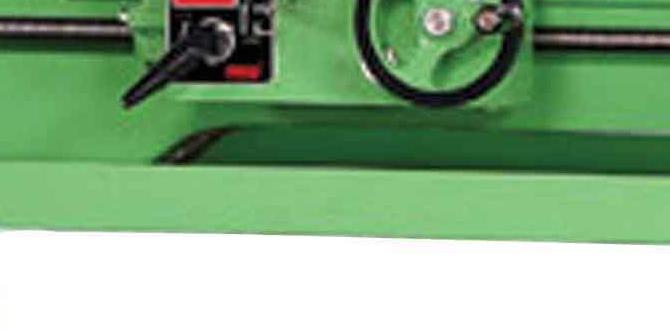

Have you ever wondered how precise tools help create perfect parts? In the world of manufacturing, milling cutter toolholder alignment plays a crucial role. Proper alignment ensures that the milling cutter works perfectly with the toolholder. This is important because even a tiny mistake can lead to big errors in production.

Imagine trying to cut a cake with a wobbly knife. It just wouldn’t work well, right? The same idea applies to milling machines. When the cutter and toolholder are not aligned, it can cause rough edges and wasted materials. This is where alignment testing comes in.

Fun fact: Did you know that a small misalignment can affect the final product’s quality? It’s true! That’s why businesses take alignment testing seriously. They want to avoid costly mistakes. In this article, we will explore how this testing is done and why it matters.

Milling Cutter Toolholder Alignment Testing: Ensuring Precision

Milling Cutter Toolholder Alignment Testing

Milling cutter toolholder alignment testing is important for creating precise parts. It checks if the toolholder fits correctly into the machine. Did you know that misalignment can cause the tool to wear out faster? Proper alignment not only extends tool life but also improves the quality of the work. Measuring tools help ensure everything lines up well. Keeping your equipment aligned leads to smoother operations and better results in machining tasks.Understanding Toolholder Alignment

Definition of toolholder alignment in milling.. Importance of accurate alignment for machining efficiency..Toolholder alignment in milling refers to how perfectly the cutting tool fits in its holder. Think of it like a snug glove! Accurate alignment is essential for effective machining. If things are off-kilter, it can lead to poor cuts, tool wear, and even accidents. A study shows that proper alignment can boost efficiency by up to 30%. So, keeping everything straight is not just about precision; it’s about safety and saving time too!

| Benefit | Impact |

|---|---|

| Better Cuts | Higher quality finishes |

| Tool Longevity | Less wear and tear |

| Time Efficiency | Fewer mistakes |

Indications of Misalignment

Symptoms of misalignment during machining.. Consequences of improper toolholder alignment on the workpiece..Sometimes, machines can act a bit strange, like they’ve had too much coffee! Signs of misalignment during machining are hard to miss. You might hear funny noises, see uneven cuts, or notice a rough surface on your workpiece. This can be a big problem!

If the toolholder isn’t aligned properly, it can ruin your work. Imagine a pizza cutter that doesn’t cut straight—chaos! The tool may wear out faster, wasting time and money. Even worse, it could damage the machine or the workpiece. So, keep an eye out for those misalignment signs!

| Symptoms of Misalignment | Consequences |

|---|---|

| Uneven cuts | Damaged workpiece |

| Unusual noises | Increased wear on tools |

| Rough surface finish | More production time |

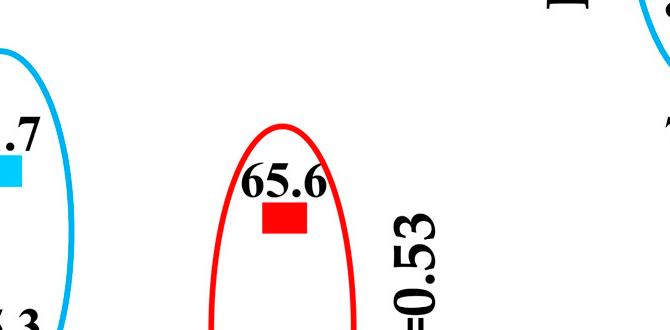

Testing Methods for Toolholder Alignment

Common techniques for alignment testing (e.g., laser alignment).. Pros and cons of each method..Different ways exist to test toolholder alignment. One popular method is laser alignment. This technique uses lasers to check the toolholder’s position, ensuring it is straight like an arrow. The good side? It’s super accurate! But, it can be pricey. Another common method is using dial indicators. They are more budget-friendly but may not be as precise. So, it’s a balance between cost and accuracy. Here’s a quick look:

| Method | Pros | Cons |

|---|---|---|

| Laser Alignment | High accuracy | Expensive |

| Dial Indicators | Cost-effective | Less precise |

Choosing the right method can feel like picking the best ice cream flavor. Each option has its flavor, but it depends on your taste and budget!

