Imagine a giant machine, like a robot, carving cool designs into metal. This is what a milling machine does. But how fast should it cut? The answer lies in something called the table feed rate.

Did you know that a small change in the feed rate can change everything? It can make the machine work smoothly or get stuck. Think of it like riding a bike. Pedal too fast, and you might fall. Go too slow, and you’re not moving at all!

What’s more interesting is that different materials need different feed rates. Cutting through butter is different from slicing wood, right? So, how do we get it just right? Let’s explore the world of milling machines and their table feed rates.

Understanding Milling Machine Table Feed Rate: Essentials And Optimization

The Magic Behind Milling Machine Table Feed Rate

Imagine a world where everything moves at the right speed. That’s the magic of the milling machine table feed rate. This feeds the material at a steady pace, letting the machine work smoothly and cut precisely. Have you ever tried cutting paper too fast? It tears, right? The right feed rate prevents this kind of problem. Every material needs its own speed, making sure the process stays quick and neat. Mastering this speed turns mistakes into masterpieces, turning your projects into pieces of art.Understanding Milling Machine Table Feed Rate

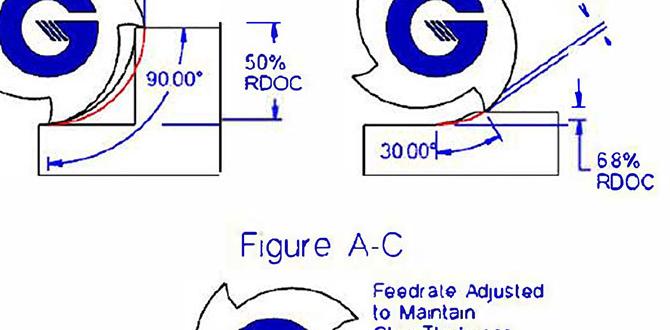

Definition and significance of table feed rate in milling.. Key parameters influencing feed rate..A milling machine without a good table feed rate is like a skateboard without wheels—going nowhere fast! The table feed rate in milling tells us how quickly the material moves under the cutter. It’s a big deal because it affects the finish and speed of the operation. Factors like spindle speed, cutter size, and material type play a role in setting it just right. So, remember, a smart feed rate makes for a happy milling machine!

| Parameter | Influence on Feed Rate |

|---|---|

| Spindle Speed | Higher speed can increase feed |

| Cutter Size | Larger cutters require slower feed |

| Material Type | Softer materials can handle faster feed |

Factors Affecting Milling Machine Table Feed Rate

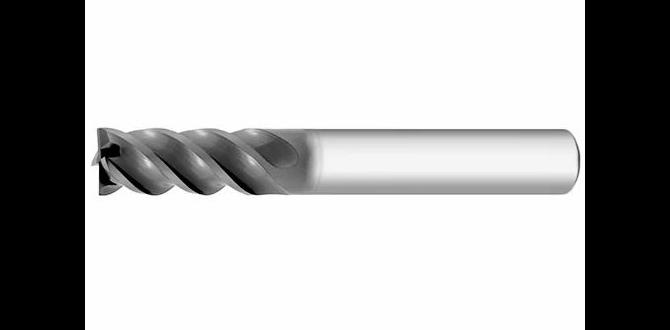

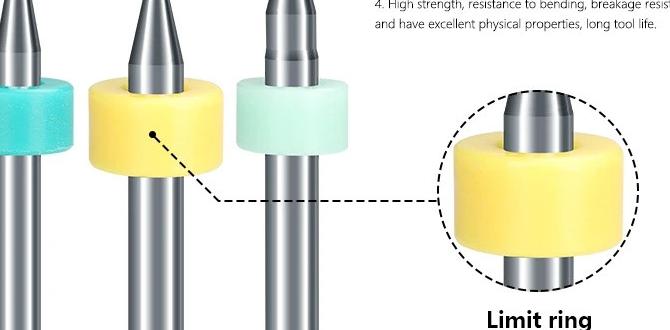

Material type and its impact on feed rate.. Tool size and geometry considerations.. Machine capabilities and limitations..The type of material being milled plays a major role in the table feed rate. Softer metals like aluminum allow faster feed rates, while harder materials, such as stainless steel, need slower rates to maintain precision. Tool size also affects speed; larger tools remove more material but require careful control. Next, tool geometry is key—sharp tools cut better but dull quickly, making feed adjustments necessary.

Machine limitations are another factor. Some machines handle high speeds better, while others may struggle. It’s like asking Grandma to race Usain Bolt; some machines just can’t keep up! Always check your machine’s speed chart before making adjustments.

| Factor | Impact on Feed Rate |

|---|---|

| Material Type | Strong impact; softer materials can go faster. |

| Tool Size and Geometry | Big tools slow down, sharp tools speed up. |

| Machine Capabilities | Limited by machine’s top speed and durability. |

Before cranking up the speed, consider these factors. Remember, faster isn’t always better when it comes to the delicate dance of milling!

