Imagine a world where every cut made in metal glides perfectly. This magic is brought to life by milling cutters, the heroes of manufacturing. But did you know that tiny adjustments can make a huge difference? That’s where milling cutter radial relief optimization comes in. It helps our tools cut smoother and last longer.

Think about your favorite toy. It works best when all parts fit just right. Milling cutters need that same careful touch. When we optimize their radial relief, we improve how they slice through materials. This means less wear and tear and more efficiency.

Here’s a fun fact: even small changes to the shape of a milling cutter can double its lifespan! Isn’t that amazing? So, why is radial relief such a big deal? Let’s dive in and discover how this simple tweak can change the game in the world of machining. Are you ready?

Milling Cutter Radial Relief Optimization Techniques Explained

Milling Cutter Radial Relief Optimization

Have you ever wondered how to make cutting tools last longer? Milling cutter radial relief optimization helps solve this problem. It tailors the angle and shape of the cutter’s edges. This reduces wear during use, increasing efficiency and saving money. A well-optimized cutter cuts smoother and faster. Think of it like sharpening a pencil to write better. With the right adjustments, you can achieve better performance and results. Isn’t that an exciting way to improve machining processes?What is Radial Relief?

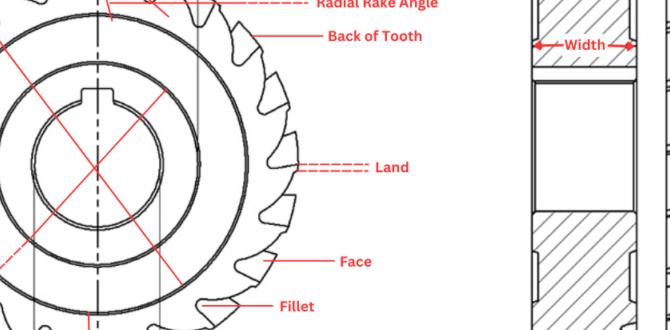

Definition and explanation of radial relief. How radial relief affects cutting performance.Radial relief refers to the sloped edges of a milling cutter’s teeth. This shape helps the cutter do its job better. It allows the tool to slice through materials more easily and smoothly. Without proper radial relief, cutting can feel like trying to slice butter with a rusty spoon—frustrating, right?

The angle of the relief helps reduce friction and heat, improving cutting performance. A well-designed cutter cuts faster, saves energy, and lasts longer. Think of it as giving your cutter a fresh pair of shoes for a sprint—much more efficient!

| Aspect | Effect |

|---|---|

| Low Radial Relief | High friction, faster wear |

| Optimal Radial Relief | Better cut, longer life |

Importance of Optimization in Milling Cutters

Benefits of optimizing radial relief for tool life. Impact of optimization on machining efficiency.Optimizing milling cutters is like giving them a spa day. It helps improve their health and extends their tool life. With better radial relief, tools wear down less and cut smoother. This means more time making chips and less time in the shop! Efficiency skyrockets, too, with less energy needed for the job. Imagine finishing two tasks in the time it takes to finish one. Sounds like a dream, right?

| Benefit | Impact |

|---|---|

| Increased Tool Life | Longer cutting time and fewer replacements |

| Enhanced Efficiency | Faster machining processes and reduced energy use |

With the right optimization, your milling cutter can be a superhero! It saves time and money while making sure those cuts are neat and clean.

Methods for Optimizing Radial Relief

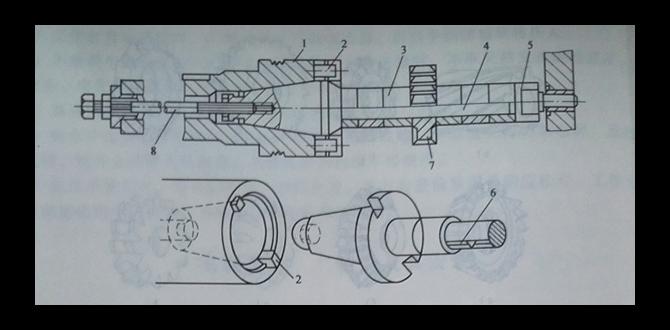

Traditional techniques for achieving optimal relief angles. Advanced computational methods and simulations used in optimization.To make milling cutters work better, you can use traditional and advanced methods. Traditional techniques involve setting the right relief angles by hand. This takes time and practice but can yield good results. Advanced methods rely on computers to simulate different designs. These simulations can find the best angles quickly. Using both methods helps create the most effective cutting tool.

What are some traditional techniques for optimal relief angles?

Common methods include manual adjustment, careful inspection, and trial testing. These practices focus on getting the angles just right for better cutting performance.

What are advanced computational methods used in optimization?

These methods include:

- 3D modeling for design accuracy

- Finite element analysis to predict performance

- Simulation software to test different relief angles

These tools help find the best settings quickly and accurately.

Factors Influencing Radial Relief Design

Material considerations for milling cutters. Influence of cutting parameters on radial relief requirements.Many things affect the design of milling cutters. One big factor is the material used. Different materials will wear differently. Another factor is cutting parameters. These include speed and feed rate. If you change these, you may need different radial relief. Here are some key points to remember:

- Material hardness impacts how sharp the cutter remains.

