Have you ever wondered why some machines cut materials smoothly while others struggle? The secret often lies in the milling cutter’s runout and its concentricity. These two terms are key to understanding how well a milling cutter performs.

Imagine trying to draw a picture with a shaky pencil. Your lines would be wobbly, right? This is similar to what happens when there is runout in a milling cutter. When the cutter wobbles, it creates uneven cuts. On the other hand, concentricity refers to how well the cutter’s edges line up with its center. If they don’t match up, it can also lead to problems.

Did you know that even small differences in runout can affect the final product? This means understanding these concepts isn’t just for experts; it’s vital for anyone who works with machines. So, let’s dive deeper into how milling cutter runout and concentricity work together. You may be surprised at what you discover!

Milling Cutter Runout vs Concentricity

Milling cutter runout and concentricity are key concepts in machining. Runout describes how much a cutter wiggles during rotation, which can affect the quality of the cut. Concentricity measures how well the edges of the cutter align with the center. Both factors influence the final product’s precision and smoothness. Did you know that even tiny errors can lead to big problems? Understanding these terms helps in achieving better machining results. Accuracy matters!

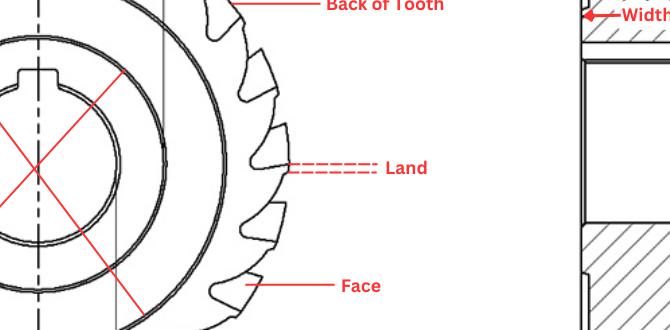

Defining Runout in Milling Cutters

Explanation of runout and its measurement. Impact of runout on machining accuracy.

Runout in milling cutters is like a dance party where not all dancers are in sync! It measures how much the cutter wobbles as it spins. If it wobbles too much, it can cause trouble. To measure runout, we check how far from the center the cutter edge moves. A small runout means better machining accuracy. Too much runout can create rough edges and uneven surfaces, which nobody wants! So, it’s like making sure everyone is on the beat for a great performance!

| Measurement | Impact on Accuracy |

|---|---|

| Runout checks how much a cutter moves off-center. | High runout leads to rough cuts and errors. |

| A smaller runout equals a smoother finish. | Too much wobble? Say goodbye to precision! |

So, keep that cutter centered and dance on successfully!

Understanding Concentricity in Milling Cutters

Definition and significance of concentricity. How concentricity is measured in milling operations.

Concentricity shows how evenly a milling cutter spins around its center. It is key for smooth cuts and better finished products. High concentricity means less wobbling, which prevents errors. To measure concentricity in milling, special tools check how close the cutting edge spins to the centerline. Here are important methods:

- Dial indicator tests.

- Laser measurement tools.

- Runout checks for accuracy.

What is the importance of concentricity in milling?

Concentricity is crucial for making precise cuts. High quality and accurate parts depend on it. Less wobbling leads to longer tool life and better finishes.

Comparative Analysis of Runout and Concentricity

Key differences between runout and concentricity. How runout affects concentricity and vice versa.

Runout and concentricity have key differences. Runout shows if a tool spins evenly. If a milling cutter wobbles, it has high runout. Concentricity measures how well a part aligns around a center point. High runout can cause low concentricity. Likewise, poor concentricity may increase runout. They affect each other. Understanding both helps improve machining quality.

What is the difference between runout and concentricity?

Runout refers to how much a tool moves away from a perfect circle, while concentricity is how well parts center around one axis.

Key points are:

- Runout checks smooth spinning.

- Concentricity checks proper alignment.

