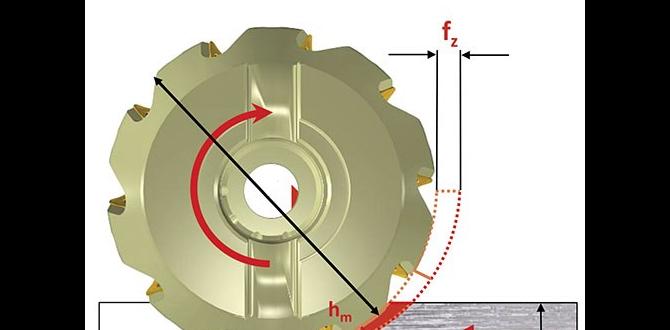

Have you ever wondered how a milling cutter really works? These tools play a key role in shaping materials. They create smooth surfaces and precise cuts. But what happens at the cutting edge? That’s where the fun begins!

Imagine trying to slice a loaf of bread with a dull knife. It’s tough, right? The same idea applies here. A milling cutter’s secondary cutting edge is crucial. It helps perform better and last longer. But why should we focus on this? Understanding the secondary cutting edge can reveal secrets to improved performance.

Did you know that even a tiny change can make a big difference? Analyzing these edges can lead to better designs and more efficient machines. It’s not just about cutting; it’s about making the best cuts possible. Join us as we dive into the fascinating world of milling cutter secondary cutting edge analysis!

Milling Cutter Secondary Cutting Edge Analysis Explained

Understanding milling cutter secondary cutting edges is crucial for precise machining. These edges help improve cutting performance and surface quality. By analyzing them, engineers can identify wear patterns, allowing for better tool maintenance and longer tool life. Have you ever noticed how some tools last longer than others? This insight sheds light on that mystery. A well-maintained milling cutter not only cuts faster but also saves money over time. Engaging with this analysis can result in big savings and efficiency in production.

Understanding Milling Cutters

Definition and purpose of milling cutters in machining.. Types of milling cutters and their applications..

Milling cutters are tools used to shape materials like metal and wood. Their main job is to remove material from a workpiece, creating the desired shape. There are several types of milling cutters, including:

- **End Mill** – Great for making deep cuts.

- **Face Mill** – Ideal for smooth surfaces.

- **Ball Nose Cutter** – Perfect for curves and 3D shapes.

- **Slab Mill** – Used for large flat surfaces.

Each cutter has special uses in different projects. Knowing which milling cutter to choose makes work easier and more precise.

What are milling cutters used for?

Milling cutters shape materials like metal and wood by removing material to create specific designs.

Importance of Secondary Cutting Edges

Role of secondary cutting edges in enhancing cutting efficiency.. Impact on surface finish and tool life..

Secondary cutting edges play a vital role in cutting tasks. They help make cutting more efficient, allowing tools to work better. This means less time and energy are wasted.

Using these edges can greatly improve the surface finish. A clean and smooth surface makes a big difference. Tools also last longer when secondary edges are used effectively.

- Enhance cutting efficiency: Secondary edges make the cutting process faster and smoother.

- Impact on surface finish: They create cleaner cuts, giving a better look.

- Increase tool life: Tools with secondary edges last longer, saving money.

What do secondary cutting edges do?

Secondary cutting edges help improve cutting efficiency, surface finish, and tool life. These benefits make the whole process smoother and more effective.

Geometrical Aspects of Secondary Cutting Edges

Analysis of edge angles and their effects on cutting action.. Effects of edge radius on chip formation and tool wear..

When looking at secondary cutting edges, angle matters! The sharpness of these edges can really change cutting action. Different edge angles help tools bite into materials or glide smoothly. Plus, the edge radius affects how chips form during cutting. A larger radius can mean more tool wear—like wearing down a shoe on a rocky path!

| Edge Angle | Effect on Cutting | Edge Radius | Impact on Chips |

|---|---|---|---|

| Acute | Better penetration | Small | Sharp chips |

| Obtuse | Smoother cutting | Large | Chunky chips |

In short, having the right edge can help in cutting efficiency! It’s all about finding that sweet spot to keep tools sharp and ready for action.

Wear Mechanisms on Secondary Cutting Edges

Types of wear (abrasive, adhesive, etc.) affecting secondary edges.. Factors influencing wear rates during milling operations..

When cutting tools are in action, wear and tear is inevitable. Secondary cutting edges can experience different types of wear, like abrasive and adhesive. Abrasive wear happens when hard particles scratch the edge, like a cat on a scratching post! On the other hand, adhesive wear occurs when materials stick together and tear apart. Several factors influence how quickly wear happens, including speed, feed rate, and the material being cut. Keep your tools sharp to minimize the fun of wear! Here’s a quick summary:

| Type of Wear | Description |

|---|---|

| Abrasive | Caused by hard particles scratching the edge. |

| Adhesive | Occurs when materials stick and tear apart. |

Techniques for Analyzing Cutting Edge Performance

Methodologies for assessing the effectiveness of secondary cutting edges.. Use of advanced imaging and measurement technologies in analysis..

Analyzing the performance of secondary cutting edges is essential in milling. Different techniques help ensure they work effectively. Here are a few methodologies:

- Visual Inspection: This method checks for visible wear and tear on edges.

