Imagine you are a master chef making a delicious meal. What if your knife wasn’t sharp or balanced? The food wouldn’t look or taste right! This is how important the milling cutter tool is in manufacturing.

Every day, machines cut and shape materials. They need the right tools, like a milling cutter, to do their job well. But did you know that these tools have to be balanced properly? If they are not, they can create serious problems. You might even lose time and money!

Balancing a milling cutter is like ensuring a seesaw has equal weight on both sides. If one side is heavier, it can tip and break. Proper verification of balance helps tools last longer and work better. It sounds simple, yet many people overlook this step.

In this article, we will explore the world of milling cutter tool balancing verification. We will uncover why it matters, how it works, and what surprises await in your manufacturing journey. Are you ready to discover how balance can lead to success in your projects?

Milling Cutter Tool Balancing Verification: Ensuring Precision

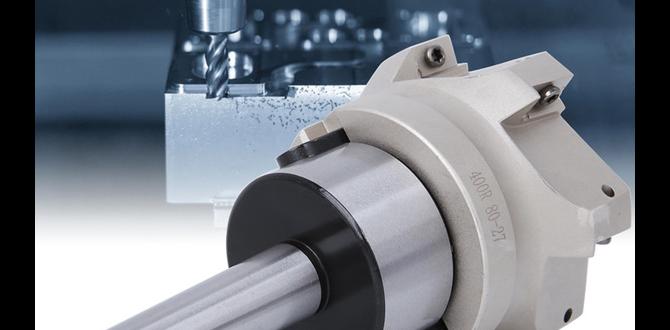

Milling cutter tool balancing verification is essential for smooth machining. Unbalanced tools can cause vibrations, leading to poor cut quality. Have you ever noticed how a shaky ride feels? That’s similar to unbalanced tools in machinery. Checking for balance ensures tools last longer and work better. Fun fact: small adjustments can make a big difference! Proper verification boosts efficiency, helping companies save time and costs. Remember, a small tool can create a big impact when balanced correctly!

Understanding Milling Cutter Tool Balancing

Definition and importance of tool balancing in machining.. The role of milling cutter tools in manufacturing processes..

Tool balancing is important in machining. It helps keep tools steady and precise. If a tool is unbalanced, it can make poor cuts and wear out quickly. This affects the quality of the products made. Milling cutter tools are key in many manufacturing processes. They shape and cut materials to create parts. When these tools are balanced, they work better, saving both time and money.

Why is tool balancing important?

Balancing tools keeps machines running well. It helps avoid mistakes and extends tool life.

Consequences of Improper Tool Balancing

Impact on machining accuracy and surface finish.. Potential risks of vibrations and tool wear..

Improper tool balancing can lead to serious problems in machining. First, it can hurt machining accuracy. This means the pieces made may not fit well. Second, it affects surface finish. Rough surfaces can cause issues later. Also, vibrations can happen when balance isn’t right. These vibrations can wear down tools faster. This can result in the need to replace tools often, costing time and money.

What are the consequences of not balancing tools?

The consequences include poor machining accuracy and a rougher surface finish, which can lead to damaged products and increased tool wear.

Key Risks of Improper Tool Balancing:

- Poor machining accuracy

- Rough surface finish

- Increased vibrations

- Higher tool wear

Step-by-Step Balancing Process

Detailed steps to carry out balancing verification effectively.. Common practices to ensure measurement accuracy..

Balancing your milling cutter tool is a bit like tuning a guitar. A few simple steps can make a big difference! First, check the tool for any visible wear or damage. Next, use a balancing machine to make measurements. This will help you spot any imbalances. Remember to always follow the manufacturer’s guidelines for accuracy. Lastly, double-check your results. A small error can lead to big problems.

| Step | Description |

|---|---|

| 1 | Inspect the milling cutter tool. |

| 2 | Measure on a balancing machine. |

| 3 | Adjust as needed. |

| 4 | Verify the final result. |

Follow these steps, and your tool will be as smooth as butter! What’s the secret? Measurement accuracy is key. So make sure to work carefully!

Best Practices for Tool Maintenance

Tips for regular maintenance to enhance tool performance.. Recommendations for storage and handling to prevent imbalance..