Common Causes of Runout in Milling Cutters

Factors contributing to runout in milling operations. Preventive measures to minimize runout.

Milling cutters can have a bad day, just like us! Runout happens when the cutter isn’t spinning straight. This can be caused by factors like improper installation, worn bearings, or even dirt on the spindle. Regular checks on these areas can help keep things running smooth. To prevent runout, always ensure that cutters are properly secured and clean. Trust me, a happy cutter means happy cuts!

| Common Causes | Preventive Measures |

|---|---|

| Improper installation | Secure the cutter tightly |

| Worn bearings | Regularly check and replace them |

| Dirt on spindle | Keep it clean and tidy |

Improving Concentricity in Milling Processes

Techniques for enhancing concentricity. Tools and setups that promote better concentricity.

To boost concentricity in milling, first, check your tools. Use high-quality cutting tools that fit perfectly. A snug fit means less wiggle. Next, keep everything clean. Dirt and chips can mess up your setup like a cat on a keyboard! Also, try using a precision chuck. This will hold the cutter tight and straight, making less runout. Finally, always double-check your setups—like making sure your shoelaces are tied before running! They might trip you up otherwise.

| Technique | Benefit |

|---|---|

| High-Quality Cutting Tools | Reduced wiggle and better cuts |

| Precision Chuck | Improved tool stability |

| Routine Setup Checks | Fewer mistakes while milling |

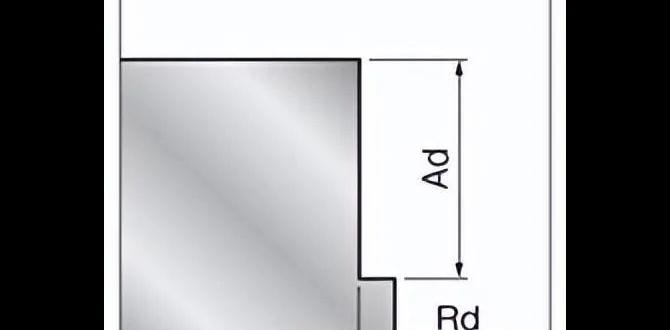

Effects of Runout and Concentricity on Machining Quality

Relationship between runout, concentricity, and surface finish. Case studies demonstrating the impact on final products.

Runout and concentricity are crucial for machining quality. Runout refers to how much a tool wobbles during operation. This wobble can harm the final surface of a part. On the other hand, concentricity measures how well parts fit together. If runout is high, the surface finish can be rough. Studies show that even a small deviation can affect parts significantly. For example:

- Tool A had a runout of 0.02 mm, resulting in a smooth finish.

- Tool B had a runout of 0.1 mm, leading to noticeable surface imperfections.

These examples highlight the importance of maintaining both runout and concentricity for high-quality machining.

What is the impact of runout on product quality?

Runout affects the accuracy and finish of machined parts. A higher runout can lead to poor fit. This means parts may not work well together.

Industry Standards and Guidelines

Relevant standards governing milling cutter performance. Recommendations for maintaining acceptable levels of runout and concentricity.

To ensure quality in milling, certain standards guide performance. These standards help keep the tools accurate. A popular standard is ISO 1302, which focuses on measuring runout and concentricity. Following guidelines can help reduce errors.

- Check tools often for wear.

- Use proper clamping techniques.

- Keep machines clean and well-lubricated.

These practices maintain good performance and product quality.

What are the key standards for milling cutter performance?

Common standards include ISO 1302 and ANSI B5.48. These provide rules to manage runout and concentricity effectively.

Recommendations for Improving Performance:

- Regularly calibrate machines.

- Monitor tool speed and feed rates.

Using these standards can lead to better cuts and satisfied customers.

Conclusion

In summary, milling cutter runout and concentricity are important for precision. Runout refers to how wobbly the cutter spins. Concentricity ensures the cutter’s edge aligns perfectly with the center. Both affect the quality of your work. To improve your skills, check your tools often. You can read more about proper tool care to enhance your machining projects!

