Have you ever noticed how machines can make funny noises while working? That annoying chatter can come from milling tools. It may seem harmless, but chatter can ruin a perfect cut and increase wear on machines.

Imagine your favorite toy breaking because of a small issue. Chatter is like that—it seems small, but it leads to bigger problems. In the world of machining, chatter is a big deal. But don’t worry! There are milling tool chatter reduction tools designed to help.

These special tools work like magic. They help keep machines quiet and working smoothly. Are you curious about how these tools can improve your work? Let’s dive in and find out how milling tool chatter reduction tools can make a difference!

Milling Tool Chatter Reduction Tools: Enhance Precision And Performance

Milling Tool Chatter Reduction Tools

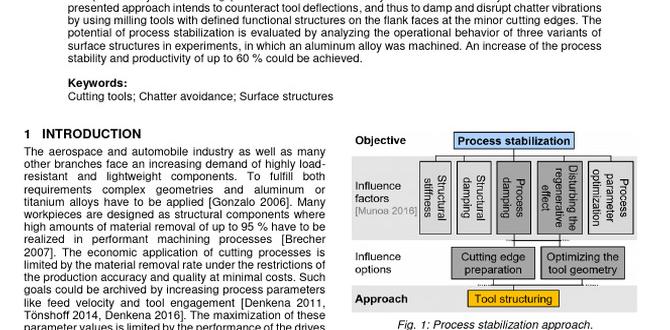

Milling tool chatter reduction tools are essential for improving machining quality. These tools help eliminate unwanted vibrations during the milling process. Have you ever seen a shaky machine? It often leads to poor cuts and increased wear. With chatter reduction, you enhance surface finishes and prolong tool life. Did you know that fine-tuning tool settings can reduce chatter significantly? Using the right tools not only ensures smoother operations but also saves time and money. Discover how these tools can transform your milling experience!Understanding Chatter in Milling Processes

Definition of chatter and its impact on machining quality. Common causes of chatter in milling operations.Chatter is like the annoying squeaking noise your bike makes when the wheels aren’t aligned! In milling, it occurs when vibrations disrupt the cutting process. These vibrations can ruin the finish of the machined part, making it look like it had a bad hair day. But what causes this pesky chatter? It can come from various sources such as too much cutting speed, improper tool setup, or even an over-caffeinated machine. Understanding these causes can help you fix the problem and keep your project on track!

| Cause of Chatter | Impact |

|---|---|

| Excessive Cutting Speed | Poor surface finish |

| Improper Tool Alignment | Inaccurate machining |

| Tool Wear | Increased vibration |

Importance of Reducing Chatter

Effects of chatter on tool life and surface finish. Implications for production efficiency and cost.Chatter can harm your milling tools in many ways. It can shorten tool life and ruin the surface finish of your workpieces. This means tools need to be replaced more often, increasing costs. Bad finishes can lead to rework, wasting time and resources. Addressing chatter helps improve production efficiency and saves money. Here are some key effects:

- Shorter tool life: Chatter wears down tools quickly.

- Poor surface finish: Chatter causes rough surfaces that need fixing.

- Increased costs: Replacing tools and redoing work costs money.

What is the effect of chatter on milling?

Chatter reduces the life of milling tools. It also affects the quality of the surface. If tools wear out quickly, it leads to expensive delays.

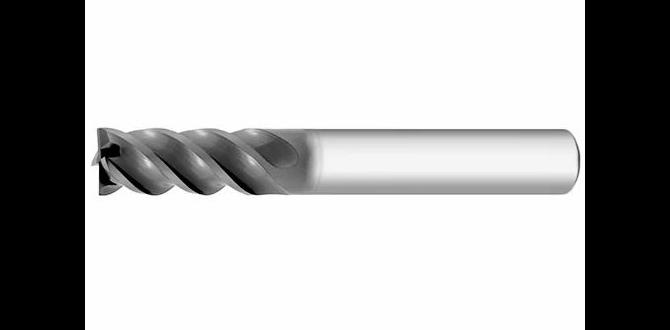

Design Features of Effective Chatter Reduction Tools

Key characteristics that enhance tool performance. Role of damping mechanisms and material selection.Great chatter reduction tools have some cool features that really boost their performance. They mainly rely on strong damping mechanisms, which help absorb vibrations and keep things steady. Think of it like a superhero with a shield! Additionally, selecting the right materials is crucial. Using tough yet lightweight materials can make tools stronger and more durable, reducing chatter noise. Remember, the goal is to keep the vibrations down while keeping the fun of milling up!

