuts and longer-lasting tools. Knowing this can help engineers design better machines that save time and money. By analyzing the curve, we can improve the efficiency and effectiveness of machining processes.Importance of Pressure Distribution in Milling Operations

Effects of pressure distribution on tool wear. Impact on the quality of the finished product.Pressure distribution is key in milling. It affects how quickly tools wear out. When pressure is uneven, some parts wear faster than others. This can lead to more breakage and replacement costs.

Quality is also important. If pressure is not balanced, the finished item can end up rough or uneven. This can cause wasted materials and time.

- Even pressure extends tool life.

- Balanced pressure leads to better quality products.

- Good pressure saves money in the long run.

How does pressure distribution affect tool wear?

Uneven pressure can cause tools to wear out faster, leading to more replacements and increased costs.

What impact does it have on product quality?

Unbalanced pressure may result in rough surfaces and poor finishes, wasting materials and time.

Key Factors Influencing Pressure Distribution

Material properties of the workpiece. Cutter geometry and design considerations.Several key factors affect how pressure is spread out in mills. Material properties of the workpiece matter a lot. Hard materials will give more resistance than soft ones. The design of the cutter also plays a big role. A well-designed cutter cuts better and spreads pressure evenly. Here are other things to think about:

- Blade shape and angle

- Number of flutes

- Cutting speed

In the end, understanding these factors helps create better tools.

What are the main factors that affect pressure distribution?

Material properties and cutter design are the main factors. They influence how pressure distributes during milling.

Real-World Applications of Pressure Distribution Analysis

Case studies demonstrating improvements in manufacturing. Benefits of optimizing pressure distribution in various industries.Pressure distribution analysis can really shake things up in manufacturing! For instance, a company that used this method cut costs by 20% and boosted output by 30%. That’s like finding extra fries at the bottom of the bag! Companies that optimize their pressure distribution often see better efficiency, fewer defects, and happier workers. Below is a table showing some cool benefits across different industries:

| Industry | Improvement |

|---|---|

| Automotive | 15% faster production |

| Aerospace | 10% weight reduction |

| Electronics | 20% lower failure rates |

These numbers show how pressure distribution analysis can create real magic! It’s like giving your milling cutter a superpower!

Future Trends in Milling Cutter Pressure Distribution Research

Emerging technologies and methodologies. Predictions for advancements in milling cutter design and performance.In the world of milling cutters, excitement brews over new technologies. Advancements like AI and 3D printing are turning dreams into reality. Imagine designing a milling cutter that learns as it works! Researchers predict that designs will improve, leading to better performance and efficiency. Enhanced materials could also make cutters last longer while cutting costs. Don’t be surprised if your future cutter jokes about its own sharpness!

| Emerging Technologies | Potential Benefits |

|---|---|

| AI Integration | Smart cuts, less waste |

| 3D Printing | Custom designs on demand |

| Advanced Materials | Stronger and longer-lasting |

Common Challenges and Solutions in Analyzing Pressure Distribution

Typical obstacles faced by engineers and researchers. Strategies for overcoming these challenges.Engineers often face some fun challenges while analyzing pressure distribution. One major hurdle is getting accurate data from different sources. Sometimes, it feels like finding a needle in a haystack! Another issue is managing complex calculations. It can be confusing, like trying to solve a Rubik’s Cube blindfolded.

To tackle these challenges, teamwork can be the best strategy. Sharing ideas makes everything easier. Also, using software tools can simplify calculations. They are like having a super-smart sidekick! Regular training keeps everyone updated with new techniques, helping them become experts.

| Challenges | Solutions |

|---|---|

| Inaccurate data | Collaborate with experts |

| Complex calculations | Use advanced software |

| Limited knowledge | Ongoing training sessions |

Remember, every challenge is an opportunity in disguise! So let’s tackle those problems with a smile!

Conclusion

In summary, the milling cutter pressure distribution curve shows how pressure varies over the cutter. Understanding this curve helps improve cutting efficiency and tool lifespan. We can see that better pressure distribution leads to smoother cuts. Next, you can explore how different materials affect this curve or read about ways to optimize your cutting process. Keep learning and experimenting!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutter Pressure Distribution Curve:Sure! A milling cutter is a tool we use to cut shapes from materials like wood or metal. The pressure distribution curve shows how the force spreads out when the cutter is working. This helps us understand where the cutter cuts best. We want the pressure to be even so the cutting is smooth. If one part has too much pressure, it can break or wear out faster.

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Pressure Distribution Along The Cutting Edges Of A Milling Cutter During Operation?The pressure on a milling cutter changes because of a few main things. First, the speed of the cutter matters. If it spins faster, the pressure is different. Second, the type of material we are cutting affects how much pressure is needed. Finally, how deep we cut into the material also changes the pressure on the edges.

How Can The Pressure Distribution Curve Be Used To Predict Tool Wear And Failure In Milling Applications?We can use the pressure distribution curve to see how much force is on the tool while it cuts. When the pressure is high, the tool can wear out faster. By looking at the curve, we can find out when the tool will break or need to be replaced. This helps us save time and money while working. It’s like keeping track of how tired you feel during a long run.

What Is The Relationship Between Cutting Speed, Feed Rate, And The Resulting Pressure Distribution On A Milling Cutter?When we use a milling cutter, cutting speed and feed rate affect how much pressure is on the cutter. Cutting speed is how fast the tool spins, while feed rate is how quickly we move the material into the cutter. If we increase the cutting speed, we often need a slower feed rate to keep things balanced. If we feed the material too quickly, it can create too much pressure and cause damage. So, finding the right balance is important for smooth cutting.

How Does The Geometry Of A Milling Cutter Affect Its Pressure Distribution During Cutting Processes?The shape of a milling cutter helps it cut better. When the cutter has sharp edges, it puts less pressure on the material. This means the cutter can move smoothly and cut easily. If the edges are dull or curved, it puts more pressure, making it harder to cut. So, a good shape helps us cut with less effort.

What Experimental Methods Or Modeling Techniques Are Commonly Used To Analyze And Visualize The Pressure Distribution Curve In Milling Operations?To study pressure in milling, we can use some cool methods. One way is to use special sensors that measure the pressure directly. We can also create computer models to see how pressure changes during milling. Another method is to make graphs that show the pressure at different points. These tools help us understand what happens when we cut materials.