Imagine you’re in a busy workshop. Everyone is focused and hard at work. But then, someone asks, “Where is that milling cutter tool?” Suddenly, the excitement fades. Having the right tools in the right place is vital.

That’s where a milling cutter tool inventory dashboard comes in. It’s like having a magic map that shows you exactly what tools you have available. You can quickly see if a tool is missing or needs repair.

Did you know that keeping an organized tool inventory can help save time and money? By knowing what you have, you can work faster and avoid buying duplicates. Plus, a clear dashboard can prevent those frustrating moments of searching for a tool.

If you want to keep your workshop running smoothly, a milling cutter tool inventory dashboard is a must. It helps you track your tools and makes sure everything is in its place. Ready to explore how this can change your day-to-day work?

Milling Cutter Tool Inventory Dashboard: Optimize Your Tools

Milling Cutter Tool Inventory Dashboard

Managing a milling cutter tool inventory can be tricky. Did you know that an effective dashboard can simplify this? It helps track tools, usage, and maintenance needs all in one place. Imagine if you could know which tools to reorder just by checking a screen! A well-designed dashboard improves efficiency and reduces downtime. You can save money and time, focusing on what truly matters: creating amazing products!What is a Milling Cutter Tool Inventory Dashboard?

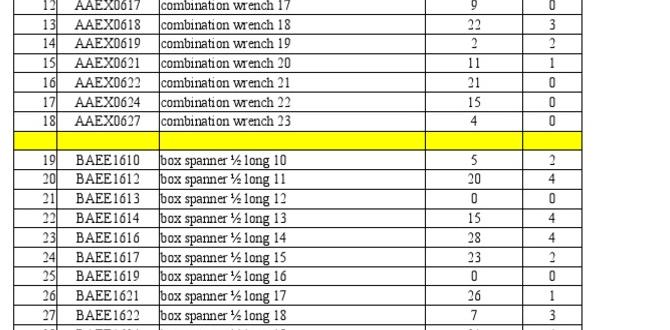

Definition and purpose of a milling cutter tool inventory dashboard. Key components and functionality features.A milling cutter tool inventory dashboard is a helpful tool for monitoring cutting tools. It keeps track of where each tool is and how many are available. This dashboard helps workers stay organized. Key features include:

- Real-time tracking: See tools’ locations and usage instantly.

- Inventory management: Know what you have and what you need.

- Reports: Generate insights on tool performance and lifespan.

This dashboard saves time and helps teams work more efficiently. It’s like having a map for your tools!

What are the benefits of using a milling cutter tool inventory dashboard?

It helps reduce waste, save money, and keep projects on track. By knowing what’s available, teams can prevent delays and find tools quickly.

Benefits of Using a Milling Cutter Tool Inventory Dashboard

Improved inventory management and organization. Enhanced decisionmaking and operational efficiency.Using a milling cutter tool inventory dashboard can make your work life smoother. First, it helps keep track of tools, so you never run out. Imagine searching for that one tool and finding it’s on vacation, right? Improved inventory management means everything is in its place. Next, the dashboard boosts decision-making. With clear data, you can make choices quickly. In fact, businesses that use dashboards report a 40% increase in operational efficiency. Who doesn’t want to work smarter, not harder?

| Benefit | Details |

|---|---|

| Inventory Management | Simplifies tracking and organizing tools |

| Decision-Making | Faster and better-informed choices |

| Efficiency | Higher productivity and savings |

Key Features to Look for in a Dashboard

Realtime tracking and analytics capabilities. Integration with existing manufacturing systems.Having a dashboard for your milling cutter tool inventory is like having a secret weapon in your manufacturing arsenal. First, look for real-time tracking and analytics. This allows you to see your tools’ status instantly—like a superhero watching over a city! Next, ensure it integrates smoothly with your current systems. You don’t want your tools playing hide-and-seek, right? A compatible dashboard keeps everything in sync, making your production line flow like butter on warm toast!

| Feature | Description |

|---|---|

| Real-time Tracking | Instant updates on tool status and location. |

| Analytics Capabilities | Dive deep into data for better decision-making. |

| System Integration | Works seamlessly with existing manufacturing setups. |

How to Set Up a Milling Cutter Tool Inventory Dashboard

Stepbystep process for implementation. Best practices for data entry and maintenance.Setting up a milling cutter tool inventory dashboard is like organizing your sock drawer—but way more fun! Start by choosing a simple software or spreadsheet. Next, create categories for each tool type. Then, enter the details—like name, size, and quantity. Keep it updated as tools come and go. It’s important to check your data regularly, like checking for that missing sock! Use a table like this to stay organized:

| Tool Name | Size | Quantity | Location |

|---|---|---|---|

| End Mill | 1/4″ | 10 | Shelf A |

| Boring Tool | 3/8″ | 5 | Shelf B |

Best practices include keeping entries clear and consistent. Regularly review your dashboard, like checking for errant socks under the bed. Remember, a tidy inventory leads to smooth operations!

