Have you ever wondered how machines carve out metal shapes? One important tool in this process is the milling cutter. But what happens during the cutting? Things like radial cutting forces can affect how well the cutter works.

Imagine you’re playing with a toy that cuts through Play-Doh. If you push too hard, it might get stuck. The same idea applies to real milling cutters. Understanding radial cutting forces helps engineers design better tools. But how can we predict these forces accurately?

Through simulation, engineers can see how these forces behave. It’s like using a video game to test out a new level. By studying these factors, they can enhance performance and reduce waste. Isn’t it amazing how virtual worlds can help us in the real one?

This article explores the exciting world of milling cutter radial cutting forces simulation. Join us as we dive into this fascinating topic and discover what it means for engineers and manufacturers alike.

Milling Cutter Radial Cutting Forces Simulation Explained

Milling Cutter Radial Cutting Forces Simulation

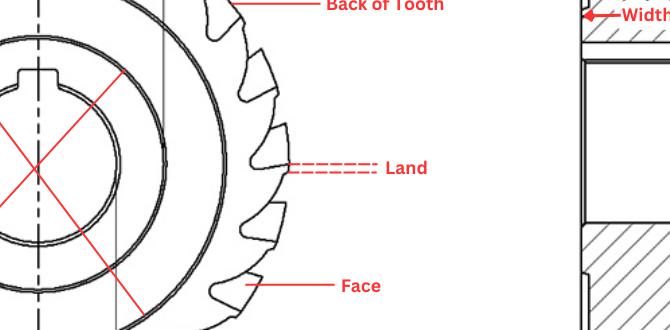

Milling cutter radial cutting forces simulation helps us understand how forces work during cutting. Imagine trying to slice through a tough cake; the harder you push, the more force you need. This simulation shows how different cutter shapes affect the cutting process. It also informs better tool design and enhances efficiency. By studying these forces, engineers can improve their machines, leading to safer and faster milling operations. Discovering these details makes the manufacturing world more exciting!Understanding Radial Cutting Forces

Definition of radial cutting forces in milling operations. Importance of radial forces in the machining process.Radial cutting forces occur during milling. They push against the direction of the cutter’s rotation. These forces are important. They affect how smoothly a machine cuts material. If the forces are too high, the cutter can break or the machine can stall. Understanding these forces helps create better milling processes. Here’s why they matter:

- Help predict cutter wear.

- Ensure product quality.

- Enhance machining efficiency.

What are the effects of radial cutting forces?

The effects can be significant. They can lead to increased wear on the cutter and affect the finish of the workpiece. Proper management of these forces is essential for successful machining.

Factors Influencing Radial Cutting Forces

Material properties of the workpiece and cutter. Cutting speed, feed rate, and depth of cut effects.Many factors change how tools cut materials. Material properties of both the cutter and the workpiece play a big role. Harder materials need more force. The cutting speed affects how smoothly the cutter works. Faster speeds can lead to more heat. The feed rate, or how fast the cutter moves, also matters. Higher rates mean more force is needed. Lastly, how deep the cutter goes changes the cutting forces too. Overall, all these factors shape how effective the milling cutter is.

How do material properties affect cutting forces?

Material properties influence how hard or easy it is to cut. Hard materials create more resistance, meaning more cutting force is needed.

Key Factors:

- Harder materials resist cutting.

- Soft materials cut easier.

- Quality of the cutter affects performance.

Case Studies in Radial Cutting Force Simulation

Realworld examples demonstrating simulation outcomes. Lessons learned from previous simulations.Real-world studies show how important simulations are for understanding radial cutting forces. For example, one project examined how different cutting speeds affected resistance. Results helped engineers choose better speeds and improved tool life. Another study focused on cutting angles, revealing that tiny changes can make a big difference in force. These lessons highlight the value of simulations. It’s like finding out that adding a pinch of salt can change the taste of your cookies!

| Case Study | Key Findings |

|---|---|

| Cutting Speeds | Better speeds lead to longer tool life. |

| Cutting Angles | Small changes in angle change forces significantly. |

Applications of Radial Cutting Force Simulation

How industries utilize simulations for process optimization. Case examples from aerospace, automotive, and manufacturing.Many industries rely on radial cutting force simulations to improve their processes. These tools help find the best ways to cut materials. For example, in the aerospace industry, they design parts that are lighter and stronger. In the automotive field, simulations help create safer and more efficient cars. Lastly, manufacturing uses them to reduce waste and save money. Here are some key benefits:

- Improved part design

- Better material use

- Faster production times

How do simulations save costs?

