Have you ever wondered how to keep your milling tools sharp and effective? The cutting edge of a milling tool is like a superhero’s cape; it makes all the difference. When it’s prepared well, it performs wonders. When it’s dull, it struggles to do its job.

Using proper cutting edge prep techniques can transform your work. Imagine starting a project with a perfectly sharp tool, ready to slice through materials smoothly. You won’t just save time; you’ll also create better results.

Did you know that even small changes in how you prepare the cutting edge can lead to big improvements? Many people overlook this aspect of milling. However, investing a little time in prep can yield fantastic rewards. So, let’s dive into the fascinating world of milling tool cutting edge prep techniques.

Milling Tool Cutting Edge Prep Techniques For Precision Machining

Milling Tool Cutting Edge Prep Techniques

Preparing the cutting edge of a milling tool can greatly impact its performance. Key prep techniques include sharpening, coating, and cleaning. Did you know that a clean cutting edge lasts longer and cuts smoother? Regularly checking tool conditions also helps avoid damage. Are you struggling with uneven cuts? Proper edge prep can fix that. By investing a little time in these techniques, you can enhance your milling projects and achieve better results!Understanding Milling Tool Geometry

Explanation of different milling tool shapes and designs. Importance of tool geometry in cutting performance.Milling tools come in various shapes, each with a job to do. There’s the flat end mill for making smooth surfaces and the ball end mill for rounded edges. Each design has its own geometry, which is super important for cutting performance. Good tool shape helps cut faster and last longer. Remember, a happy tool is a sharp tool! So, always keep it well-prepped. After all, nobody likes a dull day – not even your tools!

| Tool Shape | Purpose |

|---|---|

| Flat End Mill | Smooth surfaces |

| Ball End Mill | Rounded edges |

| Corner Radius Mill | Reduce tool wear |

| Roughing Mill | Fast material removal |

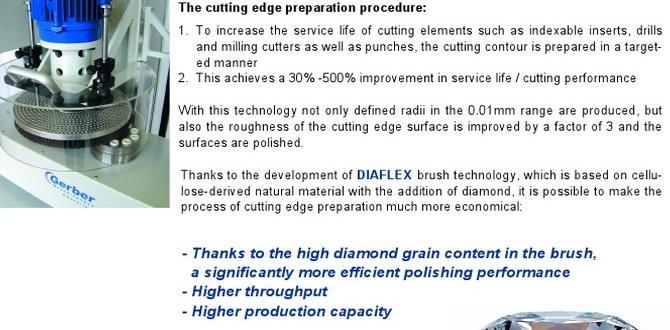

Cutting Edge Preparation Methods

Techniques for sharpening and honing edges. Use of advanced machinery in edge preparation.Sharpening and honing edges is like giving your tools a fresh haircut! First, you can use sharpening stones or diamond plates to create a fine edge. This simple act makes your tools cut like a hot knife through butter. Plus, advanced machines, like CNC grinders, help in edge preparation with precision. They take out the guesswork and leave you with sharp, beautiful edges. So, whether you’re a DIY enthusiast or a pro, remember: a sharp tool is your best friend!

| Technique | Benefit |

|---|---|

| Sharpening Stones | Creates a fine edge |

| Diamond Plates | Lasts longer and works faster |

| CNC Grinders | Precise and consistent edges |

Effects of Cutting Edge Condition on Performance

Discussion on wear and tear of cutting edges. Impact of edge preparation on tool life and workpiece quality.The condition of a cutting edge can truly make or break a milling tool’s performance. Worn edges can lead to poor cuts and increased wear on the tool. This means your tool could retire early, much like a runner who didn’t stretch. Good edge preparation can help the tool last longer and create better workpieces. According to studies, a sharpened edge can improve cutting life by up to 30%. Who doesn’t want their tools to be superheroes instead of sidekicks?

| Edge Condition | Tool Life | Workpiece Quality |

|---|---|---|

| Sharp | Up to 30% Longer | Higher Precision |

| Worn | Shortened | Lower Quality |

Measuring and Inspecting Cutting Edges

Tools and techniques for precise edge measurement. Importance of regular inspections for maintaining tool effectiveness.To keep tools sharp and ready, measuring cutting edges is essential. A right tool can save time and money. Using tools like micrometers and calipers lets you gauge tiny details with precision. Regular inspections are like health check-ups; they prevent surprises and keep your tools effective. Every professional knows a dull edge is a sad edge, so don’t let that happen!

| Tool | Purpose |

|---|---|

| Micrometer | Measures small distances accurately. |

| Caliper | Checks width and depth of edges. |

| Magnifying Glass | Inspects the edge for wear. |

Regular checks allow for adjustments, helping to keep cutting edges effective. Remember, a happy tool makes happy projects!

