Have you ever wondered how toys or plastic models get their smooth shapes? It all starts with the right tools. One important tool is the milling cutter for soft plastics. These cutters help create different shapes from soft plastic materials, making them a vital part of manufacturing.

Imagine a factory where colorful toys come to life. What if the process is simpler than you think? With the help of milling cutters, workers can easily shape soft plastics into the toys we see on store shelves. This allows for precision and creativity in design.

Did you know that milling cutters can cut shapes that are both simple and complex? They can help create everything from building blocks to intricate designs. Understanding milling cutters for soft plastics could spark your imagination. What will you create with these amazing tools?

Milling Cutters For Soft Plastics: A Complete Guide

Milling Cutters for Soft Plastics

Milling cutters designed for soft plastics are essential tools for precise shaping and cutting. They feature sharp edges that easily slice through materials without causing damage. Do you know that using the right cutter can save time and improve the quality of your project? Popular types include end mills and ball nose cutters, each suited for different tasks. By understanding their unique benefits, you can choose the best milling cutter for your next creative venture.Understanding Soft Plastics

Definition and characteristics of soft plastics. Common applications in various industries.Soft plastics are materials that are flexible and easy to shape. They are often used in everyday products like bags, bottles, and toys! These plastics are usually lightweight and have a nice, smooth feel. Their flexibility makes them perfect for a range of uses, from food containers to parts in machines.

| Characteristics | Common Applications |

|---|---|

| Flexible | Packing materials |

| Lightweight | Toys |

| Durable | Consumer goods |

Many industries, such as packaging and manufacturing, rely on soft plastics for their ease of use. With so many practical applications, you could say soft plastics are like the Swiss Army knives of materials! They fit into so many places in our lives.

Factors to Consider When Choosing Milling Cutters

Material compatibility and performance characteristics. Cutting geometry and its impact on results.Choosing the right milling cutter is like picking a snack. You need the perfect match! First, think about material compatibility. Different plastics need different cutters. Some work better than others. Next, consider cutting geometry. This affects how smooth your finish will be. The wrong angle could lead to a rough mess. To keep things clear, here’s a handy table:

| Material | Recommended Cutter Type | Ideal Cutting Angle |

|---|---|---|

| Soft Plastics | Two-flute cutters | 15°-25° |

| Hard Plastics | Four-flute cutters | 10°-15° |

Remember, the right combination will save you time and frustration. So, choose wisely, and may your plastics be perfectly milled!

Best Practices for Milling Soft Plastics

Recommended speeds and feeds for optimal results. Toolpath strategies to minimize deformation.Choosing the right settings is key for milling soft plastics. Good speeds and feeds help achieve smooth cuts. Start with low speeds around 5,000 to 10,000 RPM. Use a feed rate of 30 to 60 inches per minute. This balance minimizes melting and deformation.

Using smart toolpath strategies is also important. Follow these guidelines:

- Use climb milling to reduce chatter.

- Keep tool motion steady to prevent softening.

- Plan cuts to avoid sharp corners that can crack materials.

What is the best feed rate for milling soft plastics?

The best feed rate is typically between 30 and 60 inches per minute. This range helps keep the material cool and intact.

Top Brands and Models of Milling Cutters

Review of leading manufacturers in the market. Comparative analysis of toprated milling cutter models.Many brands create milling cutters for soft plastics. Popular names include Bosch, Makita, and Dewalt. Each brand offers unique features. Some cutting tools work faster, while others provide a smoother finish. Here’s a quick look:

- Bosch: Known for precision and durability.

- Makita: Offers great designs for easy handling.

- Dewalt: Makes tough and reliable cutters.

Choosing the right milling cutter can be exciting. Think about what you need. Ask yourself: Do you need speed or accuracy? Each model has strengths for different tasks!

What are the top features to look for in milling cutters?

Look for versatility, durability, and ease of use. These features can make a big difference in your projects.

Maintenance and Care for Milling Cutters

Tips for cleaning and storing milling cutters. Preventative measures to prolong cutter lifespan.Keeping your milling cutters clean and safe is important. Start by washing them with warm, soapy water. This removes dirt and prevents rust. Dry them well before storage. Use a soft cloth for drying. Store cutters in a dry place. A drawer or toolbox works well.

- Regularly check for wear and tear.

- Avoid using cutters on hard materials.

- Use proper speeds and feeds during use.

Following these tips can help prolong the life of your milling cutters. They are important tools that can last longer with care.

How do I clean milling cutters?

Clean milling cutters with warm, soapy water and dry them immediately to prevent rust.

