Have you ever wondered how some tools seem to know exactly what to do? Imagine a milling cutter that not only cuts but also learns from its actions. This is the power of milling cutters equipped with intelligent feedback systems. These advanced tools can make our work easier and more efficient.

Picture this: you’re using a milling cutter, and it starts to notice tiny changes. Maybe the material is a bit different today. With intelligent feedback, it adjusts itself in real-time, ensuring a perfect cut every time. Isn’t that amazing?

These intelligent systems help reduce mistakes and save time. They can even predict wear and tear. This means less downtime and more productivity. As you read on, you’ll discover how these innovations are changing the way we think about milling tools.

Milling Cutter With Intelligent Feedback Systems: Enhancing Precision Output

Milling cutters equipped with intelligent feedback systems enhance precision in machining. These advanced tools sense and adjust to changing conditions during the cutting process. Imagine a cutter that learns and improves, making your work easier and faster! With real-time feedback, users can minimize waste and improve product quality. Did you know that smart milling technology can even predict potential issues before they happen? This innovation not only boosts efficiency but also saves time and resources in manufacturing.

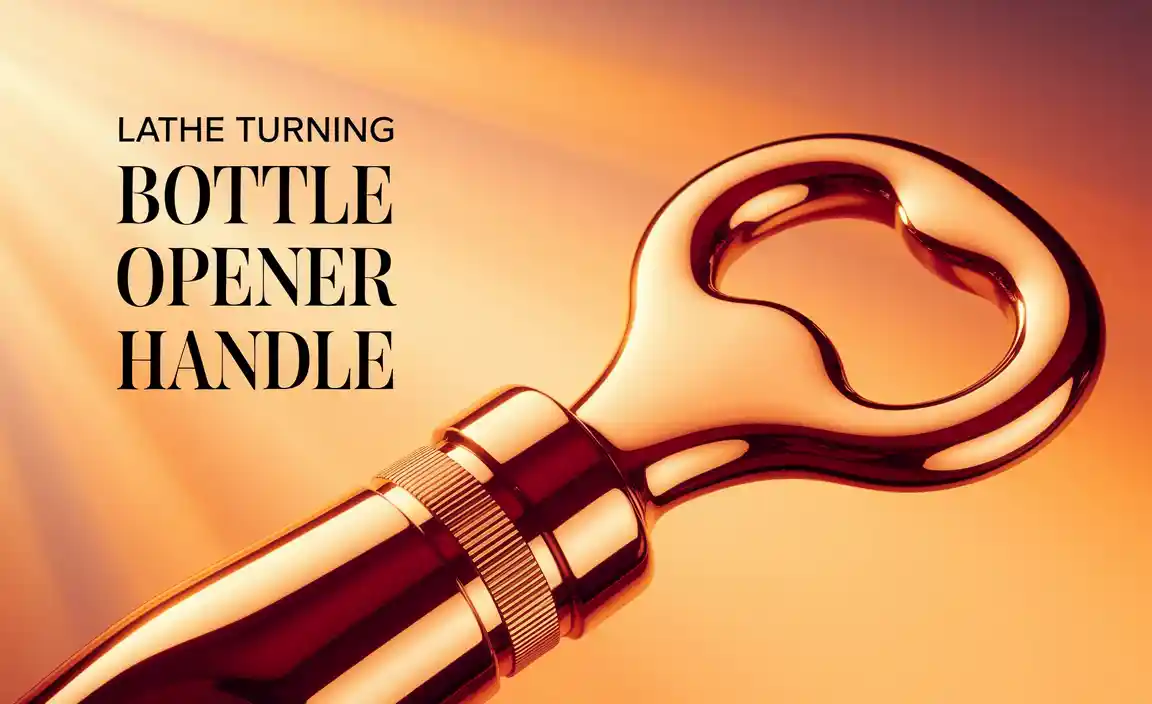

What is a Milling Cutter?

Definition andFunctionality. Types of Milling Cutters Available.

A milling cutter is a tool used to shape and cut materials like metal and wood. It works by spinning rapidly to slice through these materials, creating smooth surfaces or specific shapes. There are several types of milling cutters, each designed for different tasks. Some popular types include:

- Face Cutters: Great for flat surfaces.

- End Mills: Perfect for making pockets and curves.

- Slot Drills: Ideal for creating slots or grooves.

- Ball Nose Cutters: Used for 3D shapes and contours.

These tools are essential in factories and workshops. They help create everything from small parts to large machines, making them incredibly valuable.

What is the purpose of a milling cutter?

The primary purpose of a milling cutter is to shape materials. It does this by removing material with sharp edges. This process helps produce precise parts for various uses.

Common Types of Milling Cutters:

- Face mills

- End mills

- Drill bits

- Slitting saws

How Intelligent Feedback Systems Enhance Milling Cutters

RealTime Monitoring and Data Analysis. Adaptive Control for Optimal Performance.

Intelligent feedback systems work like a coach for milling cutters. They keep an eye on everything in real-time, making adjustments that help perform better. Imagine a milling cutter having its own personal trainer—sounds funny, right? But that’s how it does its job! The system can analyze data instantly and change settings as needed. This ensures the cutter is always in top shape, carving through materials smoothly. It’s like having a smart robot buddy!

| Feature | Benefit |

|---|---|

| Real-Time Monitoring | Helps catch problems before they become big headaches. |

| Data Analysis | Provides insights for better decision-making. |

| Adaptive Control | Optimizes cutting performance continuously. |

Key Technologies Behind Intelligent Feedback Systems

Sensor Technologies Used in Modern Milling Cutters. Integration of AI and Machine Learning in Feedback Systems.