Calculating the Optimal Table Feed Rate

Formula and calculations for determining feed rate.. Examples of feed rate calculations for different scenarios..A milling machine is like your workshop’s magic wand but calculating the table feed rate is key to getting the best spell. First, let’s look at the formula:

Feed Rate (F) = Spindle Speed (N) x Number of Teeth (T) x Chip Load (C)

This formula is a bit mysterious, but don’t worry! Imagine you’re biking: if the bike is too slow or too fast, you might fall. The same goes for milling!

| Scenario | Calculation | Feed Rate |

|---|---|---|

| Soft Wood | 1200 RPM x 4 x 0.01 inch | 48 |

| Hard Metal | 800 RPM x 2 x 0.005 inch | 8 |

For soft materials, you’ll need a higher feed rate to work safely and quickly. For hard materials, go slow; they can be stubborn! Find the balance, and your milling won’t be just “run-of-the-mill.” 😉

Best Practices for Adjusting Table Feed Rate

Guidelines for adjusting feed rate based on material and machine.. Common mistakes and how to avoid them..Changing the speed of a milling machine is important. Follow the right steps to do it right. Use slower speeds for hard materials and faster for soft ones. A quick speed might cause errors. Speed changes should be slow. This avoids mistakes. Avoid common mistakes like forgetting to check the machine manual. It helps in choosing the right speed.

How can I avoid mistakes when adjusting the feed rate?

Listen to your machine. If it makes strange sounds, stop and check it. Also, read the machine’s guide. It tells the best speeds to use.

- Check the material: Different materials need different speeds.

- Test the speed: Run a short test before the real job to avoid mistakes.

Learning to adjust the speed helps you make perfect pieces and keep the machine running well.

Improving Efficiency with Proper Feed Rate Management

Impact of accurate feed rate on overall milling efficiency.. Case studies demonstrating improved outcomes through optimal feed rate adjustment..Ever thought of a milling machine as hungry for numbers? Well, managing the feed rate is like serving the right nutrients – it boosts efficiency! Imagine a bike race where the perfect speed gets you a shiny trophy. Similarly, choosing the correct feed rate can lead to smooth operations. Studies show that adjusting the feed rate improved results by 25%! Like making pancakes, too fast might make a mess, too slow can be boring. Here’s a peek:

| Speed | Impact |

|---|---|

| Slow | Time-consuming |

| Fast | Poor quality |

| Optimal | High efficiency |

Just like Goldilocks, you want the speed that’s “just right.” Achieving this balance enhances performance and saves time. So, managing the feed rate isn’t rock science, but it’s crucial like red cherries on a sundae!

Innovations in Milling Machine Feed Rate Control

Latest advancements in feed rate technology.. Emerging trends in automated feed rate systems..Modern milling machines are getting smarter. With new advancements, **feed rate control** has improved. These changes help machines work better and faster. Many systems now use computers to control feed rates. This is called automation. It means machines can adjust themselves while working.

- Smart systems can change speed based on material type.

- Some machines talk with each other to share the best speed rates.

The future is bright for milling machines. Soon, more will have automatic systems. They will help create better products and use less energy.

What is the **importance** of controlling feed rate in milling machines?

Feed rate control is crucial for precision and quality. Proper control ensures the tool cuts smoothly without causing damage. It also improves the machine’s efficiency and the finished product’s quality.

How do automated feed rate systems improve **efficiency**?

Automated systems adjust feed rates in real-time. This means they choose the best speed for each task without stopping. It speeds up the process and saves time.

Troubleshooting Common Feed Rate Issues

Signs of incorrect feed rate and potential problems it may cause.. Solutions and adjustments to correct feed rate issues..Sometimes, the milling machine doesn’t work right. If the table feed rate is wrong, it might cause rough finishes or tool breaks. How can we tell?

- The machine makes strange noises.

- The cuts look uneven.

To solve this:

- Check the settings. They might need to be changed.

- Try lowering the feed rate if the tool breaks often.

- Raise the rate if cuts are uneven.

Why is correcting the feed rate important?

The right feed rate ensures quality work and reduces wear and tear. Proper adjustments make the machine last longer and work better.Conclusion

The milling machine table feed rate controls how fast material moves under the cutting tool. It affects precision and surface finish. By learning to adjust the feed rate, you can improve your machining projects. Explore tutorials and guides to practice setting feed rates. This will help you master milling skills and create better projects.FAQs

What Factors Influence The Optimal Table Feed Rate In A Milling Machine Operation?The table feed rate in a milling operation depends on several things. First, consider the material you’re cutting, like wood or metal. Next, think about the size of your tool—big or small. Also, how fast you want the machine to go matters. All these factors help decide the best speed for your machine table.

How Do You Calculate The Appropriate Table Feed Rate For Different Types Of Milling Cutters?To find the right table feed rate, you start with the cutter’s speed. This is how fast the cutter spins. Next, you check the number of teeth on the cutter. Then, multiply the speed by the number of teeth, and finally, adjust based on the material being cut. This helps the machine cut smoothly without breaking anything.

What Are The Consequences Of Setting The Table Feed Rate Too High Or Too Low In A Milling Process?If you set the table feed rate too high in milling, the machine will move too fast. This can make the cutter break or wear out quickly. If you set it too low, the process will take a very long time. It can also make the cutter rub instead of cutting, which dulls it. So, finding the right speed is very important!

How Does Material Type Affect The Selection Of The Table Feed Rate In Milling?Different materials need different speeds when milling, which means cutting them. Soft materials like plastic cut quickly, so we use a fast feed rate. Hard materials like metal cut slowly, so we need a slow feed rate to avoid breaking the tool. Choosing the right speed keeps the milling safe and helps make a nice part.

What Tools Or Software Can Assist In Determining The Correct Table Feed Rate For Specific Milling Operations?To find the right feed rate for milling, you can use special computer programs. One tool is called a “calculator app” on your phone. It helps you do the math quickly. There are also special “machining software” programs made just for this. These tools tell you how fast the tool should move.