Have you ever wondered how milling cutters stay sharp and effective? These tools are vital in shaping materials for many industries. But did you know that stress relief heat treatment plays a big role in their performance? This process helps reduce stress in the steel, making the cutting edges more durable.

Imagine using a tool that breaks easily or wears out quickly. That can be frustrating! The right heat treatment can prevent such issues. It makes a milling cutter stronger and longer-lasting. This means it can cut through materials with ease.

Let’s explore why stress relief heat treatment is so important. You’ll learn how it improves milling cutters and why most manufacturers rely on it. When we dive deep into this topic, you’ll see just how much of a difference it makes in various settings.

Milling Cutter Stress Relief Heat Treatment Explained

Milling Cutter Stress Relief Heat Treatment

Milling cutter stress relief heat treatment helps improve tool life and performance. This process reduces internal stresses in the metal. Have you ever wondered why some tools last longer than others? It’s often due to careful heat treatment. After heat treatment, cutters can resist wear better and maintain sharpness. Picture a new toy that lasts longer because it’s well-made. The same idea applies here. This method not only enhances durability but also saves costs in the long run.Understanding Milling Cutters

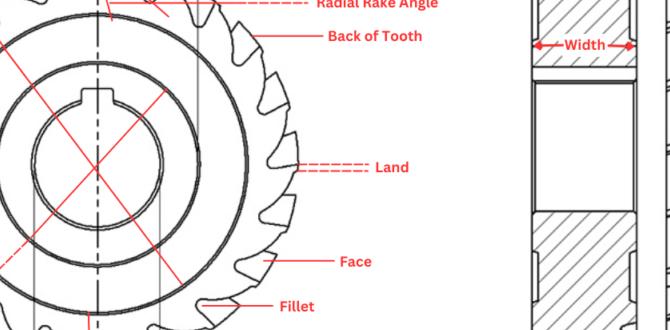

Definition and types of milling cutters. Importance of milling cutters in manufacturing processes.Milling cutters are special tools that help shape and cut materials in manufacturing. Think of them like fancy scissors, but for machines! There are many types, including end mills and face mills, each with their own unique jobs. These tools are crucial in making everything from car parts to toys. Without milling cutters, we’d be stuck cutting things with rocks—ouch! They help create smooth surfaces and precise shapes, making them heroes in the factory world.

| Type of Cutter | Description |

|---|---|

| End Mill | Used for vertical cutting. |

| Face Mill | Great for milling flat surfaces. |

| Ball Nose Mill | Perfect for curved shapes. |

The Need for Stress Relief in Milling Cutters

Explanation of stress factors in cutting tools. How stress affects performance and lifespan.Cutting tools face stress during use. This stress can come from heat, pressure, and vibration. Over time, these factors can change the tool’s shape, making it less effective. When a milling cutter is stressed, its performance drops. This leads to quicker wear and tear, reducing its lifespan. Milling cutter stress relief heat treatment helps fix these issues by easing the tension in the tool and improving its durability.

How does stress affect cutting tools?

Stress can lead to:

- Loss of sharpness

- Cracks and breaks

- Shortened tool life

Benefits of Heat Treatment for Milling Cutters

Improved hardness and wear resistance. Enhanced toughness and durability.Heat treatment works wonders for milling cutters. It boosts hardness and wear resistance, making them tougher than a two-dollar steak! This process strengthens the metal, which helps it slice through materials smoothly without wearing down too fast. Toughness and durability get a serious upgrade too. Imagine your milling cutter as a superhero, ready to face any challenge with a big grin! Better tools mean fewer breaks and more time for fun.

| Benefit | Description |

|---|---|

| Improved Hardness | Strong enough to tackle tough materials. |

| Enhanced Toughness | Durable and ready for heavy-duty jobs. |

Key Steps in the Heat Treatment Process

Pretreatment preparation and considerations. Detailed process of heating and cooling.Before starting heat treatment, get everything ready! Check the milling cutter for cleanliness and any cracks—like checking your snack to make sure it’s not stale! Heat treatment has two main parts: heating and cooling. First, heat the cutter slowly to the right temperature. This step makes it soft and ready for fixing flaws. Then, cool it down quickly, usually in oil or air. This process helps it regain strength. Remember, each step is important, like following a recipe for cookies that won’t burn!

| Step | Action | Purpose |

|---|---|---|

| Pretreatment | Clean and inspect | Ensure quality and readiness |

| Heating | Slow rise to temperature | Make material soft |

| Cooling | Rapid cooling | Restore strength |

Post-Heat Treatment Evaluations

Methods for assessing effectiveness of heat treatment. Tools and techniques for measuring stress relief.Evaluating heat treatment effectiveness is crucial. Different methods help us ensure that our milling cutters are stress-free and ready to work again. One common method is examining the material microstructure under a microscope. There are also tools like ultrasonic testing and X-ray diffraction that measure stress relief. By using these techniques, we can see how well the heat treatment performed. Remember, happy tools lead to happy cuts!

| Method | Tool/Technique | Purpose |

|---|---|---|

| Microstructure Evaluation | Microscope | Check material changes |

| Ultrasonic Testing | Ultrasonic Device | Measure stress levels |

| X-ray Diffraction | X-ray Machine | Assess internal stresses |

Common Heat Treatment Challenges

Potential issues during the heat treatment process. Strategies for overcoming these challenges.Heat treatment can be tricky. There are many challenges that can happen during the process. Some common problems include warping or cracking. These issues affect the quality of the milling cutter. To tackle these challenges, here are a few strategies:

- Control the heating speed carefully.

