Imagine building a wooden toy car. You want the wheels to turn smoothly, right? Milling machines work the same way. They cut and shape metal parts, but they need help too. Have you ever thought about what makes this happen safely?

Coolant is like the secret helper for milling machines. It keeps things cool and stops overheating. Without it, machines can get too hot and tired. Choosing the right milling machine coolant is important. Why, you ask? It makes machines last longer and work better.

Did you know that using the wrong coolant is like trying to ride a bike without oiling the chain? Things can go wrong quickly. In our story, you will discover how choosing the right coolant can change everything. Let’s open the box of secrets and learn more!

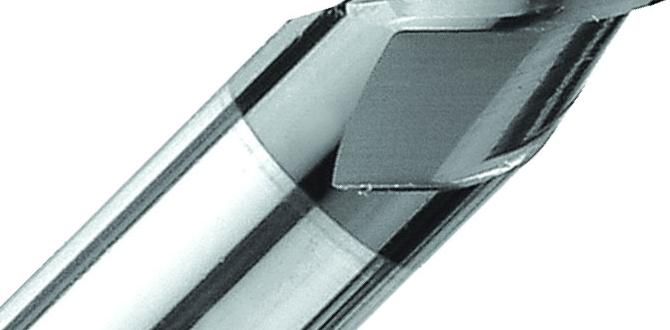

The Ultimate Guide To Milling Machine Coolant Selection Selecting The Right Coolant For Your Milling Machine Is Crucial To Ensuring Optimal Performance And Extending The Life Of Your Tools. Coolants Serve Several Essential Functions, Including Reducing Heat Generated By Friction, Minimizing Tool Wear, And Improving Surface Finish. With Various Types Of Coolants Available, Choosing The Appropriate One Can Be Daunting. This Guide Aims To Simplify The Process Of Milling Machine Coolant Selection By Discussing Essential Factors And Considerations. Types Of Coolants There Are Primarily Three Types Of Coolants Used In Milling Machines: Soluble Oil, Synthetic, And Semi-Synthetic Coolants. 1. **Soluble Oil:** These Are Highly Versatile And Generally Offer Excellent Lubrication And Cooling Properties. They Are A Mix Of Oil And Water And Are Suitable For A Wide Range Of Applications. 2. **Synthetic Coolants:** Made From Chemical Compounds, These Coolants Provide Superior Cooling And Contain Minimal To No Oil. They Are Ideal For High-Speed Machining Processes Where Heat Dissipation Is Critical. 3. **Semi-Synthetic Coolants:** Combining Elements Of Both Soluble Oils And Synthetic Coolants, Semi-Synthetics Offer A Balance Between Lubrication And Cooling. They Are Effective In Preventing Rust And Ensuring Tool Longevity. Selecting The Right Coolant Consider The Following Factors When Choosing A Coolant For Your Milling Machine: – **Material Of The Workpiece:** Different Materials Require Specific Coolant Properties. For Instance, Harder Materials Like Steel May Need Coolants With High Lubricity, While Softer Materials Like Aluminum Benefit From Coolants With Superior Cooling Properties. – **Machining Operation:** The Type Of Milling Operation, Be It Roughing Or Finishing, Influences Coolant Choice. Finishing Operations May Require Coolants With Finer Lubricating Characteristics To Achieve A High-Quality Surface Finish. – **Tooling And Speed:** High-Speed Machining Necessitates Better Heat Dissipation, Which Synthetic Coolants Can Provide. Conversely, Operations Using High-Pressure Tools Might Benefit From The Lubricity Of Soluble Oils. Environmental And Safety Considerations Beyond Performance, Consider Environmental Impact And Safety: – **Biodegradability:** Choose A Coolant That Is Environmentally Friendly And Easy To Dispose Of Without Causing Harm To The Ecosystem. – **Safety For Operators:** Ensure The Coolant Does Not Emit Harmful Fumes Or Cause Skin Irritation. Coolants With Low Toxicity Are Preferable. Maintenance Of Coolant Regular Maintenance Of Coolant Is Crucial To Maintain Its Effectiveness: – **Concentration Levels:** Regularly Check And Adjust The Concentration Of The Coolant Mix To Ensure Optimal Performance And Reduce Microbial Growth. – **Filtration Systems:** Implement Effective Filtration Systems To Remove Chips And Debris From The Coolant, Thereby Increasing Its Lifespan. By Considering These Factors, Manufacturers Can Optimize Their Milling Processes And Ensure Efficient And Safe Operations. The Right Choice In Coolant Not Only Enhances The Quality Of The Machining But Also Contributes To Cost-Effective Manufacturing Practices.

