Have you ever wondered how machines make perfect cuts? It’s like magic, right? But in the world of manufacturing, everything comes down to precision. One of the secrets to accuracy is something called a milling tool deflection simulation tool.

This special tool helps engineers see how a milling tool bends or flexes during its work. Even small changes can cause big problems in machining. Imagine trying to eat soup with a fork—frustrating, right? That’s how it feels when tools don’t perform as expected!

Using a milling tool deflection simulation tool can save time and money. It allows engineers to test and improve designs before they start making products. What if we told you that this tool can help create safer, stronger, and more reliable parts? That’s pretty cool!

So, the next time you see a perfectly cut piece of metal or wood, remember the hidden magic of deflection simulation. It’s not just about cutting; it’s about cutting smart!

Milling Tool Deflection Simulation Tool: An Essential Guide

Milling Tool Deflection Simulation Tool

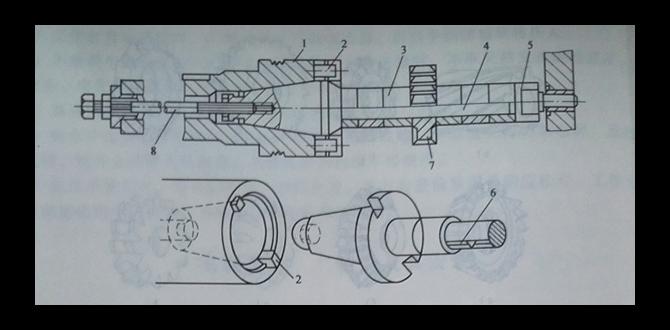

Milling tool deflection simulation tools help designers predict how tools bend during cutting. This technology is vital for creating precise, high-quality parts. Imagine if a tool shifts just slightly; it can ruin the entire piece! Understanding tool deflection improves machining accuracy and reduces waste. Readers learn how these simulations save time and money in manufacturing. It’s fascinating to think about how computers can help in crafting perfect components, isn’t it?Understanding Milling Tool Deflection

Definition of milling tool deflection. Importance of deflection in machining processes.Milling tool deflection happens when a cutting tool bends or moves during machining. Think of it like a bending straw — it can change your drink’s direction! This deflection can affect how accurately a part is made, and that’s why understanding it is crucial. If a tool bends too much, it can lead to uneven cuts or even ruined parts. Remember, a happy tool is a straight tool! Here’s a quick look at why it matters:

| Importance of Tool Deflection |

|---|

| Improves accuracy in machining. |

| Helps avoid tool wear and damage. |

| Ensures better surface finish on parts. |

Factors Affecting Milling Tool Deflection

Material properties of the tool and workpiece. Cutting parameters: speed, feed rate, and depth of cut.Several important factors influence how milling tools deflect. The first is the material properties of both the tool and the workpiece. Harder materials lead to less deflection. The next factors are cutting parameters, such as speed, feed rate, and depth of cut. Higher speeds or deeper cuts can increase deflection. Understanding these factors helps in achieving better results. Here’s a quick breakdown:

- Material Properties: Hardness, toughness, and brittleness play key roles.

- Cutting Speed: Faster speeds can lead to more deflection.

- Feed Rate: Higher rates may increase tool load and flex.

- Depth of Cut: Deeper cuts cause more stress and deflection.

What materials affect milling tool deflection?

Harder materials reduce deflection, while softer materials increase it. Choosing the right materials is crucial for better performance.

Types of Milling Tool Deflection Simulation Tools

Software options: commercial vs. opensource. Key features to look for in simulation tools.Different types of milling tool deflection simulation tools exist, each with unique features. You can choose from commercial software, which often offers robust support, or open-source options that are free to use. Look for these key features:

- User-friendly interface

- Accurate deflection calculations

- Integration with existing CAD systems

- Customization options

Both types can help you design better tools and improve your work.

What should I consider when choosing simulation tools?

Key factors include cost, ease of use, and accuracy. These choices can affect your project results!

How to Choose the Right Simulation Tool

Criteria for selecting a simulation tool based on project needs. Comparison of popular milling tool deflection simulation tools.Picking the right simulation tool can feel like choosing the right ice cream flavor—so many options, but a bad choice can ruin your day! Start by understanding your project needs: consider aspects like accuracy, ease of use, and compatibility with your current software. Popular tools include ANSYS, SolidWorks, and COMSOL, each with its strengths. Here’s a quick comparison to help you select the best one:

| Tool | Accuracy | Ease of Use | Cost |

|---|---|---|---|

| ANSYS | High | Moderate | Expensive |

| SolidWorks | Good | Easy | Moderate |

| COMSOL | Very High | Complex | High |

Remember, a simulation tool is like a trusty toolbox; the right one can make all the difference in your project’s success!

Implementing Simulation in the Milling Process

Steps to perform effective deflection simulations. Case studies demonstrating successful implementation.Starting a deflection simulation is like warming up before a big game. First, you gather data about your milling tool and the material you’re using. Next, you use software designed for simulations. This will help you see how your tool reacts under different conditions. It’s like watching your favorite superhero in action, but with less spandex!

