Have you ever looked at a complicated shape and wondered how to recreate it? Designing an object with odd curves and angles can be tricky. This is where the right milling tool for irregular contours comes in handy.

Imagine a sculptor shaping a beautiful statue. They need the right tools to bring their vision to life. Just like that sculptor, engineers and designers rely on specialized milling tools. These tools can carve out unusual shapes. They help turn creative ideas into real, tangible objects.

Did you know that some milling tools can reach the most intricate details in just a few minutes? With the proper tool, complex designs become easier. This not only saves time but also adds a professional touch to every project.

Join us as we explore the exciting world of milling tools for irregular contours. You’ll discover how these tools work, their benefits, and how they can transform your ideas into reality.

Effective Milling Tool For Irregular Contours: A Guide

Milling Tool for Irregular Contours

Milling tools for irregular contours are essential for precise shaping in various projects. These tools can easily navigate complex shapes, helping creators achieve stunning designs. Have you ever tried to carve a unique piece but struggled with tricky edges? This is where a milling tool shines. Fun fact: these tools often use different cutting bits to handle diverse materials! This flexibility allows users to explore endless possibilities in their crafts. Discover how these handy tools can transform your work!Understanding Irregular Contours in Machining

Definition and significance of irregular contours in manufacturing. Common industries and applications that require milling tools for irregular shapes.Irregular contours are shapes that don’t fit a standard design. They come in all sorts of wild forms, sort of like a funky potato! These shapes matter in manufacturing because they help create unique products that stand out. Many industries, like automotive and aerospace, need milling tools to shape these interesting contours. Think of how an artist uses brushes to create a masterpiece. In the same way, milling tools help craft special designs.

| Industry | Application |

|---|---|

| Automotive | Custom engine parts |

| Aerospace | Aircraft components |

| Medical | Specialized surgical tools |

Choosing the Right Milling Tool for Specific Applications

Factors to consider when selecting a milling tool (material, shape, size). Case studies or examples of successful milling projects using specific tools.Picking the perfect milling tool is like choosing ice cream toppings. It depends on what you’re making! First, think about material. Steel works for hard jobs, while carbide shines for intricate shapes. Next is shape; some tools are star-shaped for fancy details. Don’t forget the size; a tool that’s too big might cause a meltdown, like an ice cream cone on a hot day!

For example, a project using a special corner radius tool helped a team create smooth curves in metal parts. They finished the job faster and with fewer mistakes. So, when selecting your tool, remember: right tool, happy project!

| Factor | Considerations |

|---|---|

| Material | Choose based on job difficulty |

| Shape | Pick the one for your design |

| Size | No big tools for small tasks! |

Techniques for Milling Irregular Contours Effectively

Recommended machining strategies (e.g., adaptive machining, 5axis milling). Tips for setting up the milling machine for optimal performance.Milling irregular shapes can be tricky. To do it well, use smart strategies. Adaptive machining adjusts to changes in shape while cutting. This makes it easier to shape complex designs. 5-axis milling offers even more flexibility. It allows movements in different directions, giving better accuracy. Here are some tips for setting up your milling machine:

- Keep the workpiece steady.

- Check tools for sharpness.

- Adjust feed rates based on material type.

With these methods, you’ll create smooth and perfect contours!

What is adaptive machining?

Adaptive machining is a method that changes cutting paths to meet the shape of the material. This helps avoid mistakes and ensures better results.

Challenges and Solutions in Milling Irregular Contours

Common challenges faced by machinists when working with irregular contours. Solutions and best practices to overcome these challenges.Machinists face many challenges while milling irregular contours. These challenges include difficulty in achieving smooth surfaces and maintaining precise dimensions. The tools can also wear out quickly. To tackle these issues, machinists can use the following best practices:

- Use the right milling tool type for irregular shapes.

- Keep tools sharp to avoid damage.

- Regularly inspect and maintain equipment.

- Adjust feeds and speeds based on material.

- Utilize software for better design simulation.

By employing these solutions, machinists can improve their results while working with complex designs.

What are common problems in milling irregular contours?

