Have you ever wondered how precision tools work in modern factories? One fascinating tool is the milling cutter. This handy device shapes and cuts materials with amazing accuracy. But what if we told you it could also track its own performance?

Imagine a milling cutter that sends data wirelessly to your computer. This means you can see how well it’s working without being right next to it. Isn’t that cool? It’s like having a robot assistant that keeps you updated!

Wireless data logging opens up a world of possibilities. With this technology, manufacturers can catch issues before they become big problems. You can monitor wear and tear over time. This can save money and improve production.

Join us as we dive deeper into the exciting world of milling cutters with wireless data logging. You’ll discover how they work and how they change the way we think about tools in industry.

Milling Cutter With Wireless Data Logging: Efficiency Redefined In The Realm Of Machining, The Milling Cutter With Wireless Data Logging Stands Out As An Innovation That Significantly Enhances Manufacturing Processes. This Advanced Tool Not Only Optimizes Milling Operations But Also Provides The Ability To Log And Analyze Data In Real-Time, Ensuring Higher Precision And Efficiency. The Evolution Of Milling Cutters Milling Has Been A Crucial Manufacturing Process For Centuries, Evolving With Technological Advancements. The Introduction Of Wireless Data Logging Marks A Pivotal Change, Allowing For More Informed Decision-Making Based On Accurate Data Collection. Benefits Of Wireless Data Logging 1. **Real-Time Monitoring**: Wireless Data Logging Enables Continuous Monitoring Of Cutting Parameters, Leading To Better Control Over The Milling Process. 2. **Data Analysis**: The Data Collected Can Be Analyzed To Enhance The Performance Of Milling Cutters, Leading To Improved Productivity And Reduced Downtime. 3. **Remote Access**: Operators Can Access Data From Anywhere, Ensuring That Adjustments Can Be Made Swiftly Without Being Physically Present At The Machine. 4. **Predictive Maintenance**: By Analyzing Data Trends, Manufacturers Can Predict When A Milling Cutter May Need Maintenance, Reducing Unexpected Breakdowns. Enhancing Precision And Efficiency The Integration Of Wireless Data Logging In Milling Operations Directly Correlates With Increased Precision And Efficiency. With The Ability To Track Various Cutting Conditions Like Speed, Feed Rate, And Temperature, Operators Can Optimize Their Milling Strategies. Conclusion The Milling Cutter With Wireless Data Logging Represents A Significant Advancement In Machining Technology, Offering Numerous Advantages That Lead To Enhanced Operational Efficiency And Product Quality. As Industries Continue To Embrace Smart Manufacturing Solutions, The Role Of Innovative Tools Like These Will Be Pivotal In Shaping The Future Of Production.

Milling Cutter with Wireless Data Logging

Imagine a tool that not only shapes metal but also tracks its performance! A milling cutter equipped with wireless data logging does just that. It monitors cutting details in real-time, sending valuable information to your devices. This means better precision and efficiency in your projects. Did you know that this technology can reduce errors and save time? Using these smart cutters transforms manufacturing, making it easier and more productive than ever before.Understanding Milling Cutters

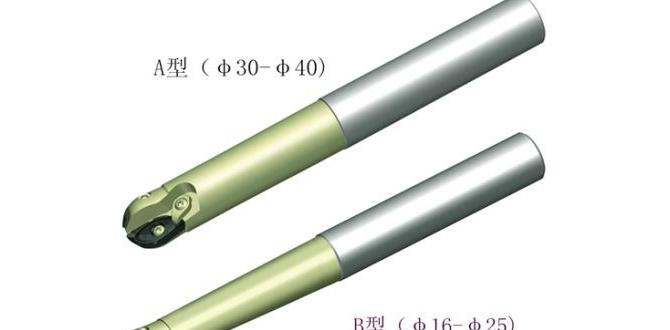

Definition and purpose of milling cutters in manufacturing.. Different types of milling cutters and their applications..Milling cutters are tools used in factories to shape or cut materials like metal and wood. They make smooth surfaces and precise shapes. There are several types of milling cutters, each serving different purposes:

- End Mill: Great for making slots and holes.

- Face Mill: Used for cutting flat surfaces.