- Speed can change heat build-up, affecting cutter performance.

- Feed rate affects how much material is removed at once.

Keeping these factors in mind helps create better milling cutters. This way, they stay effective and last longer.

What are the key material considerations for milling cutters?

The material should be hard and durable. Also, consider how it reacts to heat when cutting. This ensures efficiency and cutting life.

How do cutting parameters influence radial relief needs?

High speeds and feed rates increase the tool’s stress. This usually means you need more radial relief to prevent damage.

Case Studies and Industry Applications

Realworld examples of radial relief optimization in manufacturing. Results and improvements noted in case studies.Many manufacturers have seen great success with radial relief optimization. For example, one study focused on a company producing precision gears. After adjusting their milling cutters, they cut production time by 30%! That means they could go home early—who doesn’t love an early Friday?

Another case involved a toolmaker who faced rapid wear on cutters. By optimizing the radial relief, they increased tool life by double! Now that’s what we call a win-win situation.

| Case Study | Improvement | Result |

|---|---|---|

| Precision Gears | Production Time | Reduced by 30% |

| Toolmaker | Tool Life | Doubled |

These examples show how a little tweak can lead to big wins in manufacturing! Remember, sometimes the smallest changes make the largest impacts.

Challenges in Radial Relief Optimization

Common pitfalls in the optimization process. Solutions to overcome challenges related to cutter performance.Many people face problems with milling cutter radial relief optimization. Here are some common pitfalls:

- Incorrect cutter angles can lead to poor performance.

- Ignoring tool wear affects cutting efficiency.

- Not testing in different materials may limit effectiveness.

To improve cutter performance, consider these solutions:

- Regularly check and adjust cutter angles.

- Use quality materials that reduce wear.

- Conduct tests with various materials for better results.

These steps can help overcome challenges in the optimization process, ensuring better outcomes.

What should I avoid in radial relief optimization?

Avoid incorrect angles, overlooking tool wear, and not testing on different materials.

Future Trends in Milling Cutter Optimization

Innovations in materials and designs for milling cutters. The role of automation and AI in future optimization strategies.New ideas in milling cutter design are changing how we work. Lightweight materials and special coatings make tools stronger and last longer. Also, computers are helping us. Automation and AI can analyze how cutters work and suggest improvements. This means better cuts and less waste. Expect exciting developments soon!

What innovations are shaping the future of milling cutters?

Lightweight materials and advanced designs are key trends. New coatings improve cutter strength, while automation and AI make optimization easier.

- Advanced materials for durability

- AI-driven analysis for smarter choices

- Eco-friendly products for less waste

Conclusion

In summary, optimizing radial relief on milling cutters improves cutting efficiency and tool life. You can enhance your machining processes by understanding this concept. Always consider the cutter’s design and how it affects performance. Experiment with different settings and observe the results. Keep learning about milling techniques to refine your skills and boost productivity. Happy cutting!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Radial Relief Optimization:Sure! When we talk about milling cutter radial relief optimization, we want to make the cutting tool better. That means we change its shape so it cuts more smoothly. We look at how the cutter touches the material, helping it work faster and last longer. By doing this right, we can save time and money while making good results.

Sure! Please provide me with the question you want me to answer, and I’ll make sure to keep it simple and clear for you.

What Is The Importance Of Radial Relief Angles In Defining The Performance And Efficiency Of Milling Cutters?Radial relief angles are important because they help milling cutters work better. These angles let the cutter remove metal smoothly without getting stuck. If the angle is just right, the cutter lasts longer and saves energy. This means you can make better parts and work faster. So, the right angles help everything run smoothly!

How Does Optimizing The Radial Relief Affect The Cutting Forces And Tool Wear During Milling Operations?When we optimize the radial relief, we change the shape of the tool’s edge. This helps the tool cut easier and with less force. Less force means less pushing or pulling, which can help the tool last longer. If the tool lasts longer, we reduce how often we need to replace it. Overall, better cutting means smoother work and fewer broken tools!

What Are The Common Methods Used To Evaluate The Effectiveness Of Radial Relief Optimization On Milling Cutters?To see if radial relief optimization works well on milling cutters, we can use several methods. First, we can check how much the cutter cuts materials and how fast it does that. Next, we look at how long the cutter lasts before it needs to be replaced. Finally, we can compare the smoothness of the cut surfaces. By using these methods, we can tell if the changes are helpful.

How Can Advanced Simulation Techniques Improve The Design And Optimization Of Radial Relief In Milling Cutters?Advanced simulation techniques help us create better milling cutters by letting us test designs on computers. We can see how the cutter will work before making it. This means we can change shapes and features easily to make them work best. By finding the best design, we save time and materials while making strong, efficient cutters. So, we end up with cutting tools that work better for us!

What Role Do Material Properties And Cutting Conditions Play In Determining The Optimal Radial Relief For Specific Milling Applications?Material properties and cutting conditions are very important for milling, which is when we cut shapes into metal or wood. Different materials, like soft plastic or hard steel, require different tools. The way we cut, like how fast or slow we go, also matters. If the tool has the right angle (called radial relief), it helps cut better and lasts longer. So, we need to think about both the material and how we’re cutting it to choose the best tool.