Keeping your tools in shape is like giving them a spa day. Regular maintenance boosts performance and extends their life. Make sure you clean your milling cutter tools after each use. Wipe off any debris and oil them lightly to keep them smooth. Store them in a dry place, away from moisture and dust. Remember, a clumsy tool is a grumpy tool, so handle them gently. Deadlifting your tools is not a good idea!

| Maintenance Tip | Storage Tip |

|---|---|

| Clean after each use | Keep in a dry area |

| Oil lightly | Avoid extreme temperatures |

| Check for damage | Use tool boxes for safety |

To prevent imbalance, always check your tools before use. If they wobble, something’s off. Regular checks mean you’ll catch problems early. Trust me, your tools will thank you with better cuts and less drama!

Common Myths and Misconceptions

Debunking myths surrounding tool balancing and its effects.. Clarifying misconceptions about the costs and time required for balancing..

Many think that balancing tools is too costly and takes too much time. This isn’t true! In fact, tool balancing can save money and improve performance. Here are some popular myths:

- Balancing tools costs too much.

- It takes too long to check.

- Balancing is only for big machines.

Balancing helps maintain the quality of work and extends tool life. A quick check can make a big difference!

What are the real costs and time needed for balancing?

The truth is, balancing takes less time than you think and can actually save money in the long run. Regular checks keep machinery in top shape, reducing repairs and downtime.

Future Trends in Tool Balancing Technology

Innovations in tools and techniques for improved balancing.. The role of automation and AI in balancing verification processes..

New tools and methods are changing how we think about milling cutter tool balancing verification. Innovations focus on making tools lighter and easier to use. This helps workers balance tools faster and more accurately. Automation is also a big player. Machines now use artificial intelligence (AI) to check balance. AI analyzes data quickly, helping in making better decisions.

- Smart sensors measure cutting tools with precision.

- Robotic systems take over tedious balancing tasks.

- AI predicts issues before they happen, saving time and costs.

How does AI improve tool balancing?

AI improves tool balancing by analyzing data faster than humans. It helps find problems before they become serious.

Conclusion

In conclusion, verifying the balance of milling cutter tools is essential for smooth machining. It prevents vibrations and improves precision. By regularly checking balance, you ensure better tool life and high-quality results. We encourage you to explore more about this process and practice it in your work. You’ll see the benefits firsthand in your projects!

FAQs

What Are The Key Indicators That A Milling Cutter Tool Is Out Of Balance, And How Can These Be Identified During Operation?

You can tell a milling cutter tool is out of balance if it shakes while working. You might hear loud noises or feel vibrations in the machine. It can also make uneven cuts in the material, so the final result might look strange. To find these problems, you can listen and watch closely while the machine runs. If you notice any of these signs, the tool may need fixing or replacing.

What Methods And Technologies Can Be Used To Verify The Balance Of A Milling Cutter Tool Before And After Machining?

To check if a milling cutter tool is balanced, you can use a tool balancer. This device spins the cutter and shows if it wobbles. We can also use special scales to weigh the tool from different sides. If it feels even and doesn’t shake, it’s ready for use. Doing this helps make sure the tool cuts perfectly!

How Does Tool Imbalance Affect The Quality Of The Finished Product And The Overall Efficiency Of The Milling Process?

Tool imbalance can make the milling process less effective. When tools aren’t balanced, they can shake or vibrate. This shaking can lead to mistakes in the product we make. It can also slow down our work, making it take longer to finish. To keep everything running smoothly, we need balanced tools!

What Are The Recommended Practices For Conducting Routine Balance Checks On Milling Cutter Tools To Ensure Optimal Performance?

To keep milling cutter tools working well, you should check their balance regularly. First, make sure the tools are clean and free of dirt. Next, use a special tool called a balancer to see if they are even. If one side feels heavier, you may need to adjust it. Finally, always follow the manufacturer’s instructions for the best results.

How Can The Design And Manufacturing Processes Of Milling Cutter Tools Be Improved To Reduce The Likelihood Of Balance Issues Arising?

We can improve the design and making of milling cutter tools by using better materials. Choosing stronger and lighter materials helps keep the tool balanced. We should also check the tools carefully to find any mistakes during making. Using machines that are more precise can help make everything fit just right. This way, we can lower the chances of balance problems happening.