Imagine you are in a busy workshop. The sound of machines buzzing fills the air. Among all the tools, one stands out: the milling cutter. But have you ever thought about how important its tooth pitch is?

Tooth pitch is the space between each tooth on the cutter. This small detail can make a huge difference in how well the cutter performs. Just like a well-tuned bicycle rides better, the right tooth pitch helps the milling cutter work more effectively.

But how do you choose the best tooth pitch? What happens if it’s too tight or too wide? These questions can puzzle many. Luckily, optimizing the tooth pitch can help both new and experienced users get the most from their milling cutters.

In this article, we will explore the fascinating world of milling cutter tooth pitch optimization. We will share tips, tricks, and surprising facts that can help you achieve great results. Ready to dive in?

Milling Cutter Tooth Pitch Optimization: Enhancing Performance

Milling Cutter Tooth Pitch Optimization

Milling cutter tooth pitch optimization helps improve cutting efficiency. By adjusting the pitch, manufacturers can achieve smoother finishes and faster cutting times. Do you know that the right tooth spacing can reduce wear on tools? This leads to longer tool life and less downtime. Proper optimization not only enhances production rates but also lowers costs. Discover how fine-tuning tooth pitch can transform your milling process into a more productive and cost-effective operation.Understanding Milling Cutters

Definition and function of milling cutters. Types of milling cutters in the industry.Milling cutters are special tools used in machines to shape and cut materials like metal and wood. They have sharp edges that help make precise cuts. Different types of milling cutters exist. Some common types include:

- Face Cutters: These cut flat surfaces.

- End Mills: They create complex shapes.

- Slot Drills: They make narrow slots.

Each type serves a specific purpose in the manufacturing process, making milling a vital part of production.

What are milling cutters?

Milling cutters are tools designed for removing material from a workpiece. They operate through rotating edges to create different shapes and surfaces. This grinding effect controls the precision of the final product.

The Importance of Tooth Pitch

Explanation of tooth pitch and its role in milling. Impact of tooth pitch on cutting performance and surface finish.Tooth pitch is the distance between the cutting edges of a milling cutter. It plays a big role in how well the machine cuts. Think of it like spacing between dancers on a dance floor; if they’re too close, it gets messy! A proper tooth pitch helps with cutting performance and gives you a smoother surface finish. Too wide, and you might get rough edges; too tight, and you’ll wear out your cutter quickly. The right pitch can make all the difference!

| Tooth Pitch Effects | Outcome |

|---|---|

| Poor Tooth Pitch | Rough Surface Finish |

| Optimal Tooth Pitch | Smooth Surface Finish |

So, next time you pick a milling cutter, remember: choose wisely! Your workpiece will thank you!

Factors Influencing Tooth Pitch Optimization

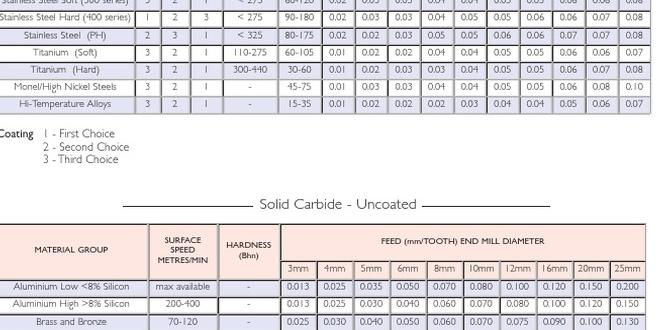

Material properties and their effects on tooth pitch. Cutting speed and its relation to tooth pitch design.Many factors play a role in the optimization of tooth pitch for milling cutters. First, consider the material being cut. Harder materials can require tighter tooth pitches. This helps to maintain cutting efficiency. Meanwhile, the cutting speed is equally important. Faster speeds can lead to smoother finishes with the right pitch. Too fast, and you might just end up with a wobbly mess! Below is a simple table showing how material and speed affect tooth pitch.

| Material | Recommended Tooth Pitch | Cutting Speed |

|---|---|---|

| Soft Metals | Wider Pitch | High Speed |

| Hard Metals | Narrow Pitch | Moderate Speed |

To sum it up, material properties and cutting speed are key to tooth pitch optimization. Choose wisely, or your cutting tool might just laugh at you!

Methods for Optimizing Tooth Pitch

Analytical approaches for calculating ideal tooth pitch. Computational techniques and simulation tools available.Finding the best tooth pitch is like picking the right shoe size—it just makes everything smoother! There are smart ways to calculate the perfect tooth pitch. One method is an analytical approach, where you use formulas to figure out what works best. Computational techniques and simulation tools also help. They provide a virtual playground to test ideas without creating a mess! Check out this handy table for a quick overview:

| Method | Description |

|---|---|

| Analytical | Uses formulas for precise calculations. |

| Computational | Simulates scenarios for testing tooth pitch options. |

Choosing the right method can boost efficiency and save time. So, why not play with these optimizations and make your milling experience sharper and more fun?

Impact of Tooth Pitch on Productivity and Tool Life

Analysis of productivity gains with optimized tooth pitch. Case studies showcasing tool life improvement.Choosing the right tooth pitch greatly affects how well a milling cutter works. An optimized tooth pitch can allow machines to cut faster and more smoothly. This can lead to higher productivity, often by up to 20%.

