Have you ever wondered how factories keep track of the tools they use? It’s more important than you might think. One key tool is the milling cutter. These cutters help shape and cut materials into different forms.

In the busy world of manufacturing, a milling cutter tool tracking system is vital. It helps everyone know where each cutter is. Imagine a chef losing their favorite knife. It would make cooking very hard! The same goes for workers who need the right tools.

Setting up this tracking system can be tricky but rewarding. It saves time, prevents mistakes, and makes work smoother. Wouldn’t it be nice to know exactly where your tools are at all times? In this article, we will explore how to set up a milling cutter tool tracking system. You will learn tips and tricks to make the process easier.

So, let’s jump in and discover how a good tracking system can change the way we work!

Milling Cutter Tool Tracking System Setup: A Complete Guide

Milling Cutter Tool Tracking System Setup

Setting up a milling cutter tool tracking system can seem tricky, but it doesn’t have to be. First, choose the right tools to help keep track of your cutters. Next, label everything clearly. This helps you find tools quickly, saving time during projects. Did you know that losing track of tools can waste up to 20% of a workday? By using an organized tracking system, you can boost efficiency and focus on what really matters: creating!Understanding Milling Cutter Tools

Definition and types of milling cutter tools.. Importance in manufacturing and machining processes..Milling cutter tools are essential in shaping and cutting materials. They come in different types, each serving a unique purpose. For example, end mills are great for making slots, while face mills excel in providing a flat surface. These tools are the superstars in manufacturing and machining, turning raw materials into finished products. Surprisingly, without them, making your favorite toy would be pretty tough! Here’s a quick breakdown:

| Type of Milling Cutter | Use |

|---|---|

| End Mill | Cutting slots or holes |

| Face Mill | Creating flat surfaces |

| Ball Nose Mill | Curved shapes |

In the world of production, understanding these tools can make all the difference between a smooth operation and a total mess. It’s like choosing the right utensil for your pizza! Want to make it delicious? Use the right tools!

Benefits of Implementing a Tool Tracking System

Enhanced precision and quality control.. Reduction in tool inventory and costs..Using a tool tracking system can make your work life easier and more precise. First off, it improves precision and quality control. You can find the right tool quickly, reducing mistakes. Plus, it helps keep your workspace tidy. Who likes a messy tool box anyway? Additionally, it cuts down on tool inventory and costs. Less clutter means less spending. Many businesses report savings of up to 30%! Isn’t that worth a cheerful high-five?

| Benefit | Description |

|---|---|

| Enhanced Precision | Quick access leads to fewer mistakes. |

| Lower Costs | Less inventory means less money spent. |

Steps to Set Up a Tool Tracking System

Initial assessment and planning for tool inventory.. Installation and configuration of hardware components..To set up a tool tracking system, first assess your tool inventory. This helps you understand what you have. Count each tool and check their condition. Then, plan how to organize them efficiently.

Next, install and configure the necessary hardware. This includes the tracking devices and any software you will use. Make sure everything connects properly. Follow these steps:

- Gather tools and check their status.

- Choose suitable tracking devices.

- Set up software on your computer.

- Connect devices to the system.

Creating a good setup leads to better management of tools.

What is the importance of planning for tool inventory?

Planning helps understand your tools better and ensures everything is organized. This makes it easier to track usage and maintain the tools.

Why do we need to install hardware components?

Installing hardware components helps keep tools in check and ensures they are found quickly when needed.

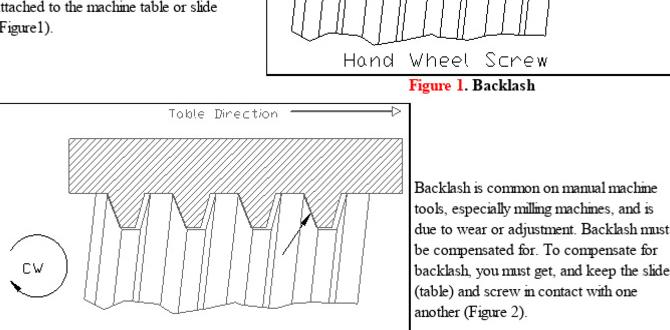

Integrating the Tracking System with Existing Machinery

Compatibility considerations with CNC and manual machines.. Software integration with manufacturing execution systems (MES)..Before mixing and matching, check if your tracking system plays nice with both CNC and manual machines. It’s like trying to fit a square peg in a round hole! Compatibility is key. Software integration should also be seamless with your manufacturing execution systems (MES). Otherwise, your new tool might just end up being a very expensive paperweight. Let’s keep things running smooth, like butter on hot toast!

| Machine Type | Compatibility |

|---|---|

| CNC Machines | High compatibility, but check software requirements. |

| Manual Machines | Possible, but requires extra adapters. |

Data Management and Analysis in Tool Tracking

Importance of data collection and reporting.. Tools for data analysis and visualization..Collecting data is key to tracking tools like milling cutters. It helps us see how well tools work, find problems, and make things better. Good data leads to smart decisions. We can use cool tools for data analysis, like graphs and charts, to visualize information easily. This way, workers can understand data at a glance.