- Microscopic Analysis: Using high-powered microscopes reveals fine details and flaws.

- Laser Scanning: Advanced lasers measure edge geometry with precision.

- Wear Testing: Simulated cutting shows how edges hold up under pressure.

These techniques help improve tools, making work easier and more efficient for everyone involved.

What are some effective methods to assess cutting edge performance?

Effective methods include visual inspection, microscopic analysis, laser scanning, and wear testing. Each method plays a vital role in understanding how well the cutting edges perform.

Optimizing Milling Cutter Design for Secondary Edges

Design considerations for improving secondary cutting edge efficiency.. Examples of innovative designs that enhance performance..

Milling cutter design can be improved by focusing on secondary cutting edges. These edges help cut materials more effectively. Here are some important design ideas:

- Use special coatings to reduce friction.

- Shape edges to enhance durability.

- Adjust angles for better cutting precision.

Innovative designs, like rounded edges or spiral configurations, can boost performance. Studies show that a new cutter shape can increase cutting speed by 30%. This change not only saves time but also makes the job easier.

What are design considerations for milling cutters?

Focusing on edges is key. Improving their shape can make cutting smoother and faster.

Some examples of advanced designs include:

- Multi-tooth cutters for quicker results.

- Variable pitch cutters for better stability.

Real-World Applications and Case Studies

Industryspecific examples demonstrating the importance of secondary edges.. Case studies highlighting improvements in operations through edge analysis..

Many industries benefit greatly from using secondary cutting edges. These edges improve tool life and performance. For instance, in the automotive sector, companies saw 20% more efficient cuts. This led to less time in production. In aerospace, firms reported fewer errors in machining parts. They enjoyed smoother surfaces and better fits.

- In manufacturing, edge analysis reduced waste by 15%.

- Construction equipment showed 30% longer tool life.

These examples show that understanding secondary edges can lead to great improvements.

How does edge analysis impact manufacturing?

Edge analysis helps manufacturers save time and reduce waste. By examining secondary edges, they can fine-tune their processes and make better tools.

Future Trends in Milling Cutter Technology

Innovations in materials and coatings for enhanced performance.. Advancements in design and technology influencing secondary edge optimization..

New materials and coatings will make milling cutters even better. These innovations can make cuts smoother and last longer. Strong coatings help reduce wear and tear. Design improvements will also play a key role. Engineers are focusing on optimizing secondary edges for perfect performance. This means cutters will not only work well but also save time and money.

- Advanced coatings like ceramic and diamond.

- Lightweight yet strong materials.

- Smart designs that allow better chip removal.

What are the benefits of new milling cutter technology?

New tech improves speed and accuracy. This saves time and reduces costs. Better materials also keep tools from wearing out quickly. This means less downtime for repairs!

How does design affect milling cutter performance?

Smart designs help in chip removal. A better shape means more efficient cutting. This makes tasks easier and faster for everyone.

Conclusion

In conclusion, analyzing the secondary cutting edge of milling cutters helps improve machining efficiency. You can better understand how these tools work by exploring their angles and shapes. This knowledge can lead to better cuts and longer tool life. We encourage you to read more about milling techniques and try applying these insights in your own projects!

FAQs

What Are The Primary Functions Of Secondary Cutting Edges In Milling Cutters, And How Do They Contribute To Overall Cutting Performance?

Secondary cutting edges on milling cutters help to make the cutting smoother and more efficient. They assist in removing extra bits of material from the workpiece. This means your project can have cleaner and more precise shapes. By working together with the main edges, they help the cutter last longer and perform better.

How Does The Geometry Of Secondary Cutting Edges Affect Chip Formation And Material Removal Rates During Milling Operations?

The shape of the secondary cutting edges helps decide how the tool cuts into the material. When these edges are sharp and well-shaped, they make chips easier to form. This means the tool can remove material faster. If the edges are dull or not shaped well, it can slow down the process. So, good edges help us work better and quicker!

What Methods Or Tools Can Be Used To Analyze The Wear Characteristics Of Secondary Cutting Edges In Milling Cutters?

To check how milling cutters wear down, we can use a few tools. First, we can look at them under a microscope to see tiny details. We can also measure the cutting edges with special tools to find out how much they have changed. Sometimes, we use pictures taken with cameras to see how they look over time. These methods help us understand how to make the cutters last longer.

How Does The Selection Of Material For Milling Cutters Influence The Effectiveness And Durability Of Secondary Cutting Edges?

The choice of material for milling cutters affects how well they work and how long they last. Strong materials help the cutter stay sharp longer and cut better. If we use a softer material, the edges may wear out quickly. A good material also helps avoid breaking. So, picking the right material is very important for the cutter’s success.

In What Ways Can The Optimization Of Secondary Cutting Edges Lead To Improved Surface Finish And Dimensional Accuracy In Machined Components?

When we make the edges of cutting tools better, they work more smoothly. This means they can cut through materials without leaving rough spots. A smooth cut makes the surface of the piece look nicer. It also helps the piece fit better with other parts because it is cut more exactly. So, better edges lead to cleaner cuts and pieces that are the right size.