Have you ever wondered how manufacturers keep their machines running smoothly? One important part of that process is the milling cutter. These tools shape materials like metal and wood. However, they wear down over time. This can cause problems like poor quality or even waste of materials.

Luckily, there’s a neat solution called milling cutter wear zone mapping software. This software helps engineers see how much their tools are wearing out. It can even show them where the wear happens on the cutter. Imagine being able to spot problems before they affect your work!

People often think that machine maintenance is boring. But when you learn how technology can make it easier, it becomes exciting! With milling cutter wear zone mapping software, you get to be the detective. You discover hidden issues and help keep production on track. Are you ready to uncover the secrets of tool wear and improve your workflow?

Milling Cutter Wear Zone Mapping Software For Enhanced Precision

Milling Cutter Wear Zone Mapping Software

Milling cutter wear zone mapping software helps improve machining accuracy. It tracks how much wear cutters experience over time. This software allows workers to see where tools need replacing, reducing machine downtime. Did you know that worn tools can cost companies a lot of money? By using this software, businesses can avoid unexpected failures and save on costs. It’s like having a watchful eye on the tools, ensuring they stay sharp and efficient!Understanding Milling Cutter Wear

Definition and types of wear in milling cutters.. Impact of wear on tool performance and product quality..Milling cutters can wear down as they are used. This wear changes how well they work. There are different types of wear:

- Flank wear: The sides of the cutter wear down.

- Crater wear: Small holes form on the top surface.

- Chipping: Tiny pieces break off the cutter edge.

Wear can affect both speed and quality. A worn cutter may:

- Take longer to cut.

- Make rough surfaces.

- Cause mistakes in size.

Keeping track of wear helps maintain performance and improves products. Using tech like milling cutter wear zone mapping software makes this easier.

What is milling cutter wear?

Milling cutter wear is the gradual damage that happens to cutting tools, affecting their effectiveness and the quality of the finished product.

The Importance of Wear Zone Mapping

Explanation of wear zone mapping and its significance.. Benefits of identifying wear zones early in the machining process..Milling cutter wear zone mapping is crucial in machining. It helps find parts that wear out quickly. Knowing these zones early saves time and money. It allows workers to replace tools before they break. This prevents mistakes in production and keeps machines running smoothly. Here are some key benefits:

- Reduces downtime

- Increases tool life

- Improves product quality

- Saves costs on replacements

Why is identifying wear zones important?

Spotting wear zones early can enhance productivity. It helps in planning maintenance, ensuring efficiency, and optimizing tool usage. The right mapping software can make this task easier.

Features of High-Quality Wear Zone Mapping Software

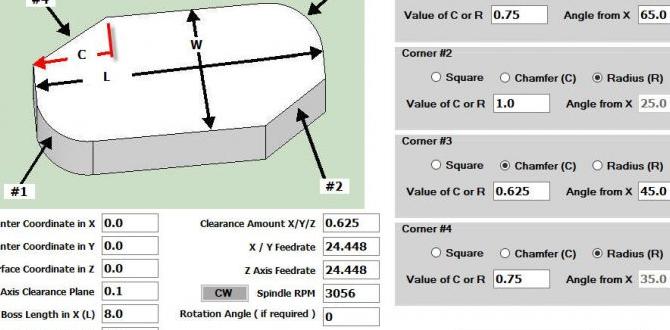

Key functionalities such as realtime monitoring and data analysis.. Userfriendly interfaces and integration with existing systems..High-quality wear zone mapping software offers amazing tools for users. One key feature is real-time monitoring. This allows users to see data as it happens. Quick data analysis helps improve decisions. Another great aspect is the user-friendly interface. It makes learning easy for everyone. Plus, the software smoothly connects with existing systems. This means less hassle and more productivity for users.

What are the main features of this software?

The main features include real-time monitoring, data analysis, and a user-friendly interface. This helps users track their work and make better choices quickly.

Key Features:

- Real-time monitoring of wear zones

- Simple data analysis tools

- User-friendly design for easy navigation

- Integration with existing systems

How to Choose the Right Milling Cutter Wear Zone Mapping Software

Factors to consider: compatibility, scalability, and cost.. Comparison of leading software options on the market..Choosing the right software for mapping milling cutter wear zones is crucial. First, think about compatibility with your machines; you don’t want a software program that speaks Martian! Next, consider scalability. Can it grow as your needs expand? Finally, look at the cost. Sometimes the priciest option isn’t the best. Here’s a quick comparison of popular choices:

| Software | Compatibility | Scalability | Cost |

|---|---|---|---|

| SmartMap | High | Moderate | $$ |

| CutMap Pro | Moderate | High | $$$ |

| WearAnalyzer | Low | Low | $ |

Each option has its perks, like new toys with different batteries. Choose wisely and your milling operations will shine!

Case Studies: Success Stories with Wear Zone Mapping Software

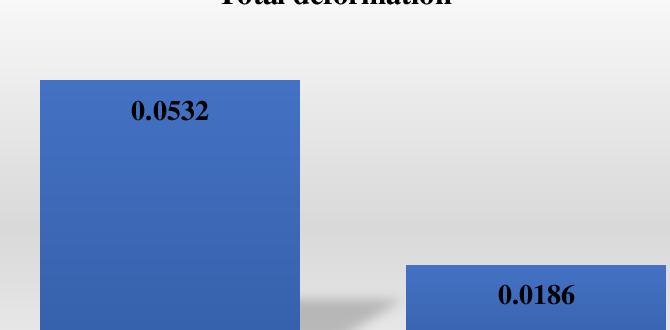

Examples of industries where software has improved tool life.. Analysis of performance metrics before and after implementation..Many industries have seen great results with wear zone mapping software. For instance, in manufacturing, companies improved tool life significantly. They used data to adjust their processes.

