Have you ever wondered how fast a milling cutter should spin? Knowing the right speed can make a big difference in your projects. A milling cutter RPM calculator chart can help you find the perfect speed. It might sound complex, but it’s not!

Imagine trying to cut wood with a dull knife. It takes forever, right? Now, think about using a sharp knife. It works better and faster! The same idea applies to milling cutters. They need the right speed to cut well. Too fast or too slow can ruin your material or break your tool.

In this article, we will explore how you can use a milling cutter RPM calculator chart. You’ll learn how to pick the right speed for your projects. Ready to cut like a pro? Let’s dive in!

Milling Cutter Rpm Calculator Chart: Optimize Your Machining Processes

Milling Cutter RPM Calculator Chart

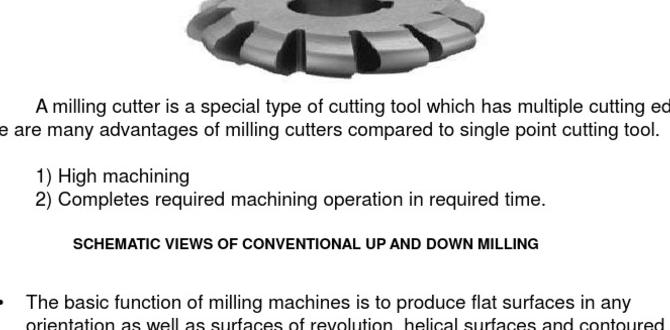

Understanding how to use a milling cutter RPM calculator chart can greatly improve your machining projects. This handy tool helps you find the right rotational speed for different materials and cutter types. Did you know that running a cutter too fast can cause damage? Conversely, going too slow may lead to inefficiency. By applying the right RPM, you enhance both safety and performance. Use this chart to ensure you’re always on the right track for successful milling!Understanding Milling Cutter Basics

Definition of milling cutters and their types. Importance of RPM in milling processes.Milling cutters are tools used in machines to shape materials like metal or wood. There are different types of milling cutters, including end mills and face mills. Each type works best for specific tasks. Knowing the right RPM is vital for these tools. It helps the cutter spin at the best speed to cut smoothly. If the RPM is too high or too low, it can damage the cutter or the material.

What are the types of milling cutters?

Milling cutters come in various styles. Here are a few:

- End Mills: Great for making slots

- Face Mills: Perfect for flat surfaces

- Ball Nose Mills: Ideal for curved surfaces

Why is RPM important in milling?

Choosing the correct RPM helps you make the best cuts. Too fast can create heat and wear. Too slow can lead to rough cuts. Thus, understanding RPM keeps your tools and materials safe.

Factors Affecting RPM Selection

Material type and hardness. Cutter diameter and number of flutes. Machine capabilities.Several factors play a role in choosing the right RPM for cutting. First, the type and hardness of the material matter. Softer materials require lower RPMs, while harder items may need higher speeds. Second, the cutter’s diameter and number of flutes also influence RPM. Larger diameters often need slower speeds. Finally, the machine’s capabilities can limit or enhance RPM selection. Understanding these factors helps ensure effective cutting and better work quality.

What factors affect RPM selection?

Key factors include material type, cutter diameter, number of flutes, and machine capabilities.

Factors to Consider:

- Material Type: Harder materials need higher RPM.

- Cutter Diameter: Larger cutters require slower speeds.

- Number of Flutes: More flutes can affect speed choices.

- Machine Capabilities: Know your machine’s limits.

How to Use the RPM Calculator

Stepbystep guide to inputting data. Examples of common calculations.Using the RPM calculator is easy and fun! First, you need to gather some key details. You’ll want to input the material type, cutter diameter, and feed rate. This will help you get the correct calculations. Here’s a quick example. If the cutter diameter is 2 inches and the desired speed is 100 feet per minute, the calculator will do the magic for you!

| Cutter Diameter (inches) | Speed (feet per minute) | RPM |

|---|---|---|

| 1 | 100 | 1592 |

| 2 | 100 | 796 |

| 3 | 100 | 530 |

Now for some fun: If only calculating calories were this easy, right? So, jump into the calculator and let it do the heavy lifting while you enjoy a snack!

Milling Cutter RPM Chart: Quick Reference

Display of RPM values for different materials. Recommended RPM adjustments based on cutter specifications.Need to know how fast to spin your milling cutter? Look no further! This handy chart shows RPM values for various materials. Each material needs a different speed for the best results. You will also find tips on adjusting RPM based on the cutter’s specs. Remember, spinning it too fast can turn your tool into a frisbee!

| Material | Recommended RPM |

|---|---|

| Aluminum | 8000 – 12000 |

| Steel | 2500 – 4000 |

| Wood | 6000 – 12000 |

Adjust the speed as needed. For example, smaller cutters may need a higher RPM while larger ones may not. Following the chart means less guesswork and more fun in the shop!

