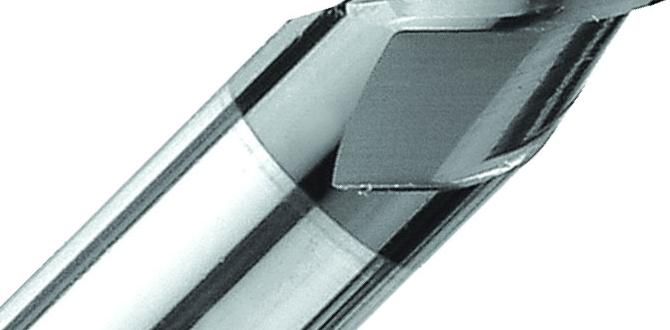

Have you ever wondered how tools can cut through the toughest materials? One amazing tool that does just that is the milling cutter. These special tools shape and carve materials into usable parts. But not all milling cutters are the same. When it comes to hardened steel, you need something extra strong.

Imagine trying to cut a piece of rock with a regular knife. It just won’t work. Milling cutters for hardened steel are like super knives. They can slice through this tough metal with ease.

Here’s a fun fact: hardened steel is not just steel; it’s steel that has been treated to become much stronger. This makes it challenging to machine. Luckily, with the right milling cutters, even hardened steel can be shaped precisely.

So, why do some milling cutters perform better than others? The answer lies in their design and materials. Discovering the right milling cutter for hardened steel can make all the difference in your projects.

Milling Cutters For Hardened Steel: Choosing The Best Tools

Milling Cutters for Hardened Steel

Milling cutters for hardened steel are essential tools in machining. They help shape and cut tough metal surfaces effectively. Did you know that using the right cutter can extend your tool life significantly? High-speed steel and carbide cutters are popular for their strength. Choosing the right angle and size is crucial, as it affects the cutting efficiency. Want to achieve smoother finishes? The right milling cutter makes all the difference!Important Features to Consider

Hardness and material composition of the cutter. Geometry and cutting edge design for optimal performance.Choosing the right milling cutter for hardened steel is important. Consider the following key features:

- Hardness and material composition: Select cutters made from tough materials like carbide for durability.

- Geometry and cutting edge design: Look for shapes that help the cutter stay sharp and cut efficiently. A well-designed edge reduces friction and improves performance.

These features help ensure smooth and effective milling.

What should I know about milling cutters for hardened steel?

Look for cutters that are made from strong materials and have sharp edges. This makes cutting easier and faster.

Recommended Brands and Models

Top brands known for highquality milling cutters for hardened steel. Specific models with user reviews and ratings.Several brands offer excellent milling cutters for hardened steel. Here are some top-rated ones:

- Harvey Tool: Known for precision cutting tools. Users love their performance.

- Gorilla Mill: Praised for durability. Many reviews highlight its long-lasting quality.

- Carbide Processors: Offers a variety of models. Customers appreciate their effectiveness.

These brands focus on quality. Their products receive high ratings from users, ensuring a good choice for your needs.

Applications of Milling Cutters in Hardened Steel Machining

Common industries using these cutters: automotive, aerospace, and manufacturing. Specific machining processes where hardened steel is typically used.Milling cutters are superheroes in the world of machines! They rescue hardened steel in industries like automotive, aerospace, and manufacturing. These cutters slice through tough materials, making critical parts like engine blocks and gears. In automotive, they shape precision components. Aerospace uses them for lightweight structures. Manufacturing relies on them for creating everything from tools to machinery. It’s like a dance of metal and cutter!

| Industry | Application |

|---|---|

| Automotive | Engine parts, gears |

| Aerospace | Lightweight components |

| Manufacturing | Tools, machinery parts |

Best Practices for Using Milling Cutters on Hardened Steel

Tips for setup and positioning during milling. Recommended cutting speeds and feeds for maximum efficiency.Setting up your milling machine properly makes all the difference. Position the cutter so it bites into the steel at just the right angle. Cutting too fast can lead to a meltdown! For hardened steel, cutting speeds should be around 100-200 surface feet per minute. It’s like finding the sweet spot when making pancakes—too hot, and you burn them.

| Cutting Speed (SFM) | Feed Rate (inches per tooth) |

|---|---|

| 100-200 | 0.005-0.015 |

This setup helps you mill efficiently. Take it slow; don’t rush! Remember, a smooth operator is a happy operator.