Best Practices for Cutting Edge Maintenance

Routine maintenance strategies to prolong tool life. Importance of correct storage and handling techniques.To keep your cutting tools sharp and long-lasting, follow these simple maintenance tips. First, check your tools regularly for any signs of wear. Store them in a dry place to prevent rust. Handle them carefully to avoid damaging the edges. Here are some easy points to remember:

- Clean tools after use.

- Keep tools in protective cases.

- Use proper techniques during handling.

By using these best practices, you can help your milling tools stay effective longer!

What are the best ways to store cutting tools?

Store cutting tools in a cool, dry place and use protective cases to prevent damage.

Case Studies: Successful Edge Preparation Techniques

Examples from various industries showcasing effective methods. Analysis of outcomes and improvements in production efficiency.Many businesses have found great success with edge preparation techniques. For example, a car manufacturing company improved their production speed by 20% using precise milling tools. In the aerospace industry, one firm reported a 15% reduction in waste after upgrading their cutting edges. These methods led to faster production times, less material wasted, and overall better quality.

- Car manufacturing: 20% increase in speed

- Aerospace: 15% waste reduction

These case studies show that putting effort into edge preparation really pays off.

What are effective edge preparation techniques?

Effective edge preparation techniques include sharpening a tool, maintaining a consistent angle, and choosing the right materials. These methods help create smoother cuts and longer-lasting tools.

Future Trends in Milling Tool Technology

Innovations in cutting edge materials and designs. Predictions on emerging techniques in tool preparation.New materials and designs are changing milling tools for the better. High-speed steel and ceramics are becoming popular. These materials last longer and cut better. Experts think more unique shapes will appear. These shapes will help tools work faster and smoother. Innovations make tool preparation easier. Here are some trends to watch:

- Smart technology in tools.

- New coatings for better performance.

- 3D printing for custom designs.

- Eco-friendly materials.

As tools improve, we can expect faster production and stronger products. It’s an exciting time for milling tools!

What are the future trends in milling tools?

Future trends include improved materials, smarter designs, and 3D printing. These changes help tools last longer and work more efficiently.

Conclusion

In summary, preparing the cutting edge of milling tools is essential for success. Proper techniques improve tool life and performance. You can enhance your skills by practicing edge preparation methods. Remember to keep your tools sharp and check them regularly. For more tips, explore reliable sources and tutorials. Let’s keep learning and working towards better results together!FAQs

What Are The Most Common Techniques Used For Prepping The Cutting Edges Of Milling Tools Before Use?Before using milling tools, we often sharpen the cutting edges. One common method is grinding, where we use a machine to smooth the edges. Another technique is honing, which makes the edges very sharp. We also clean the tools to remove dirt and grease. This helps them work better when cutting materials.

How Does Proper Cutting Edge Preparation Impact The Performance And Longevity Of Milling Tools?When you prepare the cutting edge of milling tools well, they work better. A sharp edge cuts faster and smoother. This means the tool can last longer without breaking. If we take care of the edge, it stays strong and helps us make better shapes and sizes in materials. So, good preparation is important for both performance and how long the tools last.

What Materials Are Typically Used For Sharpening And Preparing Milling Tool Cutting Edges?To sharpen and prepare milling tool cutting edges, we usually use special stones or grinding wheels. These materials help make the tools sharp and ready to cut. You can also find diamond tools, which are very strong and last a long time. Lastly, some people use files to smooth out the edges.

How Does The Geometry Of The Cutting Edge Influence The Choice Of Preparation Technique?The shape of the cutting edge affects how we prepare materials. If the edge is sharp and pointed, it cuts easily and can make clean lines. For flat edges, we might use techniques that push or scrape instead. Choosing the right technique helps us get the best results for our project.

What Are The Differences Between Manual And Automated Cutting Edge Prep Techniques In Milling Operations?Manual cutting edge prep means you do everything by hand. You use tools like files and sandpaper to shape the metal. Automated cutting edge prep uses machines to do the work for you. These machines are faster and can make more precise shapes without much effort from you. So, manual is hands-on, while automated uses technology to help.