Common Mistakes in RPM Calculation

Misunderstanding material properties. Ignoring machine limitations.Calculating the right RPM can feel like a math puzzle. One common mistake is not understanding material properties. Different materials need different speeds. Using the wrong RPM can lead to a worse finish or even break your cutter! Another issue is ignoring machine limitations. Every machine has its own capabilities. If you push too hard, you might end up with a stuck blade and a headache instead of a neat cut. Remember, it’s better to be safe than sorry!

| Material | Recommended RPM |

|---|---|

| Aluminum | 3000-6000 |

| Wood | 8000-12000 |

| Steel | 1000-2000 |

Enhancing Performance with Optimal RPM Values

Benefits of using the correct RPM. Case studies of improved results.Using the right RPM can greatly boost performance in milling. Correct RPM leads to:

- Better surface finish

- Longer tool life

- Higher cutting speeds

For example, a factory reduced tool wear by 30% after adjusting their RPM to optimal levels. Another case showed a 20% faster production rate with the accurate settings. These results prove that knowing the correct RPM matters.

Why is the correct RPM important?

The correct RPM ensures smooth cuts and minimizes damage to tools.

Additional Resources for Milling Professionals

Recommended tools and software for RPM calculations. Links to forums and communities for milling advice.For milling professionals, the right tools can make a big difference. Here are some useful resources:

- Milling RPM Calculator Software: Programs like G-Wizard help find the best cutting speeds.

- Forums and Communities: Check out sites like Practical Machinist for advice and tips from experts.

- Webinars and Tutorials: YouTube has many videos explaining RPM calculations and machine setups.

These resources connect you with great information to improve your milling skills.

What tools can help with milling calculations?

Helpful tools include calculators and software designed for RPM and feed rate. You can easily find them online. Remember, using the right tools helps you work smarter!

Future Trends in Milling Technology

Advancements in cutter design and materials. The impact of automation and smart technology on RPM calculations.New wheels are turning in milling technology! Cutting tools are getting a makeover with sharper designs and advanced materials. This means they last longer and cut better. Picture a superhero cutter flying through metal! Plus, smart technology is joining the party. Automation helps machines determine the best RPM without breaking a sweat. It’s like having a calculator that never gets tired!

| Feature | Advancement |

|---|---|

| Cutter Design | Enhanced shapes for faster cutting |

| Materials | Stronger, lightweight substances |

| Automation | Smart tools calculate optimal RPM |

In the future, expect cutting tools to become even smarter. It’s not just cutting; it’s cutting-edge! Who knew metalworking could be so exciting?

Conclusion

In summary, a milling cutter RPM calculator chart helps you find the right speed for your projects. It ensures you cut materials efficiently and safely. By knowing the right RPM, you improve your work quality and tool life. Explore more about cutting speeds and try using a chart on your next project for better results!FAQs

What Is The Formula For Calculating The Optimal Rpm For Different Types Of Milling Cutters?To find the best speed for milling cutters, you can use a simple formula. First, you’ll need the cutter’s diameter in inches. Then, you multiply that by the speed in feet per minute (or FPM). Finally, divide that number by 3.82. This gives you the optimal rotations per minute, or RPM, for your cutter.

How Do Material Properties Affect The Rpm Settings For Milling Cutters In Machining Operations?The material of the cutting tool and the material you’re working on both matter. Hard materials, like metal, need slower speeds. This helps the cutter last longer and work better. Softer materials, like wood, can go faster. So, you adjust the RPM, or revolutions per minute, to fit what you’re cutting.

What Is The Significance Of Chip Load In Relation To The Rpm Of A Milling Cutter?Chip load tells us how much material the cutter removes with each turn. When RPM (revolutions per minute) goes up, chip load needs to match it. If RPM is too high and chip load is too low, the cutter can break. If the chip load is too high, the cutter gets stuck. Finding the right balance helps the cutting tool work well and last longer.

How Can I Use A Milling Cutter Rpm Calculator To Improve Machining Efficiency And Tool Life?You can use a milling cutter RPM (revolutions per minute) calculator to find the best speed for cutting metal. This helps you make clean cuts and reduces wear on your tools. By using the right speed, you save time and avoid mistakes. Remember to check the calculator before starting to make your work easier and your tools last longer!

Are There Specific Rpm Recommendations For Using Different Materials, Such As Aluminum, Steel, Or Titanium, With Milling Cutters?Yes, there are specific recommendations for how fast to spin your milling cutter when working with different materials. For aluminum, you can use a higher speed, around 10,000 RPM (revolutions per minute). For steel, a lower speed of about 2,000 to 4,000 RPM is best. For titanium, you should go even slower, around 1,000 to 2,000 RPM. Always check the cutter’s instructions to get the best results!