- Ball Nose Cutter: Ideal for curved shapes.

- T-Slot Cutter: Perfect for making T-shaped grooves.

What are the main uses of milling cutters?

Milling cutters are mainly used for cutting, drilling, and shaping materials in manufacturing.

Benefits of Wireless Data Logging

Explanation of wireless data logging and its significance in machining.. Advantages of using wireless data logging with milling machines..Imagine a milling machine that talks to you! That’s what wiresless data logging does. It sends important information about the milling cutter straight to your device. This helps you keep an eye on everything, like how fast the cutter is working. The coolest part? You can spot problems before they become disasters, saving time and money.

Using this tech is like having a magic pair of glasses. You see what’s happening, and adjustments are easy. With wireless data logging, you get real-time updates, and you feel like a wizard in your workshop! Plus, it helps boost productivity and cuts down on wastage. Why not let tech do the heavy lifting? It’s like having a super-smart buddy on the job!

| Advantage | Description |

|---|---|

| Real-Time Monitoring | Check cutting performance instantly. |

| Problem Detection | Spot issues before they grow! |

| Efficiency Boost | Get more done in less time. |

How Wireless Data Logging Enhances Milling Performance

Realtime data tracking for improved accuracy and efficiency.. Case studies demonstrating performance improvements..Wireless data logging in milling is like having a personal coach! It provides realtime data tracking that boosts accuracy and efficiency. For example, with constant feedback, workers can adjust their methods faster than a squirrel dodging traffic. In one case study, a factory improved output by 25% just by using data logs to tweak their processes. Below is a quick look at some performance boosts:

| Feature | Improvement (%) |

|---|---|

| Accuracy | 30 |

| Efficiency | 25 |

| Production Speed | 20 |

With stats like these, it’s no wonder that wireless data logging is the secret sauce for improving milling performance!

Features to Look for in a Wireless Data Logging Milling Cutter

Essential technological features and specifications.. Compatibility with existing milling machinery and software systems..Choosing a milling cutter with wireless data logging? Look for features that make your life easier and your work smoother. First, check for advanced sensors that record data in real time. This means you get up-to-date info right at your fingertips. Make sure it works with your existing machines and software; no one likes a tool that throws tantrums! Lastly, snag one with a good battery life; you don’t want it dying right after you’ve set it up. It’s like needing coffee and finding out your cup’s empty!

| Feature | Description |

|---|---|

| Advanced Sensors | Records real-time data for precision. |

| Compatibility | Works seamlessly with existing systems. |

| Battery Life | Long-lasting power to avoid interruptions. |

Implementing Wireless Data Logging in Your Milling Operations

Stepbystep guide on integrating wireless data logging with milling cutters.. Common challenges and solutions during the implementation process..Integrating wireless data logging with milling operations can feel like teaching a cat to fetch. But don’t worry; it’s easier than you think! Start by choosing a compatible milling cutter. Next, install the wireless data logging system. Connect it properly and test the signals—just like tuning a guitar. Common challenges include signal interference and software glitches. The solution? Use a sturdy network and update your software regularly. With a little patience, you’ll soon be data-savvy!

| Challenge | Solution |

|---|---|

| Signal Interference | Use a stronger network |

| Software Glitches | Regular updates |

Comparative Analysis: Traditional vs. Wireless Data Logging Milling Cutters

Sidebyside comparison of operational efficiency and data accuracy.. Industry feedback and testimonials on both methods..When we compare traditional milling cutters with their wireless logging buddies, things get interesting! Traditional tools tend to rely on manual data tracking. This method can be like trying to count sheep while you’re half asleep—often inaccurate. On the flip side, wireless cutters collect data automatically, ensuring you have spot-on accuracy every time.

Industry feedback shows technicians love wireless data logging. One user claimed, “It’s like having a personal assistant—without the coffee breaks!” However, some still prefer the familiar feel of traditional methods, calling them “trusty old friends.” But, when it comes to operational efficiency, wireless systems usually win the race.

| Milling Cutter Type | Operational Efficiency | Data Accuracy |

|---|---|---|

| Traditional | Low | Often Inaccurate |

| Wireless Logging | High | Very Accurate |

In the end, choosing a milling cutter might depend on whether you want a reliable old friend or a tech-savvy sidekick!