Several companies have successfully implemented these simulations. For example, one factory reduced tool wear by 30% using this approach. Now that’s impressive! Here’s a quick look at some steps involved in effective simulations:

| Step | Description |

|---|---|

| Data Collection | Gather all necessary info on tools and materials. |

| Simulation Software | Choose a reliable milling simulation tool. |

| Testing Conditions | Set up various scenarios to run the simulation. |

| Analyze Results | Look at how deflection affects performance. |

With these steps, you can navigate the world of milling simulations like a pro! Remember, staying ahead in manufacturing means being smart, not just strong.

Limitations of Current Deflection Simulation Tools

Common challenges faced during simulations. Areas for improvement in existing tools.Deflection simulation tools help us understand how milling tools behave. However, they have some challenges. Many users report that these tools are not always accurate. They might not consider all factors, like temperature and vibration. Also, the user interface can be confusing.

- The simulations can take too long.

- Some tools do not show real-world conditions.

Improvements are needed. Better user guides would help everyone use the tools more effectively. Adding more features could make them more reliable. As technology improves, we expect these tools to get better.

What challenges do users face with deflection simulation tools?

Users often face issues with accuracy, confusing interfaces, and long processing times.Future Trends in Milling Tool Deflection Simulation

Emerging technologies in simulation tools. Predictions for the evolution of milling techniques and tool performance.New tech is changing how we look at milling tools. The latest simulation tools can predict how tools will behave. These tools help engineers design better machines. This means less waste and more efficiency. Future milling techniques may focus on smart materials that adjust to different tasks. We might also see virtual reality used for training and testing. This could make learning easier and more fun.

What Are The Future Trends?

Emerging technologies will likely lead to tools that predict problems before they happen. This can save time and money. Here are some trends to watch:

- Use of AI for better predictions.

- More realistic simulations with virtual reality.

- Improved materials that last longer.

- Greater focus on energy efficiency.

Best Practices for Reducing Tool Deflection

Techniques to minimize deflection during milling. Design considerations for enhanced tool stability.Tool deflection can be a pesky problem in milling. To keep your milling tools on track, try using shorter tool lengths. This can help minimize wobbles. Choosing the right material for your tools is also key; harder materials tend to hold their shape better. Don’t forget the importance of a proper setup! A solid fixture can make your tools feel like they’re on vacation—always stable. Lastly, always check your tool paths. A well-planned path reduces surprises—and deflection!

| Technique | Description |

|---|---|

| Short Tool Lengths | Reduces flex during cuts. |

| Strong Materials | Harder materials resist bending. |

| Steady Setup | Secure fixtures keep tools stable. |

| Planned Tool Paths | Avoid surprises that cause deflection. |

Conclusion

In conclusion, milling tool deflection simulation tools help you understand how tools behave during use. They improve accuracy in machining and reduce mistakes. By using these tools, you can create better products and save time. We encourage you to explore more about this topic and see how simulation tools can enhance your work in milling.FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Tool Deflection Simulation Tools:Milling tool deflection simulation tools help us see how tools bend or move when they cut materials. This helps us learn what to change for better cutting. We use special computer programs to do this. With these tools, we can make our machines work more accurately. It’s like checking if a toy car moves straight or wobbles before playing with it!

Sure! Please tell me the question you want me to answer.

What Are The Key Factors That Influence Tool Deflection During The Milling Process, And How Can Simulation Tools Help In Analyzing These Factors?Tool deflection happens when the cutting tool bends during milling. Key factors include how hard the material is, how fast we work, and how much pressure we use. If the tool is weak or worn, it can bend more easily. Simulation tools can help us see how these factors affect the tool before we actually use it. This way, we can find the best ways to prevent problems.

How Does The Choice Of Milling Tool Geometry Impact The Accuracy Of Deflection Predictions In Simulation Scenarios?The shape of the milling tool, like its angle and edges, affects how it cuts material. If the tool is shaped well, it helps us predict how much it will bend or move while working. This makes our simulations more accurate. If we choose the wrong shape, the predictions can be off, leading to mistakes. So, a good tool shape helps us understand and plan better.

In What Ways Can Milling Tool Deflection Simulation Tools Be Integrated Into Cad/Cam Systems To Enhance Machining Efficiency?We can add milling tool deflection simulation tools to CAD/CAM systems to help us design better. These tools show how our cutting tools will bend while working. This helps us pick better tools and avoid problems. By doing this, we can make our machines work faster and save energy too. Overall, it makes sure our projects turn out nice and smooth.

What Are The Benefits Of Using Finite Element Analysis (Fea) In Milling Tool Deflection Simulations Compared To Traditional Analytical Methods?Using finite element analysis (FEA) helps us see how tools bend and move while they work. Unlike old methods, FEA gives us a clear picture of what happens when we cut materials. It shows problems more accurately, so we can fix them before starting. This saves time and money in making better tools. Overall, FEA helps us make stronger and more precise milling tools.

How Can Manufacturers Use Simulation Tools To Optimize Cutting Parameters And Reduce Tool Wear Related To Deflection In Milling Operations?Manufacturers can use simulation tools to find the best cutting settings for their machines. These tools help us see how different speeds and pressures change the cutting process. By adjusting these settings, we can reduce tool wear, which is when tools get damaged over time. Less tool wear means we can make better parts and save money. Overall, using simulations makes our work easier and more efficient!