Have you ever wondered how machines cut metal with such precision? One of the key tools in this process is the milling cutter. These tools spin rapidly to shape materials like wood and metal. But what if you could see how they work in real time? That’s where thermal imaging comes in.

Imagine a scene where a milling cutter slices through a piece of steel. You might see sparks flying, but what if you could also see the heat? Thermal imaging setups allow us to do just that. They capture images of heat patterns, showing us where the cutter is working hardest. This technology can help improve efficiency and safety in factories.

It’s fascinating to think that we can use heat to understand tools better. Many people don’t realize that seeing heat can change how we use machines. Have you ever thought about what goes on during cutting? The answers might surprise you.

By exploring milling cutter thermal imaging setups, we open a new world of understanding. This tool not only helps improve performance but can also make our work safer and smarter. Let’s dive in and learn about this amazing technology!

Milling Cutter Thermal Imaging Setup: Optimizing Efficiency

Milling Cutter Thermal Imaging Setup

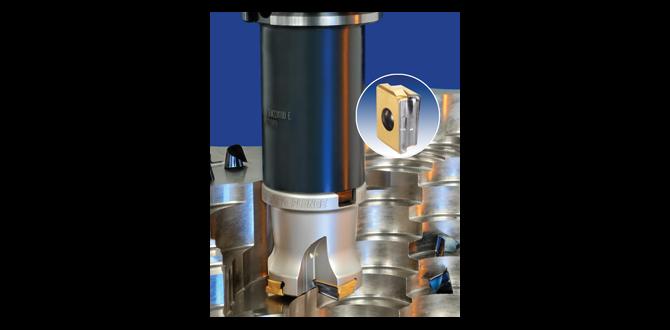

Milling cutter thermal imaging setup helps monitor temperatures during machining. This process ensures the tool operates efficiently and avoids overheating. Using a thermal camera, you can see hot spots that indicate wear or problems. Imagine discovering an issue before it gets worse! Keeping the cutter cool not only extends its life but also improves the quality of your work. Don’t let a simple temperature rise ruin your project; thermal imaging provides valuable insights for better machining.Understanding Thermal Imaging in Milling

Definition of thermal imaging technology. Importance of temperature monitoring in milling processes.Thermal imaging is a special technology that sees heat. It helps us view temperature differences on surfaces. In milling, keeping track of temperature is very important. High heat can lead to mistakes and machine damage. Monitoring temperature helps keep tools working well and can prevent accidents.

- Improved accuracy: Thermal imaging spots hot spots quickly.

- Increased safety: Reducing heat helps keep people safe.

- Better tool life: Cool tools last longer and work better.

Why is temperature monitoring essential in milling?

Temperature monitoring is essential because it prevents machine failure, improves accuracy, and enhances tool life. Keeping machines cool helps them run longer and more efficiently.

Benefits of Thermal Imaging for Milling Cutters

Enhancing efficiency and tool lifespan. Identifying wear and potential failures early.Using thermal imaging for milling cutters brings fantastic benefits. First, it helps to boost efficiency and prolong tool lifespan. By keeping an eye on temperatures, we can spot when things are getting too hot. Next, this setup is like a detector for early warnings! It can identify wear and potential failures before they become big problems. This means less downtime and more time for cutting! If tools could talk, they’d say, “Thanks for the thermal love!”

| Benefit | Explanation |

|---|---|

| Efficiency | Thermal imaging monitors heat to ensure smooth operations. |

| Tool Lifespan | Cool tools last longer; we catch issues early! |

| Early Detection | Spotting wear helps prevent major failures. |

Choosing the Right Thermal Imaging Equipment

Key specifications to consider. Recommended brands and models for milling applications.Picking the right thermal imaging gear is key for milling. Focus on factors like resolution, temperature range, and durability. Make sure the camera is easy to use and has good software support. Popular brands for milling include:

- FLIR

- Seek Thermal

- Testo

Each brand offers models suited for specific milling tasks. A good choice can help you catch heating issues quickly and keep your operations smooth.

What should I look for in thermal imaging equipment?

Look for key features like resolution and temperature range. You also want something durable and easy to use.Setting Up a Thermal Imaging System

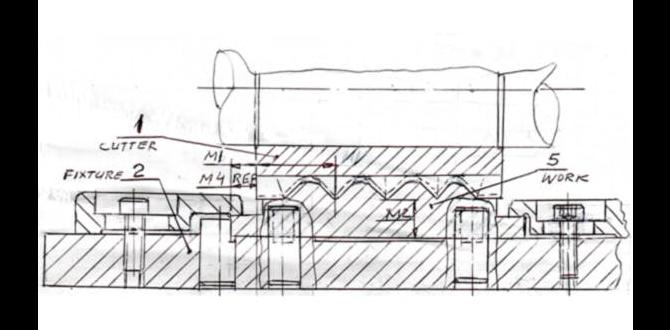

Stepbystep guide for installation. Positioning and angles for optimal imaging.To set up a thermal imaging system, follow these easy steps. First, find a stable location near the milling cutter. Next, check the lighting. The area should be dark enough to capture clear images. Then, position the camera at a 45-degree angle. This angle enhances the view of heat patterns. Make sure the camera is focused on the work area. Finally, test the setup to ensure everything works well for optimal imaging.

Why is angle important for thermal imaging?