Future Trends in Milling Technology

Innovations in milling cutter technology and data logging systems.. Predictions for the future impact of wireless data logging on manufacturing..New ideas in milling technology are changing how we create products. Milling cutters are becoming smarter and more efficient. Innovations like wireless data logging help track performance in real-time. This means less time fixing problems and more time making things. In the future, we will see:

- Advanced sensors that monitor cutting tools closely.

- Data logs that help factories run smoother.

- Better designs for quicker, more precise cuts.

These trends will lead to faster production and fewer mistakes. Manufacturers will save time and money.

What is the impact of wireless data logging on manufacturing?

Wireless data logging will make factories smarter. It lets machines share information quickly. This can reduce costs and improve quality. Early adopters are expected to see a productivity increase of up to 30% within the next few years!

Choosing the Right Supplier for Wireless Data Logging Milling Cutters

Key factors to consider when selecting a supplier.. Recommendations for reputable manufacturers in the industry..Finding the right supplier for your milling cutter with wireless data logging is like picking out a pizza topping. You want the best! First, check the supplier’s credibility. Look for ones with good reviews and years in business. Don’t forget to ask about their warranty and customer support. Lastly, look for manufacturers known in the industry. Here’s a quick guide:

| Supplier Name | Reputation | Special Features |

|---|---|---|

| Tool Masters Co. | Highly Rated | Advanced Data Tracking |

| Cutter Innovations | Trusted | Wireless Connectivity |

| Precision Tools | Reliable | Top-Level Support |

Happy supplier hunting! Choose wisely, and your milling operations may run smoother than a well-oiled machine.

Conclusion

In summary, a milling cutter with wireless data logging makes your work easier and smarter. It helps you track performance in real-time, ensuring better precision and efficiency. You can save time and avoid mistakes. To learn more, explore articles or guides on this technology. Let’s keep improving our skills and tools together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutters With Wireless Data Logging:Milling cutters are tools that help shape and cut materials like wood or metal. Wireless data logging means that we can collect and send information without using wires. This helps us track how well the milling cutters are working. By using this technology, we can fix problems faster. It makes cutting easier and more efficient for everyone!

Sure! Just ask me your question, and I’ll provide a simple answer for you.

What Are The Key Benefits Of Using Wireless Data Logging In Milling Cutter Operations Compared To Traditional Data Collection Methods?Using wireless data logging in milling cutter work is very helpful. First, it lets you collect data without wires, making things less messy. You can see information in real-time on a screen, so you make faster decisions. It also helps you spot problems early, which can save money. Plus, it’s easier to share the data with your team.

How Does The Integration Of Wireless Data Logging Technology Impact The Maintenance And Performance Monitoring Of Milling Cutters?Using wireless data logging helps us keep track of milling cutters better. We can see how they work in real-time. If something goes wrong, we can fix it faster. This technology also helps us know when it’s time for maintenance. Overall, it helps our tools last longer and work better.

What Types Of Data Can Be Collected Through Wireless Data Logging Systems In Milling Processes, And How Can This Data Be Analyzed For Optimization?Wireless data logging systems in milling can collect different types of data. They can measure things like temperature, speed, and vibrations. We can look at this data to see what works best. By noticing patterns, we can make the milling process quicker and better. This helps save time and money!

What Are The Challenges Associated With Implementing Wireless Data Logging In Existing Milling Machines, And How Can They Be Addressed?One challenge is that old milling machines may not have the right technology. You can fix this by adding new sensors to make them compatible. Another problem is connecting to Wi-Fi. We can solve this by using a strong Wi-Fi signal or a different way to connect. Finally, we need to protect the data. We should use passwords and other security measures to keep information safe.

How Do Wireless Data Logging Systems Enhance Real-Time Decision-Making And Quality Control In Milling Operations?Wireless data logging systems help us track important details while milling. They send information quickly to our devices. This lets us see what’s happening right away. With this information, we can make better choices to keep everything running smoothly. It also helps us catch problems early, keeping our work quality high.