Have you ever wondered which milling tools fit best with your machinery? Choosing the right tool can feel like a puzzle. With so many options available, it’s easy to get lost. But don’t worry; a milling tool compatibility chart can help you!

Imagine you’re ready to start a big project. You gather your equipment, but then you find out that some of your tools don’t match. Frustrating, right? A compatibility chart takes the guesswork out of the equation.

Here’s a fun fact: Did you know that using the wrong milling tool can damage not just the tool but also your machine? It’s true! Making sure your tools are compatible can save you time and money.

This article will explore how to read a milling tool compatibility chart. You’ll learn why it’s essential for your projects. By the end, you’ll feel confident in making the right choices for your milling needs.

Milling Tool Compatibility Chart: Your Essential Guide

Milling Tool Compatibility Chart: Key Insights

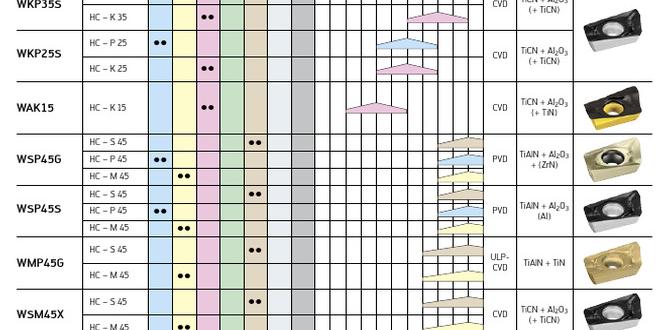

Discover how a milling tool compatibility chart helps you choose the right tools for your projects. This chart shows which milling cutters fit specific machines. Using the wrong tool can lead to poor results or damage. For instance, if you use a cutter that’s too big, it might not fit at all! Curious about making your work easier and more efficient? Understanding compatibility can save you time and money. Make sure you check this chart before starting your next project!Milling Tool Compatibility Basics

Explanation of compatibility terms used in milling tools. Common factors affecting tool compatibility (size, material, design).Compatibility is key in milling tools. It refers to how well tools work together. Size matters, as a tool that’s too big or too small won’t fit correctly. The material used also affects performance; for example, some materials are tougher than others. Design plays a role too—some shapes just don’t cooperate well. Always check the milling tool compatibility chart to avoid a frustrating day at the shop!

| Factor | Description |

|---|---|

| Size | The tool must fit the machine! |

| Material | Different materials handle tasks differently. |

| Design | Shapes can affect how tools work together. |

Industry Standards for Milling Tool Compatibility

Discussion on ANSI, ISO, and other relevant standards. Significance of adhering to industry standards for optimal performance.Standards like ANSI and ISO help make sure tools work well together. These guidelines explain how tools should be made. This is important for safety and performance. When everyone follows them, tasks become easier and safer.

- ANSI (American National Standards Institute) creates standards for tool safety.

- ISO (International Organization for Standardization) ensures global quality of tools.

Using these standards means less chance of mistakes. It leads to better results and saves time.

Why are industry standards important?

Following industry standards helps businesses work better. It means tools fitted with the right milling tool compatibility chart will run smoothly together and achieve goals faster.

Key Benefits:

- Increased safety

- Better tool lifespan

- Improved efficiency

Creating a Milling Tool Compatibility Chart

Key factors to include in a compatibility chart. Stepbystep guide on how to develop your own chart.Creating a milling tool compatibility chart is easy and helpful. You want to include key factors like tool types, materials, and sizes. Here’s a simple step-by-step guide to make your own chart:

- Identify different milling tools you have.

- List materials each tool can work with.

- Include tool sizes and specifications.

- Note any special features or uses.

- Keep it organized for easy reference.

By following these steps, you can create a useful chart. This chart will save you time and ensure you use the right tool.

What are the key factors for your chart?

Key factors include tool type, compatibility with different materials, and dimensions.

Using the Compatibility Chart Effectively

Tips on interpreting the chart for different milling projects. Case studies of successful projects utilizing the chart.Understanding the milling tool compatibility chart helps make good choices for projects. Here are some tips:

- Check tool types: Know the tools listed for your project.

- Match materials: Link the tool to the materials you use.

- Size matters: Be aware of sizes that fit your milling machine.

Success stories show how useful this chart is. One project used the chart to pick the right tool, resulting in a perfect finish. Another team improved efficiency by 20%. Using the chart can really help!