- Importance of data collection: Helps spot trends and improve performance.

- Tools for data visualization: Graphs and tables make data easy to understand.

Why is data management important in tool tracking?

Data management helps improve efficiency and reduce errors in milling cutter tools by allowing tracking of usage, wear, and performance. An organized approach ensures all tool statuses are clear and available for analysis.

Best Practices for Maintaining the Tool Tracking System

Regular audits and system updates.. Employee training and engagement..To keep your tool tracking system running smoothly, regular check-ups are key. Conduct audits to catch any problems before they grow. This ensures everything is up to date. Engaging your workers in training builds their skills. It helps them use the system better. Try these ideas:

- Schedule audits every month.

- Update software and tools regularly.

- Hold training sessions at least twice a year.

These steps will enhance the system’s performance.

Why are audits important?

Regular audits help find hidden issues and ensure everything works well.

How can training help employees?

Training boosts employee confidence and ability to use the tool tracking system.

Common Challenges and Solutions in Tool Tracking Setup

Identifying potential implementation pitfalls.. Strategies for overcoming resistance to change..Setting up a tool tracking system can be tricky. Common problems include poor planning or lack of support from staff. To overcome these issues, open communication is key. Share the benefits of the system with your team. Listen to their concerns and provide training. This helps everyone adjust to the change.

- Involvement leads to ownership.

- Training builds confidence.

- Support shows commitment to success.

With teamwork and proper planning, you can make the tracking setup smooth and effective. Remember, a little effort can lead to big improvements!

What are common challenges in tool tracking setup?

Challenges include poor planning, lack of support, and employee resistance to change.

How can we handle resistance to change?

- Communicate benefits clearly.

- Offer training sessions.

- Involve employees in the plan.

Future Trends in Tool Tracking Technology

Innovations in smart tooling and automation.. The role of IoT and Industry 4.0 in milling processes..Exciting times are ahead for tool tracking technology! Innovations like smart tooling and automation mean less time searching for tools and more time creating masterpieces. Imagine your milling cutter tools telling you where they are—like they’ve got little GPS trackers! That’s the magic of IoT and Industry 4.0. These technologies make milling processes faster and smarter. With data flowing through machines, we can track tools in real-time. It’s like giving your tools a superpower!

| Trend | Description |

|---|---|

| Smart Tooling | Tools that communicate their location. |

| Automation | Less manual work, more fun! |

| IoT Integration | Real-time tracking everywhere. |

| Industry 4.0 | Bringing intelligence to milling. |

Conclusion

In summary, setting up a milling cutter tool tracking system can improve your efficiency and accuracy. You should choose the right tools, install software, and train your team. Remember to regularly check your system for updates. If you follow these steps and stay informed, you’ll have a smoother operation. Explore more resources online to deepen your understanding!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Milling Cutter Tool Tracking System Setup:Sure! A milling cutter tool tracking system helps us find and follow tools we use for cutting metal. First, we need a good plan to set it up. Then, we can use special machines to track the tools. This makes sure we always know where they are. Finally, we can make our work faster and safer!

Sure! Please ask your question, and I’ll answer it in a simple way.

What Are The Key Components Required To Establish An Effective Milling Cutter Tool Tracking System?To create a good milling cutter tool tracking system, you need a few important parts. First, you need a way to keep track of each tool’s location. Then, you need a log to record how often each tool is used. We should also have a system to check when tools need maintenance or replacing. Finally, it’s helpful to use software to organize everything easily.

How Can Rfid Technology Be Integrated Into A Milling Cutter Tool Tracking System To Enhance Efficiency?We can use RFID, which stands for Radio Frequency Identification, on milling cutter tools. Each tool gets a small tag that sends signals. You can track where each tool is and if it’s working well. This helps us find tools faster and keep them in good shape. In the end, we save time and work better!

What Software Solutions Are Available For Monitoring And Managing Milling Cutter Tool Inventory And Usage?You can use special software to keep track of milling cutters. Some programs help you see how many tools you have. Others can tell you when a tool needs to be replaced. Popular options include Tool Management Software and Inventory Tracking Tools. These programs make managing your tools easier and help you use them better.

How Do You Ensure Accurate Calibration And Maintenance Of The Tracking System For Milling Cutter Tools?To keep the tracking system accurate, we check it often. First, we use special tools to measure the cutters’ position. If something is wrong, we fix it right away. We also clean the system regularly to prevent problems. This helps our milling cutters work well every time.

What Challenges Might Arise During The Implementation Of A Milling Cutter Tool Tracking System, And How Can They Be Mitigated?When we start using a milling cutter tool tracking system, we might face some problems. First, it can be hard to get everyone to learn how to use it. To fix this, we can give clear training and support. Second, the tools might not always be easy to find if they get mixed up. We can solve this by labeling them clearly and keeping them organized. Lastly, computers can sometimes fail, so we should have backup plans ready.