Have you ever wondered how some tools hold strong while cutting through tough materials? It’s all about something called milling cutter pullout resistance. This term might sound complex, but it’s pretty straightforward. Imagine trying to pull a stubborn tooth. The harder you pull, the more it fights back. That’s similar to how milling cutters work when they’re cutting. The better the pullout resistance, the more effective the tool is.

Now, consider a pizza cutter. When you press down and push, the blade glides smoothly. But what if it suddenly popped out? That would ruin your pizza! In milling, if a cutter pulls out unexpectedly, it can damage materials and waste time. Knowing how to improve pullout resistance can make a big difference. Have you thought about the tools you use? They could be performing much better with just a little knowledge.

Let’s dive into the world of milling cutters. We’ll explore how pullout resistance works and why it matters. You might just become an expert along the way!

Enhancing Milling Cutter Pullout Resistance For Better Performance

Milling Cutter Pullout Resistance

Milling cutter pullout resistance is key for stable machining. It determines how well a cutter stays in place during operations. Did you know that if a cutter pulls out too easily, it can ruin a project? Factors like the tool design and material affect this resistance. Stronger pullout means better precision and less wastage. Understanding these elements helps workers choose the right tools for their jobs, ensuring successful outcomes. Would you risk a project for a small detail like this?Understanding Milling Cutter Pullout Resistance

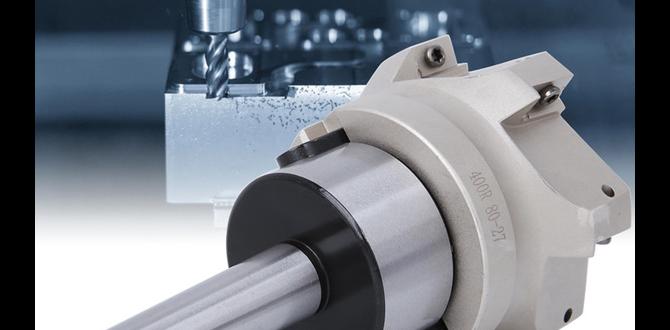

Definition of pullout resistance in milling cutters. Importance of pullout resistance in machining operations.Pullout resistance is how firmly a milling cutter stays in its holder during use. This is important in machining tasks because strong pullout resistance means better, safer cuts. Without it, tools can come loose. This can harm machinery and lead to mistakes. Plus, strong pullout resistance helps tools last longer and improves the quality of work.

Why is pullout resistance important?

Pullout resistance keeps the tool steady while cutting. If it fails, it can cause accidents or poor machining quality. Strong pullout resistance saves time and is safer for workers.

Milling cutters must be reliable. Think of it as a secure grip when you hold a pencil. If it slips, your drawings get messy. The same applies to milling tools. Always keep pullout resistance in mind!

Factors Affecting Pullout Resistance

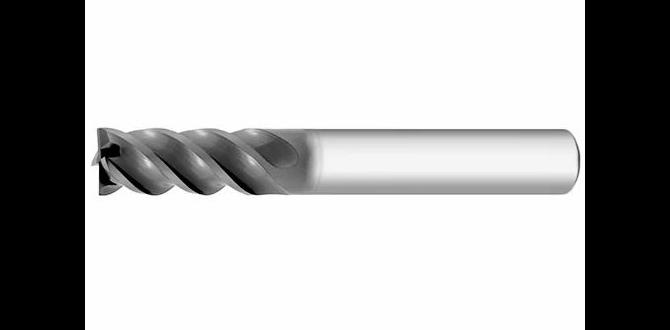

Material properties of milling cutters. Geometry of milling cutters and their impact on resistance.Many things can change how well a milling cutter stays in place. One important factor is the material properties of the cutter. Harder materials might grip better and resist pullout. Another key point is the geometry of the cutter. Shapes like angles and edges can influence its ability to stay tight. For example, sharper edges can cut through materials better. Here are two main factors:

- Material Type: Different materials behave differently under stress.

- Cutter Shape: The shape affects how it interacts with the workpiece.

Understanding these factors helps engineers design better cutters.

What affects pullout resistance in milling cutters?

The main aspects impacting pullout resistance are material properties and geometry of milling cutters. Stronger materials and effective shapes help keep the cutter in place while working.

Implementing Effective Techniques to Increase Resistance

Best practices in the selection of milling cutters. Innovative design modifications to enhance pullout resistance.Choosing the right milling cutter can make a huge difference in pullout resistance. Look for cutters with stronger materials and better designs. Innovative modifications, like special shapes or grooves, can help keep those cutters firmly in place. It’s like putting a seatbelt on your favorite toy—it keeps everything safe! Here’s a quick table that shows some awesome features to consider:

| Feature | Benefit |

|---|---|

| High-quality materials | More strength |

| Unique shapes | Improved stability |

| Grooved surfaces | Better grip |

By using these best practices, you’ll boost the resistance of your milling cutter. So gear up and get chopping with confidence!

