Have you ever wondered how to use a milling cutter safely? Understanding milling cutter safety and handling protocols is vital for anyone working in a workshop. Accidents can happen in the blink of an eye, but knowing the right steps can protect you.

Imagine you’re working on an exciting project, and you have a sharp milling cutter right in front of you. It’s powerful and can make precise cuts. But without proper handling, it could also cause serious injuries. Every year, many people face injuries while using these tools.

What if I told you that following simple safety rules can help you stay safe? Here’s a fun fact: well-trained workers are less likely to get hurt, even in busy environments. Knowing the basic safety measures boosts confidence and keeps everyone out of harm’s way.

Join us as we explore essential milling cutter safety and handling protocol. Together, we can ensure your next project is not just successful but safe too!

Milling Cutter Safety And Handling Protocol: Essential Guidelines

Milling Cutter Safety and Handling Protocol

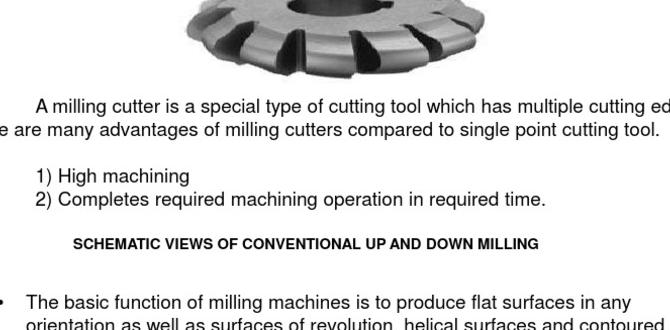

Milling cutter safety is crucial for anyone working with machines. First, always wear protective gear, like goggles and gloves. Did you know that most accidents occur because people forget this step? Additionally, keep the workspace tidy. A clean area reduces accidents! Remember, when handling tools, always have a firm grip and use both hands if possible. Following these basic protocols can make your work safer and more enjoyable. Stay safe and smart while milling!Understanding Milling Cutters

Types of milling cutters and their specific applications. Importance of selecting the right cutter for safety.Milling cutters come in various types, each with specific tasks. Some common types include:

- End Mill: Used for cutting flat surfaces.

- Face Mill: Great for facing large surfaces.

- Ball Nose Mill: Perfect for curved shapes.

- Drill Mill: Functions as both a drill and a mill.

Selecting the right cutter is crucial for safety. Using the wrong type can cause accidents. Always match the cutter to the task. This keeps you safe while working.

Why is it important to select the right milling cutter?

Selecting the right milling cutter ensures safety and efficiency in your projects. Using the wrong cutter can cause tool breakage or injuries, making this choice extremely important.

Personal Protective Equipment (PPE)

Necessary PPE for milling operations. Guidelines for proper PPE usage and maintenance.Milling can be a fun task, but safety gear is a must! Workers should wear the right personal protective equipment (PPE). This includes goggles, ear protection, gloves, and steel-toed boots. These items help keep you safe from flying bits and loud noises. Always check your gear before starting. Think of it like a superhero suit: it helps you work safer and look cool! Remember, no one likes a boring safety talk, but wearing the right PPE is like having your own safety sidekick.

| PPE Item | Purpose |

|---|---|

| Goggles | Protects eyes from debris. |

| Ear Protection | Reduces noise exposure. |

| Gloves | Protects hands from cuts. |

| Steel-Toed Boots | Prevents foot injuries. |

Using PPE isn’t just a rule; it’s a smart choice. Keep your gear clean and stored correctly. A little care can make your PPE last longer, just like your favorite toys! Remember, safety first so you can keep milling without a hitch!