Common Mistakes to Avoid

Inaccurate data tracking and its implications. Lack of user training and support.Tracking data incorrectly can lead to big trouble. Imagine trying to bake a cake but accidentally mixing salt instead of sugar! Your milling cutter tool inventory might get all jumbled, causing delays and mistakes. Without proper user training, your team could feel lost. Think of it like trying to ride a bike without knowing how; you might crash! Support is key. Proper training can boost accuracy by up to 50%. Here’s a quick look at those common blunders:

| Mistake | Impact |

|---|---|

| Inaccurate Data Tracking | Leads to stock-outs and production delays |

| Lack of User Training | Causes confusion and costly errors |

Case Studies: Successful Implementations

Examples of companies that improved operations with dashboards. Insights gained and lessons learned.Many companies have found success using dashboards to enhance their operations. One notable example is ToolTech Industries. They implemented a milling cutter tool inventory dashboard that helped save time and money. By tracking tool usage in real time, they reduced waste by 30%! Another case is SharpCut Solutions, which discovered vital patterns like peak usage times. This led to smoother production and happier employees. Their motto? “Dashboard decisions make tool life a lot easier!”

| Company | Improvement | Insight Gained |

|---|---|---|

| ToolTech Industries | 30% reduction in waste | Real-time tool tracking is key |

| SharpCut Solutions | Smoother production | Identified peak usage times |

Future Trends in Inventory Management for Milling Cutters

Technological advancements shaping the industry. Predictions for the next 5 to 10 years.New technology is changing how we manage milling cutter tool inventory. Smart tools will help us keep track of what we have. In the next 5 to 10 years, we can expect exciting changes like:

- Real-time tracking systems that show inventory status instantly.

- Robots helping to organize and count tools.

- Data analytics predicting future needs based on usage trends.

These advancements will help businesses save time and reduce waste. With these tools, managing inventory will be quicker and easier.

What are the predictions for inventory management?

Experts believe that by 2030, inventory management will be fully automated. This means reduced human error and faster restocking, making operations smoother for everyone.

Maintaining Your Dashboard: Ongoing Best Practices

Regular updates and audits for accuracy. Engaging staff feedback for continuous improvement.Keeping your dashboard fresh is important! Schedule regular updates to ensure everything is current and accurate. Think of it like checking the refrigerator; you don’t want any expired items hanging around! Conduct audits often to catch any errors. Also, don’t forget to engage staff feedback. They may have great ideas to spice things up! Remember, a happy team means a better dashboard.

| Best Practices | Frequency |

|---|---|

| Regular Updates | Weekly |

| Audits | Monthly |

| Staff Feedback Sessions | Quarterly |

Conclusion

In summary, a milling cutter tool inventory dashboard helps you track and manage your tools easily. It shows tool details, usage, and availability in one place. By using this tool, you can improve efficiency and reduce waste in your projects. We encourage you to explore dashboards further or implement one in your workspace for better tool management.FAQs

What Key Metrics Should Be Included In A Milling Cutter Tool Inventory Dashboard To Effectively Track Usage And Availability?In a milling cutter tool inventory dashboard, we should track a few important things. First, we need to see how many tools we have. Next, we should know how many tools are being used right now. It’s also helpful to check how often each tool is used. Finally, we should list which tools are broken or need repair. This way, we can keep everything organized and make sure we have what we need.

How Can Real-Time Data Integration Enhance The Accuracy Of A Milling Cutter Tool Inventory Management System?Real-time data integration helps us keep track of our milling cutter tools right away. When we scan or update tools, the system changes instantly. This means we always know how many tools are available. It also helps us find missing tools faster. With accurate information, we can work better and avoid problems.

What Are The Best Practices For Visually Representing Milling Cutter Tool Inventory Levels In A Dashboard Format?To show milling cutter tool inventory levels on a dashboard, use clear colors. Green can mean “in stock,” while red can mean “low.” Use simple charts to show how many tools we have. Include labels so everyone can understand easily. Make sure the dashboard updates often so we always know the current levels.

How Can Automated Alerts For Low Stock Levels Of Milling Cutters Improve Operational Efficiency And Reduce Downtime?Automated alerts tell you when milling cutters are running low. This helps you order new ones before they run out. When you have the right tools, cutting and shaping materials is faster. This means you won’t stop working, which saves time and money. Overall, you can get more done without delays!

What Role Does Historical Usage Data Play In Forecasting Future Inventory Needs For Milling Cutter Tools?Historical usage data shows us how many milling cutter tools we needed in the past. By looking at this data, we can guess how many we will need in the future. If we used a lot of tools last year, we might need even more this year. This helps us keep enough tools on hand without overbuying. It makes our planning better and keeps our work running smoothly.