Case studies show that tools with the right tooth pitch last longer, too. Users report improvements in tool life by around 15%. This means less time spent on replacing tools and more time cutting efficiently.

How does tooth pitch optimization improve tool life?

Optimizing tooth pitch leads to better cutting performance, reducing wear and tear on tools. This increases their lifespan.

- Increased production speed

- Longer-lasting tools

- Cost savings on replacements

Milling Cutter Design Considerations

Design adjustments for specific applications. Balancing tooth pitch with other design parameters.Choosing the right design for a milling cutter is key. Each project needs a unique setup. Design adjustments can make a big difference. Here are some important points:

- Tailor your cutter for specific materials.

- Ensure the tooth pitch is balanced with cutting speed.

- Check how heat affects performance.

These adjustments help create effective and efficient tools. Smart design leads to better results in machining tasks. A little tweak can go a long way!

Why is tooth pitch important?

The tooth pitch of a milling cutter influences how well it cuts. It affects the cutting edge’s engagement with the material. A proper pitch can improve precision and reduce wear.

Industry Best Practices for Milling Cutter Tooth Pitch

Recommended guidelines for manufacturers. Common pitfalls to avoid in tooth pitch development.Manufacturers need to follow some smart guidelines for milling cutter tooth pitch. Start by keeping the tooth design simple. Test different pitches for better results. Avoid common mistakes, too. These include:

- Using uneven pitches, which can cause uneven cuts.

- Ignoring blade material, affecting strength and durability.

- Not adjusting for different materials being cut.

Staying aware of these tips can help avoid problems and improve performance.

What are the best practices for milling cutter tooth pitch?

Best practices include using adjustable pitches, testing designs regularly, and choosing the right materials. Regular checks can lead to better cuts and longer tool life.

Future Trends in Milling Cutter Tooth Pitch Optimization

Innovations in milling cutter technology. The role of AI and machine learning in optimization practices.The world of milling cutters is getting a fun upgrade! With new tech, we can expect sharper and smarter tools. Innovations keep popping up, making them more precise and effective, almost like magic! AI and machine learning are now best friends with milling cutter optimization. These technologies help find the best tooth pitch. It’s like having a super-smart assistant that knows exactly what you need. Soon, each cutter will be tailored for its job, taking things to a whole new level!

| Trend | Description |

|---|---|

| Smart Cutters | Tools that learn from each use and improve over time. |

| AI Integration | Using AI to determine the best tooth pitch for any job. |

| Eco-Friendly Designs | Creating cutters that are good for both machines and the planet! |

Conclusion

In summary, optimizing milling cutter tooth pitch helps improve cutting efficiency and product quality. You learn to balance speed and finish. Experimenting with different pitches can enhance your results. We encourage you to explore more resources or practice on your own. Understanding tooth pitch can make you a better machinist or engineer. Keep learning and refining your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Tooth Pitch Optimization:Sure! Here are five questions about milling cutter tooth pitch optimization: 1. Why do we care about tooth pitch? 2. How does tooth pitch change cutting speed? 3. What happens if the tooth pitch is too big? 4. Can different materials change tooth pitch needs? 5. How can we find the best tooth pitch for our work? These questions help us understand how to use milling cutters better!

Sure! Please ask your question, and I’ll do my best to help you.

What Factors Influence The Optimal Tooth Pitch For Milling Cutters In Various Machining Applications?The best tooth pitch for milling cutters depends on a few things. First, it matters what material we are cutting. Hard materials need a different tooth pitch than soft ones. Second, the speed of the cutter affects the pitch too. Faster cutting often needs finer teeth for better results. Lastly, we consider the type of finish we want – smooth or rough. These factors help us decide the best tooth pitch for our job.

How Does Tooth Pitch Affect The Cutting Efficiency And Surface Finish Quality In Milling Operations?Tooth pitch is the space between the teeth on a cutting tool. When tooth pitch is wider, the tool removes more material quickly. This can be good for cutting fast, but it may leave rough surfaces. Closer teeth make cleaner cuts, which improves the surface quality. So, the right tooth pitch helps you balance speed and smoothness in your work.

What Techniques Or Tools Can Be Used To Analyze And Simulate The Performance Of Different Tooth Pitches In Milling Cutters?To study how different tooth pitches work in milling cutters, we can use special computer programs. These programs help us create models to see how the cutters will act. We can also do real tests with the cutters to watch what happens. By comparing the results from both, we can find out which tooth pitch is best for cutting.

How Can Adjustments In Tooth Pitch Improve Chip Removal And Reduce Vibrations During The Milling Process?Adjusting the tooth pitch means changing how the teeth on a cutting tool are spaced. When we do this, it helps cut through materials more smoothly. This makes it easier for chips, which are the tiny pieces that come off the material, to get removed. With better chip removal, the tool doesn’t shake as much. So, we can work faster and make better pieces without as many vibrations.

What Role Does Tooth Pitch Play In The Overall Tool Life And Wear Patterns Of Milling Cutters In High-Speed Machining Environments?Tooth pitch is the distance between the teeth on a milling cutter. It affects how the tool cuts and how long it lasts. If the pitch is too close, the tool can wear out faster. With the right tooth pitch, the cutter stays sharper longer and works better. So, choosing the right tooth pitch helps keep our tools in good shape during high-speed work.