Maintaining and Caring for Milling Cutters

Techniques for cleaning and storage to prolong cutter life. Signs of wear and when to replace cutters.Keeping your milling cutters in great shape is the best way to make them last. Start by cleaning them after each use. A soft brush or cloth can remove debris without causing harm. Store them in a dry place, away from moisture, to prevent rust. Look out for signs of wear, like dull edges or unusual vibrations. If your cutter is starting to act like a dull pencil, it’s time to replace it! Regular care can save you money and keep your projects running smoothly.

| Care Tips | Signs of Wear |

|---|---|

| Clean after each use | Dull edges |

| Store in a dry place | Unusual vibrations |

Future Trends in Milling Cutter Technology

Innovations in materials and coatings for enhanced performance. Emerging technologies that may impact milling processes.As technology advances, milling cutter designs continue to evolve. New materials and coatings are becoming stronger and more durable. These innovations help them cut through hardened steel better. Emerging technologies like 3D printing and AI could change how milling processes work. They can make manufacturing faster and more efficient.

What are the future trends in milling cutters?

Some key future trends in milling cutters include:

- More durable coatings that resist wear.

- Special materials that improve cutting speed.

- Smart technology for better precision.

These trends will lead to better performance and increased safety in milling processes.

Conclusion

In summary, milling cutters for hardened steel are essential tools for precise metalworking. They help you shape tough materials easily and improve job quality. When choosing a cutter, consider factors like hardness and coating types. We encourage you to explore different options and read more about specific cutters that suit your projects. By doing so, you’ll enhance your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Cutters For Hardened Steel:Sure! When we want to cut hardened steel, we need special tools called milling cutters. These cutters are made from strong materials like carbide. They help shape and smooth the steel. Using the right cutter makes the job easier and more accurate. It’s important to pick the best tool for the job!

Of course! Please provide the question you would like me to answer.

What Types Of Milling Cutters Are Most Effective For Machining Hardened Steel, And How Do Their Designs Differ From Standard Cutters?When machining hardened steel, we should use special milling cutters made from materials like carbide. These cutters are tougher and sharper than standard ones. They have a different shape that helps them cut through hard metal better. Also, they often have special coatings to make them last longer. This way, you can make clean cuts without breaking the tool!

How Do Coatings On Milling Cutters, Such As Tialn Or Tin, Enhance Their Performance And Longevity When Working With Hardened Steel?Coatings like TiAlN and TiN help milling cutters cut better and last longer. These shiny layers make the cutter harder and help it stay cool while working. When you use them on hardened steel, they reduce friction and wear. This means the tool won’t break down as quickly, saving you time and money. Overall, these coatings help you do your job more easily and efficiently!

What Are The Recommended Cutting Speeds And Feeds For Milling Hardened Steel, And How Do These Parameters Vary With Different Cutter Materials?When milling hardened steel, you should use slower cutting speeds and feeds. This helps the tool last longer. For example, carbide tools can go faster than high-speed steel tools. Always check the tool’s instructions for the best settings for your work!

How Does Tool Geometry, Such As Flute Design And Chip Clearance, Affect The Milling Process And Chip Removal When Cutting Hardened Steel?The shape of the tool, like the flutes, helps push the metal chips away while cutting. When we use the right design, the tool can cut better and faster through hardened steel. Good chip clearance means the chips won’t get stuck, which helps us keep cutting smoothly. If the flute design is poor, the tool can get clogged, and it’s harder to work. So, proper tool shape makes cutting easier and cleaner!

What Maintenance Practices Can Extend The Life Of Milling Cutters Used On Hardened Steel, And How Can Operators Identify When A Cutter Needs To Be Replaced?To make milling cutters last longer, you should keep them clean and well-lubricated. Always check for wear and tear after using them. If you see chips, cracks, or dull edges, it’s time to replace the cutter. Also, avoid pressing too hard when cutting. This helps the cutters stay sharp and work better.