- Use the right cooling methods.

- Ensure precise temperature monitoring.

- Perform regular equipment checks.

Staying aware of these problems can help improve results and make the milling cutter last longer!

What are common issues in heat treatment?

Common issues include warping, cracking, and uneven heat distribution.

How can these challenges be overcome?

Improving heating speed, monitoring temperatures, and using proper cooling can help.

Best Practices for Implementing Heat Treatment

Recommendations for optimal heat treatment cycles. Tips for maintaining milling cutter quality posttreatment.Milling cutters deserve some TLC, especially during heat treatment. Start with your heat treatment cycles. They should be well-planned to balance strength and toughness. Always follow the ideal temperature ranges. It’s like cooking! Too hot and you burn it; too cold and it’s undercooked. After treatment, keep the quality high. Store them in a cool, dry place to prevent rust. Remember, a happy cutter makes for a happy shop!

| Heat Treatment Cycle | Recommended Temperature | Duration |

|---|---|---|

| Annealing | 1500°F | 2 hours |

| Quenching | 1800°F | 1 hour |

| Tempering | 400°F | 1 hour |

Case Studies: Successful Applications of Heat Treatment

Examples of industries benefiting from heattreated milling cutters. Testimonial insights from manufacturing professionals.Many industries rely on heat-treated milling cutters, and the results are impressive! For example, the automotive and aerospace sectors have seen huge benefits. These sectors report that heat treatment boosts tool life by up to 50%! That’s like getting free miles on your car, but for cutting tools! Manufacturing professionals rave about how these treated cutters provide better precision and reduce downtime. One engineer joked, “Using untreated cutters is like trying to cut butter with a spoon!”

| Industry | Benefits |

|---|---|

| Automotive | 50% longer tool life |

| Aerospace | Improved precision |

Future Trends in Milling Cutter Treatment Technologies

Innovations in heat treatment processes. The impact of emerging technologies on milling cutter efficiency.Innovations in heat treatment processes are changing milling cutter technology. New techniques help make these cutters stronger and last longer. For instance, cryogenic treatment cools tools to very low temperatures. This reduces stress and increases durability.

Emerging technologies such as artificial intelligence help improve cutter efficiency. AI can predict wear patterns and suggest the best treatments. This means better performance and cost savings.

- Advanced heating methods enhance hardness.

- Smart analytics guide treatment choices.

- Faster cooling leads to improved strength.

How will future technologies impact milling cutters?

Future technologies will lead to stronger, more efficient milling cutters. They will last longer and perform better, which saves time and money for manufacturers.

Conclusion

In conclusion, milling cutter stress relief heat treatment is important for strong tools. This process helps reduce internal stresses, making cutters last longer. By understanding this, you can choose better tools for your projects. Don’t forget to explore more about heat treatment techniques for improved performance. Happy cutting, and keep learning to enhance your skills!FAQs

Sure! Here Are Five Questions Related To Milling Cutter Stress Relief Heat Treatment:Milling cutters are tools we use to cut metal. Sometimes, when we make them, they get stressed. To fix this, we use something called heat treatment. This means we heat them up and then cool them down slowly. This process makes the cutters stronger and helps them last longer.

Sure! Please give me the question you want me to answer.

What Is The Purpose Of Stress Relief Heat Treatment In The Manufacturing Of Milling Cutters?Stress relief heat treatment is a way to make milling cutters stronger. When they are made, the metal can have hidden stress, which might cause them to break. This heat treatment helps to release that stress. After it, the cutters become more reliable and last longer when we use them. So, it helps us make better tools for cutting.

How Does The Stress Relief Heat Treatment Process Affect The Hardness And Wear Resistance Of Milling Cutters?The stress relief heat treatment process helps milling cutters become tougher. When we heat and cool them, it reduces tiny internal problems. This makes the cutters harder, so they can last longer. They also resist wear better, meaning they won’t get damaged easily when cutting. Overall, this process helps our tools work well for a long time.

What Are The Typical Temperature Ranges And Durations Used In The Stress Relief Heat Treatment Of Milling Cutters?For stress relief heat treatment of milling cutters, we usually heat them to about 1000 to 1200 degrees Fahrenheit. This process helps to reduce any stress in the metal. We keep them at this temperature for about one to two hours. After that, we let them cool down slowly. This makes the milling cutters stronger and helps them last longer.

How Can Improper Stress Relief Heat Treatment Impact The Performance And Lifespan Of Milling Cutters During Machining Operations?Improper heat treatment can make milling cutters weak. When we don’t relieve stress correctly, the cutters can crack or break easily. This means they won’t cut well and could wear out faster. If you want tools that last, it’s important to treat them properly. Otherwise, you may need to replace them often, which costs more money.

What Are The Differences Between Stress Relief Heat Treatment And Other Heat Treatments, Such As Annealing Or Tempering, Specifically For Milling Cutters?Stress relief heat treatment helps to relax stress in metal parts like milling cutters. It makes the metal less likely to break or change shape during use. Annealing makes metal softer and easier to shape, while tempering makes it tougher after hardening. Each heat treatment has a different goal, but stress relief focuses on reducing stress, not changing the metal’s softness or hardness.