Why is a compatibility chart important?

A compatibility chart helps you select the right tools, ensuring safety and quality in milling projects.

Future Trends in Milling Tool Compatibility

Innovations shaping the future of milling tools and compatibility. Predictions for advances in compatibility technology and tools.New ideas are changing milling tools. These innovations help tools work better together. Smart technology is becoming common. It helps in choosing the right tools without guessing.

Predictions for the future include:- More automated compatibility checks.

- Advanced material usage for longer lasting tools.

- Better data sharing for quick access to information.

These trends make it easier for users to find what they need. Imagine picking the right tool with a click! It makes work faster and safer.

How will technology impact milling tool compatibility?

Technology will lead to smarter tools that connect better, making work easier and more efficient.

Conclusion

In summary, a milling tool compatibility chart helps you choose the right tools easily. It shows which tools fit with different machines and materials. By using this chart, you can improve your projects and save time. We encourage you to explore these charts for your next milling task and learn more about their features for even better results!FAQs

What Factors Should Be Considered When Selecting Milling Tools Based On Compatibility With Specific Machines Or Materials?When choosing milling tools, you should think about the machine you have. Make sure the tool fits into your machine properly. Also, consider the material you will be cutting. Different materials need different types of tools. Lastly, check how hard the tool is and how long it will last.

How Does The Diameter Of A Milling Cutter Affect Its Compatibility With Different Milling Machines?The diameter of a milling cutter is important because it needs to fit the milling machine. If the cutter is too big, it won’t fit or could harm the machine. A smaller cutter can work with different machines easily. So, we must choose the right size for each machine to work safely.

Are There Standardized Charts Available For Determining The Compatibility Of Various Milling Tools With Cnc Machines?Yes, there are charts that help us find which milling tools work with CNC machines. These charts are like guides you can use. They show you which tools fit best and how to use them safely. You can often find these charts online or in tool manuals. Just remember to check the chart before you start working!

What Are The Common Types Of Milling Tools, And How Can You Determine Their Compatibility With Various Workpiece Materials?Common types of milling tools include end mills, face mills, and ball nose mills. You can tell if a tool works with a material by checking its hardness. Softer materials like wood need different tools than harder metals like steel. Always read the tool’s instructions to make sure it’s right for what you’re working on.

How Can Toolholders Impact The Compatibility Of Milling Tools In Different Machining Setups?Toolholders are like special cases for milling tools. They hold the tools tightly and connect them to the machine. If the toolholder doesn’t fit well, the tool won’t work right. This can cause problems, like bad cuts or broken tools. So, choosing the right toolholder is very important for doing a good job.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting Milling Tools Based On Compatibility With Specific Machines Or Materials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing milling tools, you should think about the machine you have. Make sure the tool fits into your machine properly. Also, consider the material you will be cutting. Different materials need different types of tools. Lastly, check how hard the tool is and how long it will last.”}},{“@type”: “Question”,”name”: “How Does The Diameter Of A Milling Cutter Affect Its Compatibility With Different Milling Machines? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The diameter of a milling cutter is important because it needs to fit the milling machine. If the cutter is too big, it won’t fit or could harm the machine. A smaller cutter can work with different machines easily. So, we must choose the right size for each machine to work safely.”}},{“@type”: “Question”,”name”: “Are There Standardized Charts Available For Determining The Compatibility Of Various Milling Tools With Cnc Machines? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are charts that help us find which milling tools work with CNC machines. These charts are like guides you can use. They show you which tools fit best and how to use them safely. You can often find these charts online or in tool manuals. Just remember to check the chart before you start working!”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Milling Tools, And How Can You Determine Their Compatibility With Various Workpiece Materials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of milling tools include end mills, face mills, and ball nose mills. You can tell if a tool works with a material by checking its hardness. Softer materials like wood need different tools than harder metals like steel. Always read the tool’s instructions to make sure it’s right for what you’re working on.”}},{“@type”: “Question”,”name”: “How Can Toolholders Impact The Compatibility Of Milling Tools In Different Machining Setups? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Toolholders are like special cases for milling tools. They hold the tools tightly and connect them to the machine. If the toolholder doesn’t fit well, the tool won’t work right. This can cause problems, like bad cuts or broken tools. So, choosing the right toolholder is very important for doing a good job.”}}]}