Common Issues and Solutions When Milling Soft Plastics

Identifying and troubleshooting common challenges. Best practices for avoiding chips, melts, and surface damage.Milling soft plastics can be tricky, but don’t worry! You can tackle common problems like chips, melts, and surface damage. To help, here are a few tips. First, use the right speed and feed rates. A slow feed can lead to melting—like butter on a hot day! Next, maintain sharp cutting edges to avoid those pesky chips. Regular tool inspection is key. Lastly, keep your workspace cool and clean. Here’s a quick table to summarize the best tips:

| Common Issue | Solution |

|---|---|

| Chips | Use sharp cutters and proper feed rates. |

| Melting | Keep speeds in check and maintain cooling. |

| Surface Damage | Inspect tools regularly and use proper techniques. |

With these best practices, you’re ready to mill soft plastics successfully. So, equip yourself with the right tools and keep those soft plastics happy!

Innovations in Milling Technology for Soft Plastics

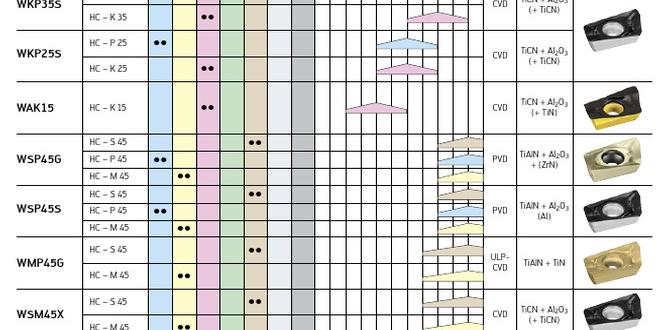

Emerging trends and technologies in milling cutters. Future directions and advancements in cutter design or materials.New tools are changing how we make things from soft plastics. Innovations in milling cutters help make cutting smoother and faster. These new cutters are often made from stronger materials. They can shape plastics better and last longer. Here are some exciting trends:

- Better designs for sharpness and strength

- Use of eco-friendly materials

- Advanced coatings for high performance

In the future, expect even more improvements that make cutting easier!

What are the future directions in milling technology?

Future designs will focus on making tools lighter, stronger, and more efficient. These changes can help cut costs and time in manufacturing.

Conclusion

In conclusion, milling cutters for soft plastics are essential tools for effective machining. They help shape and cut materials easily. Choosing the right cutter increases efficiency and ensures better results. We recommend exploring different types and sizes to find what works best for you. Don’t hesitate to read more about these tools to sharpen your skills in woodworking or crafting!FAQs

Here Are Five Related Questions On The Topic Of Milling Cutters For Soft Plastics:Milling cutters are tools that help shape or cut soft plastics. They spin really fast and can make precise cuts. When we use them, we need to choose the right cutter for the job. This helps in getting clean edges and cool designs. Always wear safety gear to protect yourself while using these tools!

Sure! Please provide the question you would like me to answer.

What Types Of Milling Cutters Are Most Effective For Machining Soft Plastics, And How Do They Differ From Those Used For Harder Materials?For machining soft plastics, you should use sharp end mills or face mills. These cutters have smooth edges, making it easy to slice through soft plastic. They differ from those for harder materials, which are usually tougher and have more teeth. Harder materials need robust cutters to avoid breaking. So, choose the right cutter based on the material you’re working with!

How Can The Choice Of Coating On A Milling Cutter Impact Its Performance When Working With Soft Plastics?The coating on a milling cutter can really change how well it works with soft plastics. A good coating helps the cutter cut smoothly and can last longer. If the coating is too rough or not strong enough, it might wear down quickly or get stuck. So, picking the right coating helps you get better results when you’re cutting soft plastics!

What Are The Recommended Cutting Speeds And Feed Rates When Using Milling Cutters On Soft Plastics To Achieve Optimal Results?When you use milling cutters on soft plastics, you should go slow. A cutting speed of about 100 to 200 feet per minute is good. For feed rates, try 0.005 to 0.020 inches per tooth. This way, you get clean cuts and your plastic won’t melt. Always remember to check how the material reacts while you work.

How Do The Geometrical Features Of Milling Cutters, Such As Flute Design And Helix Angle, Influence Their Efficiency When Milling Soft Plastics?The shape of milling cutters really matters when you’re cutting soft plastics. Flute design helps move the plastic away from the cutter. This keeps the cutter cool and cuts better. The helix angle, or twist of the cutter’s edge, helps it slice smoothly. Together, they make cutting easier and faster for you!

What Common Issues Might Arise When Milling Soft Plastics, And How Can They Be Mitigated Through Cutter Selection And Machining Techniques?When you mill soft plastics, you might see issues like melting, clogging, or rough edges. To fix these, you can use a special cutter with sharp teeth. These cutters help create smooth surfaces. You should also use a lower speed when cutting to prevent heat build-up. Lastly, spraying some coolant can help keep everything cool and working well.