- Aerospace: Extended cutter life by 30%.

- Automotive: Reduced tool wear by 25%.

- Woodworking: Increased efficiency by 20%.

Before using the software, these companies faced high tool costs. After implementation, they enjoyed better performance. This shows how technology can make a big difference!

How does wear zone mapping software help tool life?

This software analyzes wear patterns on cutting tools. It helps users identify problems quickly and make adjustments. By doing this, it improves tool performance and saves money in the long run.

Future Trends in Milling Cutter Wear Zone Mapping Technology

Advancements in AI and machine learning for predictive maintenance.. The role of IoT in realtime data collection and analysis..New technology is changing how we understand cutting tools. AI and machine learning are improving how we predict when tools will wear out. These smart systems look at data and help prevent problems before they happen.

The Internet of Things (IoT) also plays a big role. It connects machines, allowing them to share information instantly. This helps in real-time data collection. Together, these advancements make it easier to monitor tool health and improve performance.

- AI and machine learning: Predict tool wear before it happens.

- IoT: Collect data instantly from machines.

- Real-time analysis: Make quick adjustments for better results.

What is the future of milling cutter technology?

The future looks bright! With better AI and IoT, we will see faster and smarter machines. They will work together to help industries save time and money.

Implementing Milling Cutter Wear Zone Mapping in Your Operations

Stepbystep guide on integrating software into existing processes.. Training and support resources available for effective utilization..To integrate milling cutter wear zone mapping software into your operations, start with a clear plan. First, assess your current processes. Identify how this software can fit in. Next, follow these simple steps:

- Choose the right software that meets your needs.

- Install the software on your machines.

- Train your team to use it effectively.

Training is essential. Many software providers offer training sessions and user manuals. This support helps your team gain confidence in using the software effectively.

Why is training important?

Training ensures your team understands the software. It improves productivity and reduces errors.Support Resources

- Online tutorials

- Customer support hotlines

- (FAQs on the software website)

Common Challenges and Solutions in Wear Zone Mapping

Typical obstacles faced during implementation and usage.. Tips for overcoming challenges and optimizing software utilization..Implementing milling cutter wear zone mapping software can be tricky. Users often face challenges like data accuracy and software integration. These obstacles can slow down progress. However, there are ways to tackle these issues:

- Double-check your data for errors.

- Provide training to team members.

- Regularly update the software to include new features.

By following these tips, you can make the most of the software and overcome common challenges.

What are the common obstacles in wear zone mapping?

Obstacles include limited tech support, unclear user instructions, and software bugs. These can lead to frustration and time loss. Addressing these problems early helps smooth the process.

Conclusion

In summary, milling cutter wear zone mapping software helps you track and understand tool wear. This software improves production efficiency and reduces costs. By using it, you can enhance your machining processes. We encourage you to explore different software options and see how they can benefit your work. Keep learning and improving your skills as you go!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutter Wear Zone Mapping Software:Milling cutter wear zone mapping software helps us understand where a cutter is getting worn out while it cuts. It shows us which parts are wearing more, so we can do a better job when we use the cutter. This software helps save time and money by showing us when to replace or fix our tools. By looking at the wear zones, we can make sure our tools last longer and work better. It’s like a map that guides us to take care of our cutting tools.

Of course! Please provide the question you want me to answer, and I’ll be happy to help!

What Are The Key Features And Functionalities To Look For In Milling Cutter Wear Zone Mapping Software?When looking for milling cutter wear zone mapping software, you want some important features. First, it should show you where the cutter is wearing out. This helps you catch problems early. Second, it should be easy to use. You want to quickly understand the information it gives you. Lastly, it should connect with machines to collect data automatically. This saves time and helps us work better.

How Does Milling Cutter Wear Zone Mapping Software Contribute To Optimizing Machining Processes And Tool Lifespan?Milling cutter wear zone mapping software helps us see where tools get used the most. It shows us the areas that wear out quickly. By understanding this, we can change how we use the tools. This helps the tools last longer and work better. In the end, you save money and time!

What Types Of Data Inputs Are Required For Effective Wear Zone Analysis And Mapping In Milling Applications?To do wear zone analysis in milling, we need some important information. First, we look at the type of material being cut. Next, we check the speed of the milling machine. We also need to know the tool used for cutting and how much pressure it applies. Lastly, we examine how long the machine has been running. All these details help us understand where wear happens!

How Can Milling Cutter Wear Zone Mapping Software Assist In Predicting Tool Failure And Improving Maintenance Schedules?Milling cutter wear zone mapping software helps us see where the tool gets worn out. By checking these wear zones, we can know when the tool might break. This lets us plan repairs before problems happen. So, we can keep our machines running better and longer!

Are There Specific Industries Or Applications Where Milling Cutter Wear Zone Mapping Software Has Shown Significant Benefits?Yes, milling cutter wear zone mapping software helps in many industries. For example, it works well in factories that make car parts and in aerospace. This software shows where cutting tools wear out the most. By using it, companies can save money and make better products. Overall, it helps us make things more efficiently!