Tools and Equipment for Alignment Testing

Essential tools for performing alignment tests.. Recommended specifications for optimal testing..For checking the alignment of milling cutter toolholders, you need some key tools. These tools help ensure everything is in the right place. Remember, the right tools make testing easier and more accurate. Here are two important types:

- Dial Indicators: These should have a resolution of at least 0.001 mm for precise readings.

- Alignment Tools: Choose those made from sturdy materials to resist wear over time.

Using good-quality tools can drastically improve your test results!

What tools are best for alignment testing?

Some recommended tools include dial indicators, alignment fixtures, and precision levels. These help ensure your milling cutter toolholder is properly aligned, making your work more accurate and efficient.

Best Practices for Toolholder Alignment

Stepbystep guide for achieving precise alignment.. Maintenance tips to ensure ongoing alignment accuracy..To achieve precise toolholder alignment, follow these steps:

- Begin by cleaning the toolholder and milling cutter.

- Use a dial indicator for accuracy.

- Align the toolholder vertically and horizontally.

- Check the measurements multiple times.

- Once aligned, secure the toolholder carefully.

For ongoing accuracy, remember these maintenance tips:

- Regularly check alignment every few weeks.

- Keep tools and holders clean to prevent errors.

- Tighten all components firmly after adjustments.

- Store tools properly to avoid misalignment.

With practice, toolholder alignment will become easier. Just take your time for the best results!

How often should I check my toolholder alignment?

Regular checks every two weeks are beneficial for accurate results. Keeping an eye on the alignment helps maintain performance and prevent mishaps.

Case Studies: Real-World Applications

Examples of improved machining processes through alignment testing.. Lessons learned from misalignment incidents..Imagine two friends trying to stack blocks. If one is off, the tower wobbles! That is what happened in a machine shop that skipped alignment testing. Misalignment led to extra costs and broken tools. But with alignment tests, they fixed their setup and improved production. They went from making a few parts a day to a surprising “wow” number! Lessons learned: always check your tools. As they say, “Measure twice, cut once!”

| Incident | Impact | Improvement |

|---|---|---|

| Misalignment | Extra costs | Increased efficiency |

| Tool wear | Frequent replacements | Longer lifespan |

So, remember: alignment testing isn’t just a good idea—it’s a game changer!

Common Challenges and Solutions

Typical obstacles faced in toolholder alignment.. Effective solutions and techniques to overcome these challenges..Milling cutter alignment has some typical challenges. These include incorrect positioning, wear of the tool, and vibration during operation. Each of these can lead to poor cutting results and extra costs. Thankfully, there are solutions to these problems.

- Regular checking of toolholder settings helps maintain accuracy.

- Using precise measuring tools ensures proper alignment.

- Reducing vibration through machine maintenance can improve performance.

By addressing these challenges, you can achieve better results in your milling processes.

What are common issues in toolholder alignment?

Typical issues include incorrect positioning, tool wear, and vibrations.

How can these issues be solved?

Regular maintenance and precise measurements are key solutions. This can greatly improve the alignment and performance of your milling operations.

Future Trends in Toolholder Alignment Technology

Innovations in alignment testing tools and techniques.. The role of automation and AI in precision alignment..Get ready to see some really cool upgrades in toolholder alignment! New testing tools are popping up, making it easier than ever to check if everything lines up just right. Imagine a world where robots and AI take on these tasks—no more squinting to see if things are off! With precision like never before, human error fades away, leaving only accuracy. Plus, it might give you more time to become the champion of your snack game at work!

| Innovation | Impact |

|---|---|

| Smart Alignment Tools | Faster and more accurate results! |

| Automation | Less human error, more fun! |

In fact, studies show that automated systems could reduce errors by up to 30%. That’s like finding a quarter in your old jeans every day! With these advancements, the future looks bright for toolholder alignment, and we can’t wait to see how it unfolds!

