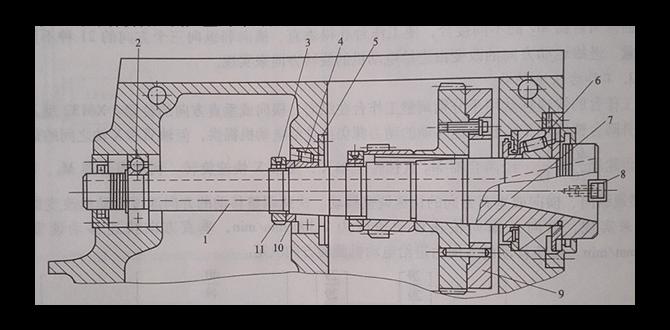

Imagine you have a puzzle. Each piece fits perfectly into another. Now, think about a milling machine. It needs the right collet size, like a puzzle piece, to work best.

Collets hold tools tight, just like your hand holds a pencil. Can you imagine using a pencil that’s too big or too small? It’s almost the same with collets and milling machines. Getting the right size makes everything smooth and easy.

Did you know there are many collet sizes? Each size has a special job. Inventions long ago needed precise tools. Collet sizes can make a big difference, even today.

Let’s dive into the world of collets. Discover how the right size can change everything. Are you ready to learn more?

Understanding Milling Machine Collets Sizes And Types

Milling Machine Collets Sizes

Did you know that collets are like the perfect glove for your milling machine tools? Each size hugs the tool just right, ensuring a firm grip during use. These sizes change based on the job you need to do. Using the wrong collet size can feel like trying to play soccer with a basketball. That’s why understanding collet sizes can help you pick the right fit for smooth and precise milling every time.Understanding Milling Machine Collets

Definition and purpose of collets in milling machines. Importance of choosing the correct collet size for operations.Milling machine collets hold tools in place. They grip bits tightly so they don’t slip. Using the right size is important. Too loose, and the tool slips. Too tight, and it might break. Always pick the correct size for your task. This way, the machine works well and safely. A correct fit ensures precision and quality in milling work.

Why is the right collet size important?

Choosing the correct collet size keeps tools secure and prevents damage. A perfect fit reduces tool wear and enhances performance, ensuring the milling machine operates efficiently.

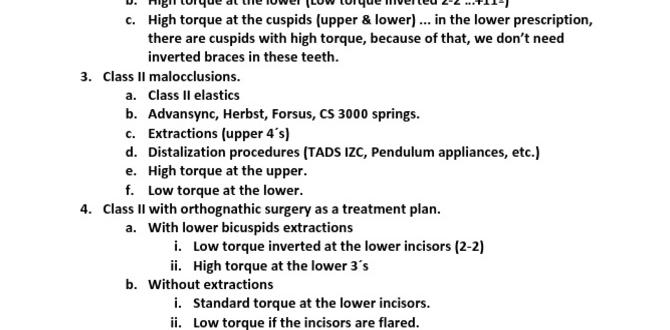

| Collet Size | Fits Tool Diameter |

|---|---|

| 1/4 inch | 0.25 – 0.26 inch |

| 1/2 inch | 0.50 – 0.51 inch |

| 3/4 inch | 0.75 – 0.76 inch |

Remember to check sizes before each project. Correct collets ensure better accuracy in results. A small change in size can make a big difference in work quality and safety.

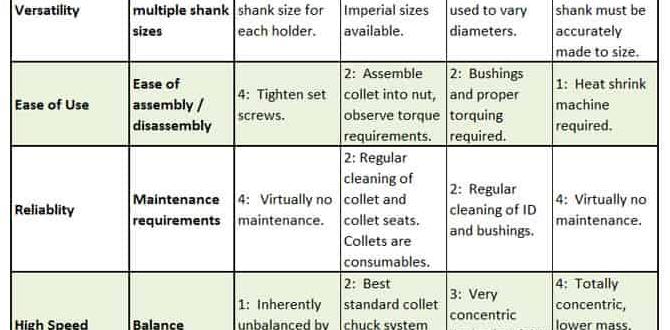

Factors Influencing Collet Size Selection

Material type and its impact on collet size choice. Influence of spindle size and tool diameter on collet selection.Choosing the right collet size is like finding the perfect hat. The material type plays a crucial role here. Softer materials need different collets compared to hard metals. Imagine using a giant hat on a baby; it would look funny! Your spindle size and tool diameter also matter. A bigger spindle needs a bigger collet, like fitting a basketball into a beach ball. Here’s a little cheat sheet:

| Material | Collet Size |

|---|---|

| Softwood | Small |

| Metal | Large |

Remember, a snug fit ensures a happy and efficient milling experience. As someone wisely said, “A well-fitted tool is half the work done!”

Measuring and Identifying Correct Collet Sizes

Techniques for accurately measuring collet sizes. Tools and instruments used in collet size identification.Finding the right collet size helps your machine work well. To get started, use a caliper or a micrometer. They help measure the collet’s width. Hold the tool against the collet, read the number. It shows you how big the collet is.

- Use a ruler for a quick check.

- Check the number listed on the collet.

These tools make sure you know the exact size, helping you choose the right milling machine collet.

What tools are best for measuring collet sizes?

Calipers and micrometers are ideal. They measure diameter and length quickly and accurately. You can also use rulers for simple checks. Measuring tools like these help ensure you have the correct collet size, preventing mishaps.What if I don’t have these tools?

Check the manufacturer’s guide. It often has sizing information. Use this guide to match the collet accurately. If unsure, a local tool shop can help measure it for you.