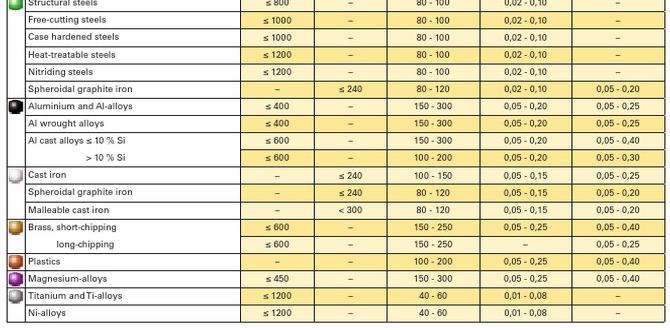

Modern milling cutters use various sensor technologies. These sensors help machines understand the cutting process better. They can detect changes in pressure, temperature, and vibration. This information is vital for making adjustments.

AI and machine learning are also crucial. They analyze data from sensors in real-time. By learning from past data, they can predict issues before they happen. This means more precise and efficient cutting. It leads to better results and less waste.

What sensors are important for milling cutters?

Pressure sensors, temperature sensors, and vibration sensors are key to gathering data for better performance.

- Pressure Sensors: Monitor cutting force.

- Temperature Sensors: Check heat levels.

- Vibration Sensors: Detect machine stability.

Intelligent feedback systems enhance the milling process. They enable machines to be smarter and more efficient. This is important for high-quality production.

Applications of Milling Cutters with Intelligent Feedback Systems

Industries Utilizing Advanced Milling Technology. Case Studies Demonstrating Enhanced Efficiency.

Milling cutters with smart feedback systems are making waves in various industries. From automotive to aerospace, these tools help create parts with amazing accuracy. Imagine a robot chef that knows just how much to chop; that’s how these machines work! Companies using this tech have seen up to a 30% boost in efficiency. Here’s a quick look at some key sectors and how they benefit:

| Industry | Efficiency Improvement |

|---|---|

| Automotive | 25% |

| Aerospace | 30% |

| Healthcare | 20% |

These amazing results show that smarter tools lead to better products. Who wouldn’t want a little extra magic in their machines?

Challenges and Limitations of Intelligent Feedback Systems

Technical Challenges in Implementation. Economic Considerations for Adoption.

Building intelligent feedback systems is like assembling a puzzle. It seems easy, but it has tricky pieces! First, there’s the need for specialized tech. This can lead to high setup costs that might scare off businesses. They may think, “Why spend a fortune when I can stick with my old tools?” Plus, keeping everything updated is another challenge—it’s like getting a new toy every birthday but forgetting to take care of the last one!

| Challenge | Description |

|---|---|

| Technical Complexity | High costs for installation and maintenance |

| Economic Viability | Many may hesitate due to price and uncertainty |

In short, while these systems can boost efficiency, budget worries keep some folks on the edge of their seats. Is it worth it? That’s the million-dollar question!

The Future of Milling Cutters with Intelligent Feedback Systems

Trends Shaping the Future of Precision Machining. Innovations on the Horizon: What to Expect.

Milling cutters are getting smarter with intelligent feedback systems. This means they listen and learn as they work. Exciting trends show how this can improve precision machining. For instance, machines will soon predict errors before they happen. This helps make parts faster and more accurately. Innovations on the horizon include:

- Real-time adjustments for better results.

- Usage of AI for smarter manufacturing.

- Improved safety features for workers.

These changes will shape the future of milling cutters, making manufacturing more efficient and reliable.

What are the main trends in precision machining?

Main trends include better automation, high precision, and using advanced materials for stronger parts.

Conclusion

In conclusion, milling cutters with intelligent feedback systems improve precision and efficiency. They help us make better decisions while cutting materials. By using these advanced tools, you can enhance your projects and save time. If you want to learn more, check out articles on smart tools or visit a local workshop to see them in action!

FAQs

How Do Intelligent Feedback Systems Enhance The Performance And Precision Of Milling Cutters In Manufacturing Processes?

Intelligent feedback systems help milling cutters work better and more accurately. They collect information while the cutter is working. You can think of it like a coach giving tips to a player. This feedback helps the machine make quick adjustments. As a result, the cuts are smoother and more exact, helping us make better products.

What Types Of Sensors Are Commonly Integrated Into Milling Cutters To Facilitate Intelligent Feedback, And How Do They Function?

Milling cutters can have different sensors to help them work better. Some common sensors include temperature sensors and vibration sensors. Temperature sensors check if the cutter gets too hot while working. Vibration sensors watch for any shaking that might mean something is wrong. Together, these sensors help us know how well the cutter is doing its job.

In What Ways Can Real-Time Data From Intelligent Feedback Systems Contribute To Predictive Maintenance For Milling Tools?

Real-time data from intelligent feedback systems helps us watch machines closely. We can see how the milling tools are working right now. If we notice any problems early, we can fix them before they break. This way, we save time and money on repairs. It also helps the tools last longer, which is great for everyone!

How Do Intelligent Feedback Systems Impact The Overall Efficiency And Productivity Of Milling Operations In Comparison To Traditional Methods?

Intelligent feedback systems help milling operations work better and faster. They provide real-time information so we can make quick changes. This means machines can run smoothly without wasting time or materials. In contrast, traditional methods often rely on guesswork, which can lead to mistakes. Overall, using these smart systems helps us get more done with less effort.

What Are The Challenges And Limitations Associated With Implementing Intelligent Feedback Systems In Milling Cutter Technologies?

Implementing smart feedback systems in milling cutter technologies can be tough. First, we may not have enough data to get accurate results. Second, these systems can be expensive to set up. Also, they need special skills to operate and maintain. Finally, machines might not always understand what we want them to do.