Have you ever wondered how machines create such precise shapes and designs? One secret lies in something called a milling cutter. This special tool helps shape materials like metal and wood with amazing accuracy. It’s fascinating to see how different milling cutter shoulder milling examples can create everything from car parts to intricate designs.

Imagine a sculptor chipping away at a block of marble. Each cut must be exact for the statue to come to life. Milling cutters do the same but with machines doing the work. They use various shapes and sizes, making them perfect for many tasks.

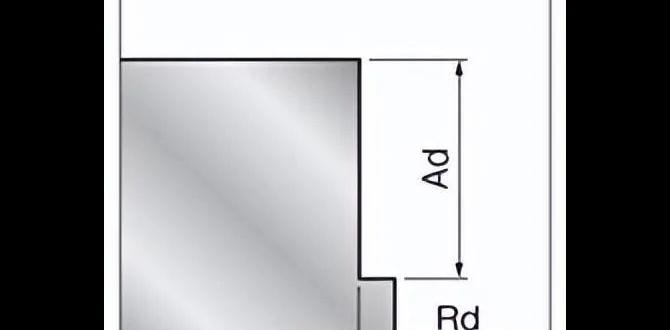

For instance, think about how a shoulder mill works. It has a flat top and can create a ledge or step in a piece of material. This ability is crucial in many industries! Have you ever seen a machine part that looks like it has steps or layers? A shoulder mill made that possible.

In this article, we’ll explore milling cutter shoulder milling examples. You will learn how these tools transform materials and bring ideas to life. Get ready to discover the magic of milling!

Milling Cutter Shoulder Milling Examples And Applications

Milling Cutter Shoulder Milling Examples

Shoulder milling cutters come in various shapes and sizes. They are perfect for creating edges and grooves in different materials. Imagine cutting a perfect slot into wood or metal. Isn’t that impressive? In shoulder milling, the cutter’s edge does the hard work. It produces smooth surfaces and can even create intricate designs. Did you know that these milling cutters also make it easier to machine angled surfaces? They are truly versatile tools for any workshop!Understanding Shoulder Milling

Definition of shoulder milling and its significance in machining.. Key components and tools involved in shoulder milling processes..Shoulder milling is a type of machining process. It creates flat surfaces and grooves. This technique is important because it helps shape materials accurately. Key tools include milling cutters and machines. These tools have specific designs that make the milling process easier and more efficient.

- Milling Cutter: Cuts the material.

- Machine: Moves the cutter and controls the process.

- Workpiece: The material being shaped.

What is shoulder milling used for?

Shoulder milling is used for making flat surfaces and grooves in materials like metal or wood. It’s great for creating parts in machines and products.

Applications of Shoulder Milling

Industries that benefit from shoulder milling techniques.. Specific examples of parts and components manufactured using shoulder milling..Shoulder milling plays a big role in many industries. For example, automotive companies use it to make engine parts like cylinder heads. In aerospace, it helps create brackets and frames that fly high. Even furniture makers benefit by crafting smooth edges on tables. Let’s not forget about medical devices; shoulder milling shapes precise tool components! Check out the key industries and examples below:

| Industry | Examples of Parts |

|---|---|

| Automotive | Cylinder Heads |

| Aerospace | Brackets |

| Furniture | Table Edges |

| Medical | Surgical Tools |

Shoulder milling really makes things work better and look cool too! Who knew cutting things could be so interesting?

Advantages of Shoulder Milling

Benefits of using shoulder milling over other milling methods.. Discussion on efficiency, precision, and tool life..Shoulder milling offers great benefits over other milling methods. It’s like the Swiss Army knife of cutting tools—versatile and efficient. First, it improves efficiency by removing more material in less time. Second, you get higher precision for those tricky cuts. Finally, the lifespan of tools is often longer, saving you money. Why replace your tools so often when shoulder milling can keep them sharper? Plus, who doesn’t want to be the hero of tool longevity?

| Aspect | Shoulder Milling | Other Methods |

|---|---|---|

| Efficiency | High | Variable |

| Precision | Superior | Okay |

| Tool Life | Longer | Shorter |

Choosing the Right Milling Cutter for Shoulder Milling

Factors to consider when selecting milling cutters for shoulder milling.. Recommendations for different materials and thicknesses..Choosing the right milling cutter can feel like picking a favorite ice cream flavor—there are so many options! First, consider the material you’ll be cutting. Different materials need different cutters to perform well. For example, tough steel needs solid carbide cutters. Also, think about thickness. Thicker materials often require a more robust cutter. Here’s a handy guide:

| Material | Recommended Cutter | Thickness |

|---|---|---|

| Aluminum | High-speed steel | Up to 0.5 inches |

| Steel | Carbide | 0.5 to 1 inch |

| Stainless Steel | Coated carbide | 1 inch and more |

Remember, the right cutter makes a big difference! You’ll cut faster, save time, and your parts will shine like a new penny.