Conclusion

In conclusion, testing the alignment of milling cutter toolholders is essential for accuracy and efficiency. Proper alignment helps avoid mistakes and improves your work quality. Always check your toolholder alignment before starting a project. For more information, dive into related articles or guides. Understanding this process will help you become a better and more precise machinist.FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Toolholder Alignment Testing:Milling cutter toolholder alignment testing is about making sure the tool is straight. If it’s not, the cuts won’t be smooth. We can test this by checking how well the cutter sits in the holder. You can use special tools to help see if everything lines up. Being straight helps make better parts when we cut things.

Sure! Please share the question you want me to answer.

What Are The Most Common Methods Used For Testing The Alignment Of Milling Cutter Toolholders In Cnc Machines?To test if a milling cutter toolholder is aligned in a CNC machine, we can use a few simple methods. First, we can use a dial indicator, which shows if the toolholder is straight. Next, we can use a laser tool to see if the cutting tool is in the right spot. Finally, we can check with special gauges that help us see if everything is straight. These methods help us make sure our tools work well and cut correctly.

How Does Improper Alignment Of Toolholders Affect Machining Precision And Part Quality?Improper alignment of toolholders can make machines work less accurately. When toolholders are not straight, tools can cut in the wrong place. This can create parts that don’t fit well or have rough edges. If we want to make good parts, it’s important to make sure everything is lined up correctly. Good alignment helps us create better quality and precise pieces.

What Tools And Equipment Are Typically Utilized To Check For Alignment Discrepancies In Milling Cutter Toolholders?To check if milling cutter toolholders are aligned correctly, we use a few simple tools. One tool is a dial indicator, which measures small distances accurately. Another tool is a caliper, which helps us check the space between parts. We might also use a level to see if everything is flat. By using these tools, we can make sure everything works perfectly.

What Steps Should Be Taken To Properly Align A Milling Cutter Toolholder Before Beginning A Machining Operation?To align a milling cutter toolholder, first, make sure the machine is turned off and safe. Then, check that the toolholder fits snugly into the spindle. Next, use a dial indicator to measure and adjust the height of the toolholder. Finally, tighten everything securely and double-check your alignment before starting the machine. This helps ensure your work is accurate and safe!

How Often Should Alignment Testing Be Performed On Milling Cutter Toolholders To Ensure Optimal Machining Performance?You should check the alignment of milling cutter toolholders often. It’s best to do this every time you change the tool. You can also check after a lot of use or after any bumps. This helps make sure your machine works well and makes good cuts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Toolholder Alignment Testing:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Milling cutter toolholder alignment testing is about making sure the tool is straight. If it’s not, the cuts won’t be smooth. We can test this by checking how well the cutter sits in the holder. You can use special tools to help see if everything lines up. Being straight helps make better parts when we cut things.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Most Common Methods Used For Testing The Alignment Of Milling Cutter Toolholders In Cnc Machines? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To test if a milling cutter toolholder is aligned in a CNC machine, we can use a few simple methods. First, we can use a dial indicator, which shows if the toolholder is straight. Next, we can use a laser tool to see if the cutting tool is in the right spot. Finally, we can check with special gauges that help us see if everything is straight. These methods help us make sure our tools work well and cut correctly.”}},{“@type”: “Question”,”name”: “How Does Improper Alignment Of Toolholders Affect Machining Precision And Part Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper alignment of toolholders can make machines work less accurately. When toolholders are not straight, tools can cut in the wrong place. This can create parts that don’t fit well or have rough edges. If we want to make good parts, it’s important to make sure everything is lined up correctly. Good alignment helps us create better quality and precise pieces.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Typically Utilized To Check For Alignment Discrepancies In Milling Cutter Toolholders? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if milling cutter toolholders are aligned correctly, we use a few simple tools. One tool is a dial indicator, which measures small distances accurately. Another tool is a caliper, which helps us check the space between parts. We might also use a level to see if everything is flat. By using these tools, we can make sure everything works perfectly.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Properly Align A Milling Cutter Toolholder Before Beginning A Machining Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a milling cutter toolholder, first, make sure the machine is turned off and safe. Then, check that the toolholder fits snugly into the spindle. Next, use a dial indicator to measure and adjust the height of the toolholder. Finally, tighten everything securely and double-check your alignment before starting the machine. This helps ensure your work is accurate and safe!”}},{“@type”: “Question”,”name”: “How Often Should Alignment Testing Be Performed On Milling Cutter Toolholders To Ensure Optimal Machining Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the alignment of milling cutter toolholders often. It’s best to do this every time you change the tool. You can also check after a lot of use or after any bumps. This helps make sure your machine works well and makes good cuts!”}}]}