FAQs

What Is The Difference Between Milling Cutter Runout And Concentricity, And How Do They Affect Machining Accuracy?

Milling cutter runout means the tool wobbles a bit when it spins. Concentricity is about how well the tool lines up with the part you’re cutting. If the cutter has lots of runout, it can make cuts less smooth. If it’s not concentric, it can create uneven shapes. Both issues can ruin the accuracy of your work.

How Can Excessive Runout In A Milling Cutter Lead To Defects In Machined Parts?

Excessive runout means the milling cutter wobbles too much as it spins. This can cause it to cut unevenly. If the cutter isn’t steady, the part you are making may have bumps or uneven edges. This makes the part not fit or work right. It’s important to keep the cutter straight to make good parts.

What Are The Common Methods Used To Measure Runout And Concentricity In Milling Cutters?

To measure runout and concentricity in milling cutters, we can use different tools. One common method is a dial indicator, which shows tiny movements. You place it against the cutter to see if it wobbles. Another way is to use a micrometer to check how even the cutter’s parts are. These tools help make sure the cutter works well when we use it.

How Do Tolerances For Runout And Concentricity Differ Among Various Types Of Milling Operations?

Runout and concentricity are about how straight and round things are. In milling, which is a way to cut shapes out of materials, each type has its own rules for these tolerances. For example, when we do a simple cut, we might be okay with more wiggle. But for detailed parts, we need them to be very precise. So, tighter tolerances mean less room for mistakes.

What Steps Can Be Taken To Minimize Runout And Improve Concentricity When Setting Up A Milling Cutter?

To make sure your milling cutter works well, first, check if it’s clean and free from dirt. Next, you can use a good measuring tool to see if it’s straight. Tighten it firmly in the machine so it doesn’t move around. Finally, spin the cutter slowly to watch for any wobbles. This helps keep everything centered, so your work will be neat and smooth.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Difference Between Milling Cutter Runout And Concentricity, And How Do They Affect Machining Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Milling cutter runout means the tool wobbles a bit when it spins. Concentricity is about how well the tool lines up with the part you’re cutting. If the cutter has lots of runout, it can make cuts less smooth. If it’s not concentric, it can create uneven shapes. Both issues can ruin the accuracy of your work.”}},{“@type”: “Question”,”name”: “How Can Excessive Runout In A Milling Cutter Lead To Defects In Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Excessive runout means the milling cutter wobbles too much as it spins. This can cause it to cut unevenly. If the cutter isn’t steady, the part you are making may have bumps or uneven edges. This makes the part not fit or work right. It’s important to keep the cutter straight to make good parts.”}},{“@type”: “Question”,”name”: “What Are The Common Methods Used To Measure Runout And Concentricity In Milling Cutters? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure runout and concentricity in milling cutters, we can use different tools. One common method is a dial indicator, which shows tiny movements. You place it against the cutter to see if it wobbles. Another way is to use a micrometer to check how even the cutter’s parts are. These tools help make sure the cutter works well when we use it.”}},{“@type”: “Question”,”name”: “How Do Tolerances For Runout And Concentricity Differ Among Various Types Of Milling Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Runout and concentricity are about how straight and round things are. In milling, which is a way to cut shapes out of materials, each type has its own rules for these tolerances. For example, when we do a simple cut, we might be okay with more wiggle. But for detailed parts, we need them to be very precise. So, tighter tolerances mean less room for mistakes.”}},{“@type”: “Question”,”name”: “What Steps Can Be Taken To Minimize Runout And Improve Concentricity When Setting Up A Milling Cutter? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your milling cutter works well, first, check if it’s clean and free from dirt. Next, you can use a good measuring tool to see if it’s straight. Tighten it firmly in the machine so it doesn’t move around. Finally, spin the cutter slowly to watch for any wobbles. This helps keep everything centered, so your work will be neat and smooth.”}}]}