Best Practices for Effective Shoulder Milling

Tips for optimal cutting parameters (speed, feed, depth).. Importance of proper tooling setup and maintenance..For effective shoulder milling, follow these tips: Use the right cutting speed, feed rate, and depth. Start with a high-speed rotation for faster cutting. Adjust the feed rate to ensure smooth progress without stalling. Keep the depth shallow to maintain control over the tool.

Also, proper tool setup is crucial. Regular maintenance keeps the milling cutter sharp and effective. Check the tools often to avoid dull blades, which can lead to poor results.

- Maintain the tool regularly.

- Adjust parameters based on material type.

- Monitor tool wear and replace when needed.

What are optimal cutting parameters for shoulder milling?

Optimal cutting parameters include high-speed rotation, a steady feed rate, and a shallow depth of cut. Adjust these factors based on the material for the best results.

Case Studies: Real-world Examples of Shoulder Milling

Detailed case studies demonstrating successful shoulder milling applications.. Analysis of the techniques used and results achieved in various industries..Shoulder milling has transformed many industries, showing its magic in real-world cases. For instance, the automotive sector often uses it for creating precise shapes in engine blocks. Skateboard manufacturers love shoulder milling for making smooth edges. These methods boost production speed and cut costs. In a recent study, a factory that used shoulder milling saw a 20% increase in efficiency. Who knew cutting could be this much fun?

| Industry | Application | Results |

|---|---|---|

| Automotive | Engine Blocks | Precision shapes and quicker production |

| Sports Equipment | Skateboards | Smooth edges and reduced costs |

Conclusion

In conclusion, shoulder milling cutters are essential tools in machining. They help create edges and grooves on various materials. You can see examples in manufacturing parts like brackets and plates. Understanding their use can improve your skills. We encourage you to explore more about milling techniques. Practicing with different cutters will enhance your learning and experience. Happy milling!FAQs

Sure, Here Are Five Related Questions On The Topic Of Milling Cutter Shoulder Milling:Sure! Here are some simple answers about milling cutter shoulder milling: 1. What is shoulder milling? Shoulder milling is cutting shapes on the side of a material. We use a special tool called a milling cutter. 2. How does a milling cutter work? A milling cutter spins really fast. It cuts the material by moving against it. 3. What materials can we use for shoulder milling? We can use metals, plastics, and wood. Each material has different types of cutting tools. 4. Why is shoulder milling important? Shoulder milling helps make parts of machines and products. It makes them strong and fits together well. 5. How do we stay safe while milling? We wear safety glasses and keep hands away from moving parts. Safety is very important!

Sure! Please ask your question, and I’ll be happy to help you with a simple answer.

What Are The Key Design Features Of Milling Cutters Specifically Used For Shoulder Milling Applications?Milling cutters for shoulder milling have special features. First, they have sharp edges to cut metal easily. They are also wide, which helps make flat surfaces. The shape of the cutter is important to reach corners well. Lastly, the cutter is usually made of strong materials so it lasts longer.

How Does The Choice Of Milling Cutter Geometry Affect The Efficiency And Surface Finish In Shoulder Milling Operations?The shape of the milling cutter affects how well it cuts and how smooth the surface is. If we choose a cutter with sharp edges, it can cut faster and make a nicer finish. A flat cutter may take longer but can work better on wide surfaces. By picking the right cutter shape, we help our machines work easier and create better-looking parts.

What Materials Are Typically Used For Manufacturing Milling Cutters Intended For Shoulder Milling, And Why Are They Preferred?Milling cutters for shoulder milling are often made from high-speed steel or carbide. High-speed steel is strong and can cut quickly. Carbide is even tougher and lasts longer. We prefer these materials because they can handle hard metals without breaking easily. This helps us make better cuts and finish our projects faster.

In What Industries Is Shoulder Milling Most Commonly Applied, And What Are The Typical Workpiece Materials Involved?Shoulder milling is often used in the manufacturing industry. We see it in car making, machine parts, and tool making. The workpieces are usually tough materials like metal and plastic. These materials help create strong and useful products.

What Cutting Parameters, Such As Speed And Feed Rate, Are Critical For Optimizing Performance In Shoulder Milling Processes?In shoulder milling, two important factors are speed and feed rate. Speed is how fast the cutting tool spins. Feed rate is how quickly the tool moves across the material. If you use the right speed and feed rate, you can make better cuts and finish your work faster. It helps your machine last longer too!