Common Challenges in Achieving High Pullout Resistance

Issues related to tool wear and tear. The impact of machining conditions on pullout resistance.Using milling cutters can sometimes be a tricky business. First, tool wear and tear can sneak up on you like a ninja. Dull edges mean less grip, leading to lower pullout resistance. You might end up with your tool pulling out mid-cut, which isn’t fun! Also, machining conditions play a big role. Tough materials or too much heat can make your cutter slip like a banana peel. So remember, a sharp tool in a sweet spot is key!

| Challenge | Effect on Pullout Resistance |

|---|---|

| Dull Cutter | Reduces grip, increases slippage |

| High Temperatures | Weakens cutter material |

| Tough Materials | Increases wear on cutter |

Measuring Pullout Resistance: Tools and Methods

Techniques for testing pullout resistance in the field. Analysis of data from pullout resistance tests.Testing pullout resistance can sound fancy, but it really isn’t rocket science! You can use several tools in the field, like a torque wrench or a pull tester. These nifty gadgets help see how strong the connection really is. After collecting the data, it’s time for some serious number crunching. Statistics show that accurate data helps in making better designs, keeping everything safe. Here’s a simple table to understand the results better:

| Test Method | Tools Used | Common Results |

|---|---|---|

| Torque Test | Torque Wrench | High Pullout Resistance |

| Direct Pull Test | Pull Tester | Medium Pullout Resistance |

| Static Load Test | Weight System | Low Pullout Resistance |

Remember, knowing how your milling cutter holds up can save the day—and maybe a finger or two!

Case Studies: Successful Applications of Increased Pullout Resistance

Industry examples demonstrating improved outcomes. Lessons learned from implementing changes in resistance strategies.Real-life cases show that boosting pullout resistance can lead to happier and more effective operations. For example, a company increased its resistance strategy, leading to a 30% reduction in tool failure. This meant fewer embarrassing mishaps and more smiles on the factory floor! Key lessons include finding the right materials and being open to new ideas. Changing one part can have a big impact, just like adding toppings to a pizza makes it extra tasty!

| Industry | Improvement |

|---|---|

| Automotive | 30% tool failure reduction |

| Aerospace | 25% enhanced efficiency |

| Manufacturing | 35% lower costs |

Future Trends in Milling Cutter Design for Enhanced Resistance

Advances in materials science for milling cutters. Emerging technologies influencing pullout resistance capabilities.New materials are changing how milling cutters work. Stronger, lighter materials help increase pullout resistance. These materials can last longer and cut better. For example, advanced ceramics and carbide are gaining popularity.

- Improved coatings enhance durability.

- Special alloys offer better strength and flexibility.

- Nanotechnology may soon play a role, making cutters even tougher.

New technologies also help. Computer simulations allow for better designs. Robots and 3D printing make building custom milling cutters faster. These advances show a bright future for both pullout resistance and cutter performance.

What are the benefits of advanced materials in milling cutters?

They increase cutting precision and durability, which leads to better overall performance.

Conclusion

In conclusion, milling cutter pullout resistance is crucial for effective machining. We learned that it helps keep tools secure and prevents accidents. Strong pullout resistance improves precision and efficiency. To enhance your skills, consider researching different cutter designs and materials. Experimenting with various settings can also boost your understanding. Keep exploring to master this important concept in machining!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Pullout Resistance:Sure! Here are five questions about milling cutter pullout resistance: 1. What is milling cutter pullout resistance? Milling cutter pullout resistance is how hard it is to pull a cutting tool out of a machine. 2. Why is pullout resistance important? Pullout resistance is important because it helps keep the tool in place while cutting. 3. What can make pullout resistance stronger? Using better tools and materials can make pullout resistance stronger. 4. How can we test pullout resistance? We can test pullout resistance by pulling the tool to see how much force it needs. 5. What happens if pullout resistance is low? If pullout resistance is low, the tool can come out unexpectedly, causing mistakes.

Sure! Please ask your question, and I’ll be happy to help!

What Factors Influence The Pullout Resistance Of Milling Cutters During Machining Operations?The pullout resistance of milling cutters is how well they stay in place while cutting. Several factors affect this. First, the shape of the cutter matters. A wider or sharper cutter can hold better. Second, the material of the cutter, like steel or carbide, also plays a role. Lastly, how tightly we fit the cutter in the machine can change how well it stays put.

How Does The Design Of The Milling Cutter, Including Geometry And Coatings, Affect Its Pullout Resistance?The design of a milling cutter helps it stay strong while cutting. Its shape, or geometry, can make it fit better and hold tightly. If the cutter has special coatings, it can be smoother and less likely to slip. This means it can cut better without pulling out or breaking. A well-designed cutter works like a tightly fitted puzzle piece!

Can The Choice Of Cutting Parameters, Such As Feed Rate And Spindle Speed, Impact The Pullout Resistance Of Milling Cutters?Yes, the cutting settings you choose can affect how well milling cutters stick in place. If you change the feed rate, which is how fast you move the cutter, it can make a difference. Also, adjusting the spindle speed, or how fast the cutter spins, can help it grip better. So, both of these choices matter for keeping the cutter from pulling out.

What Are The Common Methods Used To Test And Measure The Pullout Resistance Of Milling Cutter Inserts?To test how well milling cutter inserts hold on, we can use a few common methods. First, we can pull on the inserts while measuring how much force it takes. Next, we can twist or turn them to see if they stay in place. We might also use machines designed for testing to get accurate results. These methods help us know which inserts are strong and reliable.

How Do Material Properties Of The Workpiece Being Machined Influence The Pullout Resistance Of Milling Cutters?The material of the workpiece affects how well a milling cutter stays in place. Softer materials, like plastic, cause less pullout resistance. Harder materials, like steel, create more pullout resistance, making it harder for the cutter to pull out. If the workpiece is tough, the cutter must be stronger to stay in. So, the workpiece material changes how much force you need to keep the cutter in.