Milling cutters play an important role in making profile cuts. Imagine trying to carve a unique shape from wood or metal. The right milling cutter can make all the difference. Did you know there are many types of milling cutters? Each one has its special job. Choosing the right one can save time and avoid mistakes. Have you ever wondered how professionals pick the best milling cutter for their projects? Let’s explore milling cutter selection and learn what makes each type unique for profile cuts. This knowledge can help everyone from amateurs to experts. Get ready to dive into the world of milling!

Milling Cutter Selection For Profile Cuts: A Complete Guide

Milling Cutter Selection for Profile Cuts

Choosing the right milling cutter for profile cuts can shape your project’s success. The cutter’s size, shape, and material all matter. Have you ever wondered why some cuts look cleaner? The answer often lies in selecting the right tool. A high-speed steel cutter works well for softer materials, while carbide cutters handle tougher jobs better. Remember, the right choice can save time and enhance the quality of your work. Why not explore what works best for your next project?Understanding Profile Cuts

Definition and significance of profile cuts in machining.. Common applications and industries that utilize profile cuts..Profile cuts are special shapes made in materials during machining. They are important because they help create unique designs and fit parts together perfectly. Many places use profile cuts, like car factories, furniture shops, and any industry that makes custom pieces. Imagine a cookie cutter; it shapes the dough into fun forms. Profile cuts do the same but for metal, wood, and plastic!

| Industry | Common Applications |

|---|---|

| Automotive | Creating parts like frames and panels |

| Woodworking | Shaping furniture and cabinetry |

| Aerospace | Landing gear and engine components |

| Electronics | Custom circuit board layouts |

By understanding how profile cuts work, industries can make better products faster. In fact, using profile cuts can improve efficiency by up to 30% in some cases! That’s more time for snacks!

Factors to Consider in Milling Cutter Selection

Material compatibility and its impact on cutter performance.. Geometry and design considerations for specific profile cuts..Selecting the right milling cutter for your profile cuts is like choosing the best pizza topping; it really matters! First, think about material compatibility. The cutter must match the material you’re working with to perform well. For instance, steel needs a different cutter than aluminum. Next, consider the geometry and design. The shape of your cutter determines how well it slices and dices. Using the wrong design can lead to a messy outcome—kind of like putting pineapple on pizza!

| Material Type | Recommended Cutter Material |

|---|---|

| Steel | High-Speed Steel (HSS) |

| Aluminum | Carbide |

| Plastic | Solid Carbide |

Cutting Parameters and Their Influence

Important cutting parameters such as feed rate, speed, and depth of cut.. How cutting parameters affect the selection of milling cutters..Cutting parameters are key players in milling. They guide your cutter like a GPS! The main factors are feed rate, speed, and depth of cut. The feed rate determines how quickly the cutter moves through the material. Speed is how fast the cutter spins. The depth of cut tells you how deep the cutter goes into the material. Choosing the right settings can turn a tough job into a smooth ride. Misplaced settings? You might end up creating more shavings than actual cuts!

| Parameter | Importance | Result |

|---|---|---|

| Feed Rate | Controls material removal | Faster cuts, smooth finish |

| Speed | Affects cutter life | Too fast? Dull cutters! |

| Depth of Cut | Defines the workload | Too deep? Could cause breakage! |

Tool Material and Coatings

Common materials used for milling cutters (e.g., HSS, carbide, cermet).. The role of coatings in enhancing cutter performance and lifespan..Choosing the right material for milling cutters is like selecting the best ice cream flavor—there are many tasty options! Common materials include High-Speed Steel (HSS), which is tough and great for most tasks, and carbide, known for its hardness and durability. Cermet is another choice, blending carbide and ceramic for sharp cuts. Adding coatings? That’s like putting sprinkles on your sundae! They lift performance and lengthen life, making sure your cutter stays sharp longer.

| Material | Characteristics |

|---|---|

| HSS | Strong and versatile |

| Carbide | Harder and lasts longer |

| Cermet | Sharp with great wear resistance |

Best Practices for Milling Cutter Maintenance

Techniques for maintaining milling cutters to ensure optimal performance.. Signs of wear and when to replace milling cutters..Taking care of milling cutters is essential for good results in profile cuts. Regularly check your cutters for signs of wear. Look for damaged edges or dullness. Here are some tips for maintenance:

- Clean the cutters after each use to remove debris.

- Sharpen them regularly for best performance.

- Store them properly to avoid damage.

Replace milling cutters if they no longer perform well. This will save time and improve the quality of your work.

How do I know when to replace milling cutters?

Watch for dull edges, unusual noises, or poor cutting quality. These are signs it’s time for a new cutter.