Measuring collets avoids mistakes and damage to the machine. Always use the correct size which helps work safely and efficiently.

Benefits of Proper Collet Size in Milling Operations

Impact on machining precision and efficiency. Enhanced tool life and reduced wear and tear.How does the right collet size affect milling precision and efficiency?

Proper collet size ensures the machine’s tool holds tight. This leads to precise cuts. When a tool doesn’t wiggle, it shapes materials better. It cuts with less effort, saving energy.Benefits:

- Accurate machining

- Faster operations

Choosing the correct collet size in milling operations is essential. It helps in making work efficient and accurate. When tools fit right, they work with more precision. This reduces time and effort. It also keeps the machine running better for longer. Accurately sized collets lessen wear and tear on tools. This way, companies save money by needing fewer replacements.

Common Mistakes in Collet Size Selection

Misconceptions and errors leading to improper sizing. Solutions and tips for avoiding common selection pitfalls.Choosing the right collet size might seem simple, but it’s a trap for many! A common blunder is mixing up metric and inch sizes, which is a bit like wearing mismatched socks—uncomfortable and awkward. Another mistake? Assuming one size fits all. Spoiler alert: it doesn’t! To avoid these hiccups, always double-check measurements and use sizing charts. Keep a cheat sheet handy to compare different sizes for various tools. Remember, a well-fitted collet ensures smooth operations.

| Collet Type | Common Misstep | Solution |

|---|---|---|

| Inch | Used in place of metric | Check tool specs for correct type |

| Metric | Confused with inch sizes | Use a conversion chart |

Maintenance and Care for Milling Machine Collets

Best practices for maintaining collet integrity over time. Cleaning and storage tips to extend collet lifespan.Collets need love too! Keeping them in tip-top shape makes your milling machine way happier. Brush off chips and dust after each use because they don’t like being dirty. Wipe them down with a bit of machine oil. It’s like giving them a spa treatment! Store them in a dry spot away from any sneaky rust monsters. If you have loads of collets, you’re not alone! Check out this handy table:

| Type | Storage Tips |

|---|---|

| Spring Collet | Use trays with foam padding |

| Milling Machine Collet | Keep in a moisture-free box |

Moral of the story? Loved collets last longer! Remember, a happy collet means a happy machine. Clean them and store them well so they can live their best collet life. Keep it simple, and even your grandma will agree with this wisdom: “A clean collet is a happy collet!” Taking these steps will ensure your collets work better and last longer. Don’t let them turn into grumpy, rusty guys!

Innovations and Trends in Collet Technology

Recent advancements in collet design and materials. Emerging trends influencing future collet selections.Collet technology is giving a thumbs-up for creativity! Imagine collets that can dance because they’re made from materials like carbon fiber and titanium. They’re lighter and stronger, which means they can hug the tools tighter than a grandma would. What’s the buzz? It’s all about eco-friendly innovations and smart designs helping us make cool stuff faster. Oh, did you know fancy coatings can extend a collet’s life?

Here’s a cool table to keep you on track:

| Advancement | Impact |

|---|---|

| New Materials | Enhanced durability and reduced weight |

| Smart Designs | Efficiency and better tool grip |

| Eco-Friendly Trends | Less waste, more smiles! |

Future trends look thrilling, with modular designs and adjustable sizes making choices as easy as pie! So, if you’re wondering what keeps the world of collets racing into the future, even robots might pop their gears with excitement!

Conclusion

Milling machine collet sizes are crucial for holding tools securely. They fit various tool shanks, so knowing the right size is important. When you choose the correct collet size, your machining is safer and more precise. To improve your skills, explore more about collet types and uses. Remember, practice makes perfect in milling work!FAQs

What Are The Standard Collet Sizes Used In Milling Machines, And How Do They Differ Based On The Type Of Machine Or Tooling Used?In milling machines, collets hold tools tightly. They come in sizes like ER32 or ER16. Think of ER as “Elastic Reamer.” These sizes tell us how big of a tool you can hold. Different machines use different collet sizes because they need different tool sizes. So, you can pick the one that fits your machine and tool best.

How Do You Select The Appropriate Collet Size For A Specific Milling Operation, And What Factors Should Be Considered In This Decision?To pick the right collet size for a milling job, match it to the tool’s size. Check the tool’s diameter, which is how wide it is, and choose a collet that fits snugly. Think about how strong the tool needs to be held so it doesn’t wobble. Make sure everything is tight and safe before starting.

How Do Er Collets Compare To R8 Collets In Terms Of Clamping Force And Usability In Milling Machines?ER collets and R8 collets help hold tools in milling machines. ER collets have a stronger grip, which means they hold tools tighter. This makes them good when precision is important. R8 collets are easier to use because you can switch tools quickly. However, they don’t hold as tightly as ER collets.

Can You Explain The Process Of Measuring A Milling Machine Collet To Ensure Proper Fitment And Compatibility With The Spindle?To measure a milling machine collet, first, find its diameter with a ruler or tape measure. This tells you if it fits the spindle, which is the part that turns the tools. Check the length, too, because it should not be too long or short. Make sure the collet is clean and not damaged. This way, everything fits and works well together.

What Are The Potential Consequences Of Using An Incorrectly Sized Collet In A Milling Machine, And How Can These Issues Be Mitigated?Using the wrong-sized collet in a milling machine can cause some problems. The tool might become loose and fly off, which is dangerous. It may also cause the machine to break. To fix these issues, be sure to choose a collet that fits perfectly. Double-check its size before you start the machine.