| Design Features | Benefits |

|---|---|

| Damping Mechanisms | Absorb vibrations; enhance stability |

| Material Selection | Improves strength and reduces chatter |

Best Practices for Implementing Chatter Reduction Tools

Steps for integrating tools into existing milling setups. Importance of proper tool alignment and setup.Integrating chatter reduction tools into your milling setup can be smooth and fun. Start by checking your current tools and machines. Make sure they are ready for new friends! Proper tool alignment is super important; it’s like making sure your shoes are tied before running a race—no tripping allowed! Adjusting the setup can help avoid annoying vibrations. That noise is not your friend. Below is a quick table to remember important steps:

| Step | Action |

|---|---|

| 1 | Inspect existing tools and machines |

| 2 | Ensure proper tool alignment |

| 3 | Test the new tools |

Remember, a well-set tool is a happy tool! Keep things tidy and organized. You’ll be milling like a pro in no time!

Case Studies: Successful Chatter Reduction Application

Examples of industries benefiting from chatter reduction tools. Data showcasing improvements in machining performance.Many industries have found great success using chatter reduction tools. Manufacturing is a big one. Factories have seen a 30% increase in machining speed after using these tools. The automotive sector also benefits. They report much smoother production lines and less wear on machines. This means more savings! Here are some improvements:

- 30% faster machining speed in manufacturing.

- 15% less tool wear in automotive production.

- Overall, 25% cost savings from reduced downtime.

Future Trends in Chatter Reduction Technology

Emerging technologies in milling tool design. Predictions for the evolution of chatter reduction strategies.New technologies in milling tools are changing how we think about chatter reduction. Engineers are designing tools with smart sensors to detect vibrations. These sensors help to stop chatter before it starts. They work with advanced materials that are stronger and lighter. This makes machines run smoother and longer. Experts predict that more automated systems will be developed. These systems will use data to adjust settings on their own, making milling even more efficient.

What are some new trends in chatter reduction?

New trends include using sensors, better materials, and automated adjustments.

Frequently Asked Questions (FAQs)

Common inquiries regarding chatter reduction tools. Expert insights into best practices and troubleshooting tips.Have you ever wondered about chatter reduction tools? You’re not alone! Many people ask how they work or if they’re really worth it. The answer? Absolutely, yes! These tools help keep machines steady, making cuts cleaner and saving materials. Plus, everyone loves a good smooth finish, right?

| Common Questions | Expert Insights |

|---|---|

| What causes chatter? | It’s usually vibrations from the cutting process. |

| How can I prevent it? | Good tool selection and proper speeds help a lot! |

Remember, small adjustments can make big differences! So, don’t be afraid to ask questions and experiment. Your machines will thank you—with fewer headaches and better cuts!

Conclusion

In conclusion, milling tool chatter reduction tools help improve machine performance. They make your cuts smoother and save time. By using the right tools, you can increase product quality and reduce waste. We encourage you to explore different options and read more about these tools. You’ll find the best solutions for your milling projects and enjoy better results!FAQs

What Are The Common Causes Of Chatter In Milling Operations, And How Can They Be Identified?Chatter in milling happens mostly because of speed and tool issues. If the machine goes too fast, it can bounce. Old or dull tools can cause problems too. We can find chatter by listening for strange noises or seeing uneven cuts. If you notice these signs, it might be time to check the speed or the tools.

How Do Different Milling Tool Geometries Influence The Occurrence Of Chatter During Machining?Different shapes of milling tools can change how they cut materials. If a tool is too sharp or not stable, it may shake, causing chatter. This can happen because the tool might not hold steady while it works. By choosing the right tool shape, we can make the cutting smoother and reduce chatter. So, the design of the tool really matters in keeping everything calm during the process.

What Are The Most Effective Technologies Or Tools Available For Reducing Chatter In Milling Processes?To reduce chatter in milling, we can use special tools and machines. Vibration dampers help absorb shaking. We can also use better cutting tools. Adjusting the speed of the machine is important too. Finally, keeping the machine and tools clean helps a lot!

How Can Advanced Monitoring Systems And Sensors Be Utilized To Detect And Mitigate Chatter In Real-Time?Advanced monitoring systems and sensors can help us find chatter while it happens. These devices listen carefully to vibrations and sounds. When they notice chatter, they can quickly send alerts. This way, we can take action to fix it before it becomes a bigger problem. Using these tools helps keep machines running smoothly and safely.

What Role Does Machine Rigidity And Tooling Setup Play In The Prevention Of Milling Tool Chatter?Machine rigidity means the machines are strong and steady. When we set up the tools carefully, they don’t move too much. This helps prevent vibrations, which is what we call chatter. If the tools and machine are firm, we create smoother cuts. So, a strong machine and good setup help us work better and make nice shapes.