Case Studies: Successful Profile Cutting Applications

Examples of effective milling cutter selection in realworld scenarios.. Analysis of outcomes and lessons learned from these case studies..Real-world examples show how the right milling cutter can ensure success in profile cutting. Here are a few cases:

- A furniture factory

- An auto part manufacturer

- A custom sign maker

Lessons learned include choosing the right cutter can boost quality and save time. This careful selection brings satisfaction to both makers and buyers.

Why is milling cutter selection important?

Understanding the right milling cutter choice leads to better results. Choosing the correct tool means quicker work and finer details.

Key benefits:

- Improved quality of cuts.

- Reduced production time.

- Cost efficiency.

Future Trends in Milling Cutter Technology

Innovations in milling cutter design and materials.. The impact of technology advancements on profile cutting efficiency and precision..New ideas in milling cutter design are shaping the future. Advanced materials are making tools stronger and more durable. This means they last longer and cut better. Technology is also improving how machines work. With better programming, cutting jobs are faster and more precise. This helps industries save time and money. Smart tools can even adjust themselves! Here are some trends:

- Lightweight materials reduce wear.

- Smart technology improves accuracy.

- 3D printing makes custom tools.

These changes mean profile cuts can achieve new heights!

What innovations are shaping milling cutter technology?

Innovations include new materials, smart technology, and 3D printing. These advancements help tools cut faster and last longer, improving overall efficiency.

Conclusion

In summary, choosing the right milling cutter for profile cuts is crucial. Consider material, cutter shape, and size for the best results. Remember to match the cutter to your project needs for efficiency and quality. You can experiment with different cutters and learn more about their features. Keep exploring and practicing to improve your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Selection For Profile Cuts:Sure! When you choose a milling cutter for profile cuts, think about what material you are cutting. Different materials need different types of cutters. You should also consider the size of the cut you want to make. Lastly, check the speed of your machine. All these things help you pick the best cutter for your work!

Sure! Please ask your question, and I’ll be happy to help!

What Factors Should Be Considered When Selecting A Milling Cutter For Profile Cuts In Different Materials?When you choose a milling cutter for profile cuts, think about the material you are cutting. Some cutters work better on soft materials, like wood, while others are better for hard materials, like metal. You should also look at the shape of the cutter; different shapes make different cuts. Lastly, consider the size of the cutter for the job you need to do.

How Do The Geometry And Design Of A Milling Cutter Affect The Quality Of The Profile Cut Produced?The shape and design of a milling cutter are really important for making good cuts. If the cutter’s edges are sharp and shaped correctly, it can slice through material smoothly. This helps create clean and sharp edges on the piece we are cutting. If the cutter is dull or not shaped well, it can make rough cuts, which don’t look nice. So, to get the best results, we need a good cutter!

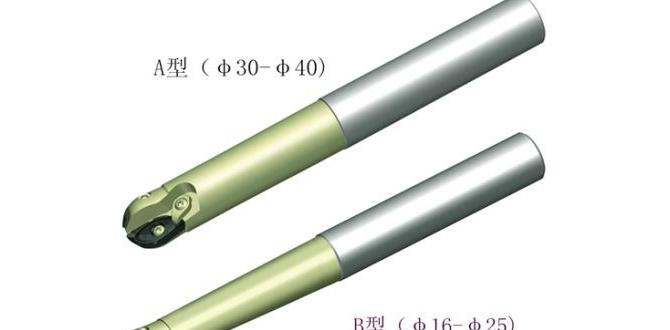

What Are The Advantages Of Using Specialized Milling Cutters, Such As Ball-Nose Or Tapered Cutters, For Intricate Profile Cuts?Using special milling cutters like ball-nose or tapered cutters helps us make detailed and curved shapes. They can reach tight corners and make smooth edges. This means our designs look better and fit together nicely. Also, they help us cut faster and save time. With these tools, we can create amazing, precise shapes easily!

How Does Cutter Diameter Influence The Feed Rate And Speed Settings For Achieving Optimal Results In Profile Milling?The cutter diameter is how wide the cutting tool is. A larger cutter cuts more material at once. This means you can go faster, so you use a higher speed setting. If the cutter is smaller, you go slower to avoid mistakes. Always remember, the right size helps you get the best results!

What Role Do Cutting Tool Coatings And Materials Play In The Performance And Durability Of Milling Cutters Used For Profile Applications?Cutting tool coatings and materials help milling cutters work better and last longer. The right coating makes it tough against wear and heat. This means the cutter can cut through different materials without breaking down quickly. When we use strong materials, the cutter stays sharp, so we get good results in our work. In short, good coatings and materials make our tools more powerful and durable.