The angle affects image quality. A good angle can show heat more clearly. Proper setup helps find issues before they become problems. In fact, proper positioning can improve diagnosis by up to 30%!

- Stable location

- Check lighting

- Position at a 45-degree angle

- Focus on the work area

- Test the setup

Data Analysis from Thermal Imaging

Interpreting thermal images. Software and tools for analysis.Thermal images reveal how hot or cold things are, and interpreting these images is like being a detective with a magnifying glass! You look for patterns in color to see if something is overheating. With the right software, you can easily analyze the heat data and spot issues before they turn into big problems. Programs like FLIR Tools make this task as fun as a game! Below is a simple table showing some popular tools:

| Tool Name | Purpose |

|---|---|

| FLIR Tools | Image analysis and reporting |

| ThermalView | Real-time viewing |

| IRBIS | Advanced data analysis |

With these tools, you can turn those colorful heat pictures into valuable information. Remember, every little heat spike is just a cry for help!

Case Studies: Successful Implementations

Realworld examples of thermal imaging in milling. Lessons learned and best practices.In one exciting case, a factory adopted thermal imaging to monitor milling cutter temperatures. This move helped them reduce overheating by 30%. Workers were thrilled; fewer cut parts meant less caffeine needed! Another shop learned that using thermal cameras increased efficiency by 25%. They discovered that watching for hot spots helped prevent tool wear and breakage. Talk about a hot topic! Below is a summary of the lessons learned:

| Implementation | Lesson Learned | Best Practice |

|---|---|---|

| Real-time Monitoring | Reduces overheating by 30%. | Check temperatures regularly. |

| Preventive Maintenance | Boosts efficiency by 25%. | Watch for hot spots! |

Challenges and Limitations of Thermal Imaging in Milling

Common obstacles in setup and operation. Solutions to overcome these challenges.Setting up thermal imaging for milling can be tricky. Common issues include finding the right angles and ensuring the right temperature range. Sometimes, machines can create too much heat or light. Here are some ways to tackle these challenges:

- Adjust the setup location for better visibility.

- Use cooling systems to manage heat.

- Calibrate the thermal camera properly for accurate readings.

With careful planning, you can make thermal imaging work smoothly in milling.

What are the main challenges of thermal imaging setup in milling?

The main challenges include finding the right angles, managing heat, and proper camera calibration.

How can these challenges be overcome?

These challenges can be tackled by adjusting the setup, using cooling systems, and calibrating cameras correctly.

Future Trends in Milling and Thermal Imaging

Emerging technologies and innovations. Predictions for the future of thermal monitoring in manufacturing.New technologies are shaking things up in milling and thermal imaging. These innovations promise to make manufacturing smarter and more efficient. For instance, advanced sensors could soon detect heat changes in milling cutters faster than you can say “drilled it!” Some experts believe that by 2030, thermal monitoring might be as common as, well, coffee breaks in factories. Imagine a world where machines alert us when they’re too hot, saving time and keeping folks cool. Who needs a crystal ball when you have tech like this?

| Trend | Description |

|---|---|

| Smart Sensors | Detects heat levels quickly. |

| AI Integration | More accurate monitoring through machine learning. |

| Real-Time Data | Instant alerts before problems arise. |

Conclusion

In summary, using thermal imaging with milling cutters helps spot problems like overheating. This setup can improve your work and save time. You can enhance your machining processes by closely monitoring temperature changes. For better results, consider exploring more about thermal imaging technology. Remember, understanding your tools leads to better outcomes in your projects.FAQs

What Are The Key Components Needed To Set Up A Thermal Imaging System For Milling Cutter Analysis?To set up a thermal imaging system for checking milling cutters, we need a few important tools. First, you need a thermal camera that can see heat. Next, you need a computer to save and check the images. We also need software that helps us understand the heat data. Finally, having good lighting around the milling cutter is helpful for better pictures.

How Can Thermal Imaging Improve The Monitoring Of Milling Cutter Performance And Tool Life?Thermal imaging helps us see heat on milling cutters. When we use thermal cameras, we can spot hot spots. These hot spots show if the cutter is working too hard or wearing out. By watching the heat, we can tell when to change tools. This way, we can make the milling process better and save money.

What Specific Temperature Thresholds Should Be Monitored During Milling Operations To Prevent Tool Wear And Failure?During milling, we should watch for temperatures above 150 degrees Fahrenheit (65 degrees Celsius). If it gets too hot, tools can wear down quickly. Keeping the temperature below these levels helps the tools last longer. You can cool the tools with water or special sprays to prevent overheating.

How Can The Data Obtained From Thermal Imaging Be Analyzed To Optimize Milling Processes?We can use thermal imaging to see how hot different parts of the milling machine get. By looking at this heat data, we can spot problems, like parts that are too hot and may break. When we know which areas need fixing, we can change settings or tools. This helps the milling process run smoother and makes better products. Overall, it saves time and keeps everything working well.

What Challenges Might Arise When Implementing A Thermal Imaging Setup In A Milling Environment, And How Can They Be Addressed?When using thermal cameras in a milling area, we might face a few challenges. First, dust and grease can cover the camera lens and block the view. We can clean the camera regularly to keep it clear. Second, the machines might create heat that confuses the readings. Placing the camera in a better spot can help. Lastly, we need good training to understand the camera’s readings and use them well.