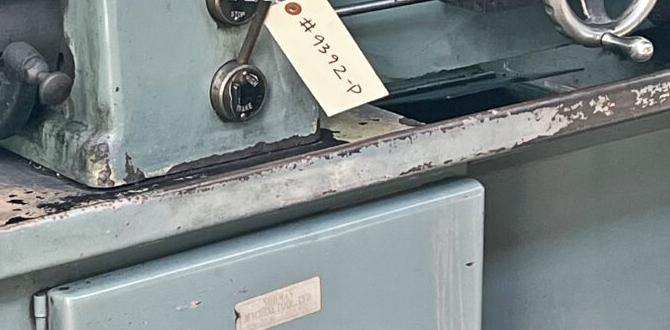

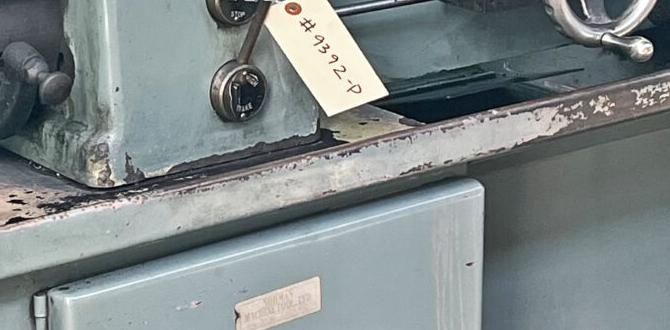

Pre-Operation Checks

Essential checks before using milling cutters. Tools and equipment inspection protocols.Before you dive into using a milling cutter, it’s important to check a few things first. Think of it like looking both ways before you cross the street—safety first! Make sure your tools are in good shape. Are there any chips or cracks? Give them a good look!

Here’s a handy checklist:

| Item | Check |

|---|---|

| Milling Cutter | Inspect for damage |

| Work Area | Clear and organized |

| Personal Safety Gear | Worn and secure |

Always wear your safety goggles—they’re not just for show! This simple routine helps keep you safe and can save you from a trip to the emergency room. Remember, a little prep can go a long way!

Safe Handling Practices

Techniques for properly handling milling cutters. Training requirements for operators.Properly handling milling cutters is crucial for safety. Always wear protective gear like gloves, goggles, and ear protection. Using the right grip ensures you don’t become an accidental juggler with sharp objects! Operators should undergo proper training to understand risks and safe practices. Remember, “A sharp tool in a safe hand is a happy tool!”

| Safe Handling Techniques | Training Requirements |

|---|---|

| Use both hands for control. | Complete a safety training program. |

| Keep area clean and organized. | Learn emergency procedures. |

| Check tool for damage before use. | Hands-on practice under supervision. |

Following these practices helps in reducing accidents. After all, safety is no laughing matter, unless you count the giggles from knowing you’re using tools the right way!

Machine Setup and Adjustments

Steps to safely set up milling machines. Importance of securing workpieces effectively.Setting up a milling machine safely takes careful steps. First, always wear proper safety gear like goggles and gloves. Next, check the machine for any damage. It’s important to secure your workpiece tightly before starting. Unsecured pieces can cause accidents. Use clamps or vises to hold them firmly. Here’s a quick checklist for setup:

- Check machine parts.

- Wear safety gear.

- Inspect workpieces.

- Secure with clamps.

Taking these actions keeps everyone safe during milling. Remember, safety first leads to better work quality!

Why is securing workpieces important?

Securing workpieces prevents movement and accidents. Loose pieces can fly out or cause the tool to jam, leading to injuries.

Emergency Procedures

Actions to take in case of accidents or incidents. First aid measures for injuries associated with milling operations.If an accident happens while using a milling cutter, stay calm! First, check if someone is hurt. If there are injuries, call for help right away. Even true heroes need a hand sometimes. For minor cuts, rinse the area with water. Cover it with a clean bandage. For bigger accidents, apply pressure to stop bleeding and keep the injured area still. Stay with them until help arrives.

| Injury Type | First Aid Measure |

|---|---|

| Minor Cuts | Wash and bandage |

| Serious Cuts | Apply pressure, keep still |

| Fainting | Lay down, raise feet |

Remember, the best way to handle emergencies is staying prepared! Stay safe, and you’ll be a milling superstar!

Maintenance and Storage

Best practices for maintaining milling cutters. Proper storage methods to ensure cutter longevity and safety.Keeping milling cutters happy is key to their performance. Regular cleaning helps remove dust and chips. Use a soft brush or cloth; no need for a hardcore scrub! For maintenance, check for wear—dull cutters can lead to mistakes. Also, store them in a dry place. Using a labeled container keeps them safe and sound. Remember, a good home for your cutters prevents accidents and lasts longer. So, treat them like the stars they are!

| Best Maintenance Practices | Storage Tips |

|---|---|

| Clean after every use | Use a labeled container |

| Inspect for wear regularly | Store in a dry, dust-free area |

| Sharpen as needed | Avoid stacking them |

Training and Awareness Programs

Importance of ongoing training for staff. Topics to cover in safety training sessions.Training keeps workers safe and aware of the hazards in the workplace. Regular sessions help everyone understand the right ways to handle milling cutters. Key topics to cover in safety training include:

- Personal protective equipment (PPE) use

- Proper milling cutter handling techniques

- Emergency procedures

- Machine operation safety

This ongoing training builds confidence and helps prevent accidents. Remember, knowledge is power in keeping people safe!