Milling Machine Coolant Selection

Choosing the right milling machine coolant can feel like picking the perfect ice cream flavor. Coolants help keep the machine and tools from overheating. They also make work smoother and improve tool life. Which type should you choose: oil-based, water-based, or synthetic? Consider your machine’s usage and the materials you’re working with. Some coolants even reduce bad smells in the air. Imagine a quieter, cooler workshop with less risk of burns. That’s the power of the right coolant!Understanding Milling Machine Coolants

Types of Coolants: WaterBased, OilBased, and Synthetic. Role and Importance of Coolants in Milling Operations.Coolants play a big role in helping milling machines work smoothly. They keep the machines from getting too hot. There are different kinds of coolants:

- Water-based: These coolants are mixed with water. They help keep the machine extra cool.

- Oil-based: These are made of oil. They make parts slippery to avoid friction.

- Synthetic: These are special coolants, made from man-made materials. They are very clean and long-lasting.

Coolants are important. They help make milling operations smoother and prevent damage. Without them, machines might stop or break. Coolants act as a shield, protecting both the tools and finished work. This keeps the process fast and safe.

Why are coolants used in milling machines?

Coolants keep machine parts cool, reduce friction, and improve performance. They help in cutting operations and save the machine from overheating. Good coolants can make the machine last longer and work better. Without coolants, the machine might slow down or get jammed.Is water the best coolant for milling?

Water-based coolants are very effective. They remove excess heat well. Yet, they can cause rust if not handled right. They’re great for keeping the machine cool but need care. Got a fun fact? When less heat is produced, machines can work faster. Always remember, a happy machine is a cool machine!Factors to Consider When Selecting Coolant for Milling Machines

Material Compatibility and Chemical Composition. Temperature Control and Stability. Lubrication and Cooling Efficiency. Environmental and Safety Concerns.Picking the right coolant for milling machines is like choosing the best superhero for a mission. First, it should be buddies with the materials. Some coolants don’t get along with certain metals and can cause rust or stains, so check compatibility. Next, look for good chemical composition; it should not mess with the machine’s workings. The coolant must also handle heat like a pro and provide awesome temperature control. It should keep the machine cool and running smoothly, ensuring good lubrication too. Don’t forget about the environment; pick one that’s as friendly as your favorite animal! Avoid harmful chemicals that are unsafe. With these in mind, your milling machine will be in good hands!

| Factor | Consideration |

|---|---|

| Material Compatibility | Avoid reactions that harm materials |

| Temperature Control | Maintain stable and cool operations |

| Lubrication Efficiency | Ensure smooth operation with minimal wear |

| Environmental Safety | Choose eco-friendly and safe coolants |

Did you know? Using the right coolant can even prolong the machine’s life, reduce energy costs, and enhance tool performance!

Performance Features of Various Coolant Types

Coolant Longevity and Maintenance Requirements. Corrosion Protection and Surface Finish Impact. Cost Considerations and Economic Efficiency.Choosing the right coolant is like picking the perfect dance partner. Not all are created equal but each has its own performance flair. Some coolants last long, demanding less maintenance. This means less tinkering, more cutting. Others are champs at fighting rust, ensuring machines stay shiny and smooth. Cost? That’s like deciding between a fancy restaurant or a home-cooked meal. You might pay more upfront, but good coolants save pennies in the long run!

| Feature | Advantage | Consideration |

|---|---|---|

| Longevity | Less frequent changes | Higher initial cost |

| Corrosion Protection | Saves equipment | Some formulas may stain |

| Cost Efficiency | Lower long-term cost | Varies by type |

Effective Coolant Management Practices

Regular Testing and Quality Monitoring Techniques. Best Practices for Coolant Preparation and Disposal. Troubleshooting Common Coolant Problems.Does your milling machine sometimes act like it drank expired milk? Good coolant management can CURE that! Testing it regularly ensures that it performs well, just like a top student. Monitor its quality, because nobody likes yucky coolant. For preparation, mix it responsibly—like making a cake, not a swamp! Dispose of it the right way, too. If problems pop up, remember: it’s probably not haunted, maybe just needs some troubleshooting! Below is a simple guide:

| Task | Why It Matters |

|---|---|

| Regular Testing | Keeps the machine purring like a happy cat. |

| Proper Preparation | Avoids creating a toxic concoction. |

| Troubleshooting | Solves pesky coolant quirks. |

Remember, great machines need great care! Or else, even the bravest machines could misbehave. By following these practices, your milling machine will work better and happier!