Common problems include uneven surfaces, incorrect dimensions, and fast tool wear.Maintenance and Care for Milling Tools

Importance of regular maintenance to prolong the life of milling tools. Best practices for cleaning, storage, and inspection of milling tools.Taking care of milling tools is very important. Regular maintenance helps tools last longer and work better. Cleaning tools removes dirt and dust. Store them in a dry place away from moisture. Check them often for any signs of damage. Here are some easy tips:

- Clean after each use.

- Store in a protective case.

- Inspect for wear regularly.

Following these tips will keep your milling tools in great shape!

Why is regular maintenance important for milling tools?

Regular maintenance extends the life of milling tools and ensures better performance. Keeping them clean and checking for damages can save you money in the long run.

Future Trends in Milling Technology for Irregular Contours

Emerging technologies and innovations in milling tools and techniques. Predictions for how these advancements will change the landscape of machining irregular contours.Milling technology is changing fast. New tools and clever techniques are improving how we shape irregular contours. These advancements boost accuracy and speed in machining. Future tools will likely use smart features and advanced materials. Here are some exciting trends:

- Smart milling tools that adjust automatically.

- Advanced materials that last longer and cut better.

- 3D printing methods for unique shapes.

As these tools develop, machining will become easier and more precise. This will help industries make better products quickly.

What are the benefits of new milling technologies?

New milling technologies offer faster production, improved precision, and lower costs. These improvements make it simpler to create complex shapes.

Conclusion

In summary, milling tools for irregular contours help create unique shapes with precision. They are essential in various industries, from crafting to manufacturing. By using these tools effectively, you can improve your projects and get creative. Explore different types available and learn more about how to use them. It’s time to start shaping your ideas into reality!FAQs

What Are The Common Types Of Milling Tools Specifically Designed For Machining Irregular Contours?There are a few common milling tools for making shapes that aren’t straight. One tool is the ball end mill, which has a round tip that helps carve curves. Another tool is the corner radius end mill, which has rounded edges for smooth corners. You can also use a tapered end mill, which is great for creating angled surfaces. These tools help you shape materials in special ways!

How Do The Geometries And Materials Of Milling Tools Influence Their Performance When Working On Complex Shapes?The shapes and materials of milling tools are very important for their job. When a tool has the right shape, it can cut through tricky curves and angles better. Strong materials help the tool last longer, so it can keep working well on these complex shapes. If we use the wrong tool, it might break or make a messy cut. So, choosing the right tool helps us do a better job!

What Are The Advantages And Disadvantages Of Using Cnc Milling Machines For Producing Irregular Contours Compared To Traditional Milling Methods?CNC milling machines have some cool advantages. They can make very detailed shapes quickly and easily. You can also make changes in the design without needing new tools. This saves time and money. However, they can be expensive to buy and use. Plus, if something breaks, fixing it can be hard. Traditional milling can be slower but might cost less. So, each method has its good and bad sides.

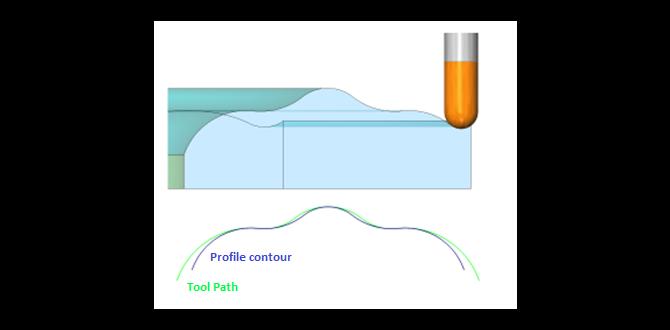

How Can Tool Path Optimization Improve The Efficiency And Accuracy Of Milling Operations On Irregularly Shaped Workpieces?Tool path optimization helps us plan the best route for the cutting tool. This means the tool moves in smoother paths, which saves time. It also reduces mistakes, making our work more precise. When we cut irregular shapes, good paths help us avoid wasted movements. So, we finish faster and with better results!

What Role Does The Choice Of Cutting Fluid Play In The Milling Process When Machining Irregular Contours, Particularly In Terms Of Tool Life And Surface Finish?Choosing the right cutting fluid is really important when you are milling or shaping materials. It helps keep the tools cool, so they last longer, which we call tool life. Good cutting fluid also helps make the surface smooth, which is called surface finish. So, using the right fluid means your tools work better and the finished product looks nicer.