Why is safety training important?

Firms with regular safety training see 50% fewer accidents. This protection benefits everyone!

Conclusion

In conclusion, milling cutter safety is crucial for everyone. Always wear protective gear, like goggles and gloves. Keep your workspace clean and organized. Never remove guards while the machine is running. By following these handling protocols, you can stay safe while working. We encourage you to read more about milling tools and practice these safety tips. Stay safe and informed!FAQs

What Personal Protective Equipment (Ppe) Should Be Worn When Operating A Milling Cutter To Ensure Safety?When using a milling cutter, you should wear safety goggles to protect your eyes. Earplugs can help guard your ears from loud noise. It’s also important to wear gloves to keep your hands safe. Lastly, wear a mask to avoid breathing in dust or small particles. These items help keep you safe while working.

What Are The Main Safety Precautions To Take Before Starting A Milling Cutter To Prevent Accidents?Before starting a milling cutter, we need to follow some safety steps. First, check that the machine is clean and free of any tools. Then, wear safety goggles to protect your eyes. Make sure to tie back long hair and remove loose clothing. Finally, always keep your hands away from the cutter while it’s moving.

How Should Milling Cutters Be Properly Stored And Maintained To Ensure Safe Handling?You should store milling cutters in a dry place to avoid rust. Keep them in a special case or box to protect them. Always handle them carefully to prevent cuts. Clean them after each use with a cloth. Check for damage before using them again.

What Emergency Procedures Should Be In Place For Incidents Involving A Milling Cutter?If something goes wrong with a milling cutter, we should act quickly. First, turn off the machine right away. Next, check if anyone is hurt and call for help if needed. Always keep a first aid kit nearby. Finally, tell an adult or supervisor about what happened.

What Training Or Qualifications Are Necessary For Operators To Safely Handle And Use Milling Cutters?To safely use milling cutters, you need some training. First, you should learn how the machine works. You also need to know about safety rules. Practice is important too, so you can use the cutter well. Finally, it helps to have a small license or certificate to show you’re ready.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Personal Protective Equipment (Ppe) Should Be Worn When Operating A Milling Cutter To Ensure Safety? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a milling cutter, you should wear safety goggles to protect your eyes. Earplugs can help guard your ears from loud noise. It’s also important to wear gloves to keep your hands safe. Lastly, wear a mask to avoid breathing in dust or small particles. These items help keep you safe while working.”}},{“@type”: “Question”,”name”: “What Are The Main Safety Precautions To Take Before Starting A Milling Cutter To Prevent Accidents? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before starting a milling cutter, we need to follow some safety steps. First, check that the machine is clean and free of any tools. Then, wear safety goggles to protect your eyes. Make sure to tie back long hair and remove loose clothing. Finally, always keep your hands away from the cutter while it’s moving.”}},{“@type”: “Question”,”name”: “How Should Milling Cutters Be Properly Stored And Maintained To Ensure Safe Handling? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should store milling cutters in a dry place to avoid rust. Keep them in a special case or box to protect them. Always handle them carefully to prevent cuts. Clean them after each use with a cloth. Check for damage before using them again.”}},{“@type”: “Question”,”name”: “What Emergency Procedures Should Be In Place For Incidents Involving A Milling Cutter? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If something goes wrong with a milling cutter, we should act quickly. First, turn off the machine right away. Next, check if anyone is hurt and call for help if needed. Always keep a first aid kit nearby. Finally, tell an adult or supervisor about what happened.”}},{“@type”: “Question”,”name”: “What Training Or Qualifications Are Necessary For Operators To Safely Handle And Use Milling Cutters? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely use milling cutters, you need some training. First, you should learn how the machine works. You also need to know about safety rules. Practice is important too, so you can use the cutter well. Finally, it helps to have a small license or certificate to show you’re ready.”}}]}