They reduce trial and error, saving time and money. Simulations allow businesses to test ideas digitally before making physical changes.

Future Trends in Cutting Force Simulation

Emerging technologies in simulation and modeling. Predictions for the future of milling cutter force analysis.New tools and methods are popping up every day in the world of cutting force simulation. Technologies like virtual reality and artificial intelligence are changing the game. Imagine running simulations that feel like a video game! Experts predict that in the future, milling cutter force analysis will be quicker and more accurate. You might not have to worry about your cuts being off; robots might do it for you! Keep an eye out for the next big breakthrough!

| Technology | Impact |

|---|---|

| Virtual Reality | Makes simulations more interactive |

| AI Algorithms | Boosts prediction accuracy |

| Big Data | Improves decision-making |

Best Practices for Simulating Radial Cutting Forces

Recommended guidelines for accurate simulation results. Common pitfalls to avoid during simulation setup.To get the best results from your milling cutter radial cutting forces simulation, follow these guidelines. Use the right tools and settings. Accurate measurements matter. Avoid common mistakes like incorrect material properties or tool setup. Pay attention to these key points:

- Choose the correct simulation software.

- Adjust cutting speed and feed rate accurately.

- Double-check your inputs before running the simulation.

With these tips, you can improve your chances of getting accurate results and success in your simulation work.

What are common mistakes in simulation setup?

Common mistakes include using wrong tool parameters or not calibrating the software properly. Always ensure the material properties match real conditions.

Conclusion

In summary, milling cutter radial cutting forces simulation helps us understand how tools work while cutting materials. You can see how different angles and speeds affect the process. By practicing simulations, we can improve our cutting techniques. So, explore these tools further and consider trying a simulation yourself to enhance your skills and knowledge in machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Cutter Radial Cutting Forces Simulation:Sure! When we use a milling cutter, it cuts materials like metal or wood. Radial cutting forces are the pushes and pulls against the cutter. We can simulate, or try to copy, how these forces act. This helps us learn how to make better cuts and avoid problems. Understanding these forces makes our work easier and safer!

Sure! Just give me the question, and I’ll answer it for you.

What Factors Influence The Magnitude Of Radial Cutting Forces Experienced By A Milling Cutter During Machining Operations?When we use a milling cutter to shape metal, several things can change how hard it cuts. The shape and sharpness of the cutter matter a lot. How fast we move the cutter and how deep it goes also influence cutting forces. If the cutter is too big for the job, it can struggle more. Finally, the type of metal we are cutting can make a big difference, too.

How Can Computer-Aided Simulation Techniques Be Utilized To Predict The Radial Cutting Forces In Milling Processes?We can use computer simulations to help us understand how cutting happens in milling. When we make a part, cutting forces push sideways, and these are called radial cutting forces. By using special software, we can create a virtual model of the milling process. This allows us to see and measure forces without actually cutting anything. It’s like a video game where we can test and learn before trying it in real life!

In What Ways Do Different Tool Geometries And Materials Affect The Radial Cutting Forces During Milling?Different tool shapes and materials change how hard it is to cut while milling. For example, a sharp tool cuts easier than a dull one. A tool made from strong metal can handle more pressure. If the tool has a special shape, it might grab the material better, leading to less force. So, choosing the right tool helps make cutting smoother and easier.

How Can The Results Of Radial Cutting Force Simulations Be Validated Against Experimental Data In Milling Applications?To check if our computer simulations of cutting forces are right, we compare them to real-life tests we do. First, we measure the cutting force while milling a piece of metal. Then, we see if our simulation results match those measurements. If they are close, it means our simulation is accurate. This helps us trust our results when planning for actual milling jobs.

What Role Do Cutting Parameters (Such As Feed Rate, Spindle Speed, And Depth Of Cut) Play In The Variation Of Radial Cutting Forces In Milling Simulations?Cutting parameters are special settings that affect how machines cut materials. The feed rate tells the machine how fast to move. Spindle speed controls how fast the cutting tool spins. Depth of cut shows how deep the machine cuts into the material. All these factors change the strength of the forces pushing against the cutting tool. If we adjust these settings, we can make cutting easier or harder.