Innovative Trends and Developments in Coolant Technology

Advances in EcoFriendly and Biodegradable Coolants. Integration of Nanotechnology for Enhanced Performance. Future Projections and Industry Innovations.Coolant technology is changing fast. Eco-friendly coolants are in, and these are safe for our planet. They also break down easily, which is good for nature. Nanotechnology is another big thing. Nano-coolants work better and keep machines cool for longer. What will come next? Many people think we will see more new, smart ideas that help machines and protect us too.

What are eco-friendly coolants?

Eco-friendly coolants are liquids used to cool machines, and they are safe for the environment. They break down naturally and do not harm plants or animals. This helps keep our world clean.

Expert Tips for Optimizing Milling Operations with the Right Coolant

Recommendations from Industry Professionals. RealWorld Case Studies and Success Stories.How Can Industry Professionals Improve Milling with Coolant Choices?

Experts say choosing the right coolant makes milling better. Successful factories use coolants wisely. They see less wear on tools and smoother cuts.

- Use the right coolant type: Water-based coolants are common. They help in fast cooling.

- Monitor use: Regular checks keep things smooth. Dirt-free coolants lead to better milling.

- Check case studies: Real-world examples show how good coolants can improve results.

What Are Some Real-Life Success Stories with Coolant Choices?

In a small machine shop, one tweak in coolant choice led to faster output. This simple change saved time and money. Another factory used feedback from staff. They switched to a different type, which improved tool life.

Wise choices simplify work and boost savings. Simply altering coolants can help equipment and increase efficiency. Consult with peers and examine instances for wisdom on decisions.

As one industry pro said, “Coolants are small but mighty helpers.”; Their proper application is crucial to success.

Conclusion

Choosing the right milling machine coolant is crucial. It keeps the machine cool, extends tool life, and ensures smooth operation. You should consider the material being milled and coolant type (oil-based or water-soluble). Test different coolants to see what works best for your needs. For more tips, explore resources on machine maintenance and coolant options.FAQs

What Are The Key Factors To Consider When Selecting A Coolant For A Milling Machine To Ensure Optimal Performance And Tool Life?When choosing a coolant for a milling machine, pay attention to a few important things. First, make sure the coolant keeps the machine cool. This helps the machine work better and longer. Next, check if the coolant stops rust on the machine parts. Finally, ensure the coolant is safe for you to use and doesn’t harm your skin or the environment.

How Does The Type Of Material Being Machined Influence The Choice Of Coolant For A Milling Machine?The type of material you are cutting affects the kind of coolant you choose. For soft metals, like aluminum, you need a coolant that won’t stain or cause rust. Hard metals, like steel, might need a stronger coolant to keep things cool and stop the metal from burning. Using the right coolant helps the machine work better and keeps the material safe.

What Are The Differences Between Oil-Based And Water-Based Coolants, And How Do They Affect Milling Machine Operations?Oil-based coolants are like thick, slippery oils that help keep the milling machine parts moving smoothly. Water-based coolants are more like watery liquids that cool things off quickly. Oil-based coolants can make cutting smoother, but they can be messy and harder to clean. Water-based coolants are easier to clean up, but they might not make the machine parts move as smoothly. Both help machines stay cool and work well, just in different ways.

How Do Environmental And Safety Regulations Impact The Selection Of Coolant For Milling Machines In Industrial Settings?When choosing coolant for milling machines, we must follow safety and environmental rules. These rules help keep workers safe and protect the earth. Some coolants might contain chemicals that could harm people or nature. So, we pick coolants that are safe and eco-friendly. This ensures everyone stays healthy and nature stays clean.

What Are The Potential Consequences Of Using An Improper Or Incompatible Coolant In Milling Operations, And How Can These Be Mitigated?If you use the wrong type of coolant in a milling machine, the machine can get really hot. This could break the machine or make it not work properly. It can also cause the part you’re making to look bad or break. We can stop this by always checking we use the right coolant. We should follow the instructions for the machine carefully.