Have you ever wondered how machines cut and shape materials? Milling tools play a crucial role in this process. They help create everything from car parts to small gadgets. But did you know the way these tools vibrate can affect their performance?

That’s where milling tool modal analysis techniques come in. They help engineers understand how tools behave when they are in action. By studying these vibrations, we can improve machining processes. Imagine having a tool that works perfectly every time!

In this article, we will explore how these analysis techniques work and why they matter. You’ll discover fun facts and insights that could change how you see everyday tools. Are you ready to dive into the fascinating world of milling tools and their hidden secrets?

Milling Tool Modal Analysis Techniques Explained Clearly

Milling Tool Modal Analysis Techniques

Milling tool modal analysis techniques help engineers understand how tools vibrate. Why is this important? Tools that vibrate too much can cause poor cuts and damage. By using these analysis methods, engineers can create better, more effective milling tools. They can test different shapes and materials to find the best designs. This not only saves time but also money in manufacturing. Imagine a world where tools last longer and work better—these techniques make that possible!Understanding Modal Analysis

Definition and purpose of modal analysis. Importance in milling tools and machinery.Modal analysis helps us understand how things vibrate. It studies the natural frequencies and modes of machines. For milling tools, it finds weak points to improve design and avoid failures. This makes machines safer and more efficient. The results guide engineers in creating better milling tools. Notably, a reliable tool can cut costs and save time.

What is modal analysis and why is it important?

Modal analysis is a method used to study the vibration patterns of machines. It is crucial because it helps engineers design stronger and more reliable milling tools.Key reasons for using modal analysis:

- Improves tool performance

- Increases safety

- Reduces maintenance costs

Types of Modal Analysis Techniques

Experimental Modal Analysis (EMA). Analytical Modal Analysis (AMA). Numerical Modal Analysis (NMA).There are three main types of modal analysis techniques. First, we have Experimental Modal Analysis (EMA). This method involves testing real-life samples. Think of it as throwing a party and measuring how the guests dance! Next is Analytical Modal Analysis (AMA). This technique uses math and formulas to predict how things behave, kind of like a fortune teller but with equations. Finally, we have Numerical Modal Analysis (NMA). This method involves computer simulations. It’s like having a virtual puppet show to see how things move without making a mess!

| Technique | Description |

|---|---|

| EMA | Testing real-life samples to determine how they vibrate. |

| AMA | Using mathematical models to predict behavior. |

| NMA | Using computer simulations to analyze movements. |

Applications of Modal Analysis in Milling

Vibration control in milling operations. Enhancing tool life and performance. Reducing wear and tear on machinery.In milling, modal analysis helps keep things steady. By controlling vibrations, it allows tools to cut smoothly. This boosts tool life and performance, making cutting faster and more efficient. Less wear means our machines don’t get tired as quickly—sort of like how we feel after a long day at school. Think of it as giving your tools a nice spa day! Here’s a quick look at the benefits:

| Benefits | Explanation |

|---|---|

| Vibration Control | Stops tools from shaking and helps them cut better. |

| Enhanced Tool Life | Longer-lasting tools mean less frequent replacements. Yay! |

| Less Machinery Wear | Saves money on repairs and keeps machines running smoothly. |

With these techniques, milling becomes smoother, faster, and way more fun! Who knew our machines could have so many tricks up their sleeves?

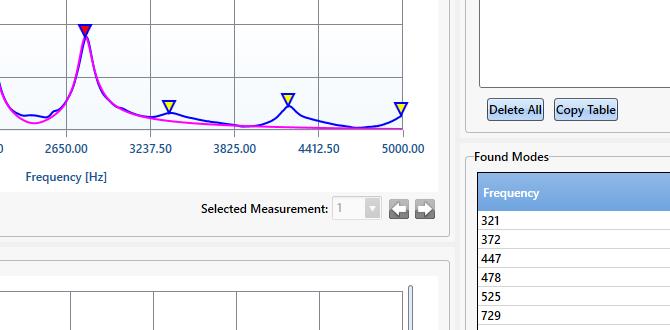

Key Parameters in Modal Analysis

Natural frequencies. Mode shapes. Damping ratios.In modal analysis, understanding key parameters is essential. Natural frequencies show how often a system vibrates. These are like a tuning fork’s tone—each tool sings a different note! Then we have mode shapes, the unique patterns of movement when vibrating. Think of these as dance moves; each tool has its own style. Lastly, damping ratios tell us how quickly vibrations fade away. It’s like a balloon losing air; some pop quickly, while others slowly deflate!

| Parameter | Description |

|---|---|

| Natural Frequencies | Vibration rates of the tool |

| Mode Shapes | Patterns of vibration |

| Damping Ratios | Speed at which vibrations decrease |

Case Studies

Successful applications in the industry. Lessons learned from modal analysis implementations.Many industries have found success using milling tool modal analysis techniques. These methods help identify issues early and improve tool performance. For example:

- Automakers used modal analysis to enhance engine parts. This reduced noise and improved efficiency.

- Aerospace companies applied these techniques to detect vibrations, leading to safer aircraft designs.

Key lessons from these cases include:

- Early detection of problems saves money.

- Regular analysis can extend tool life and improve quality.

With these insights, companies can make better decisions. This can lead to greater success and happier customers.

What are the benefits of modal analysis in milling tools?

Modal analysis improves tool performance, reduces the risk of failure, and saves costs by detecting issues early.

Challenges and Limitations

Common challenges in modal analysis. How to overcome limitations in milling applications.Modal analysis can be tricky! Common challenges include getting accurate data and dealing with machine vibrations. These vibrations can be a nuisance, like a pesky fly buzzing around while you try to focus. To overcome issues in milling applications, ensure proper calibration and use high-quality sensors. This helps in getting data everyone can trust. Here’s a quick table with some common challenges and clever fixes:

| Challenge | Solution |

|---|---|

| Inaccurate Measurements | Use reliable sensors and calibrate them often. |

| Machine Vibrations | Implement damping techniques to minimize effects. |

| Complex Structures | Break down models for easier analysis. |

Stay sharp and tackle these challenges! It’s like assembling a puzzle; once you fit the pieces together, everything makes sense.

Future Trends in Modal Analysis Techniques

Advances in technology. Predictions for future applications in milling tools.New technologies are changing how we do modal analysis. Exciting tools like advanced sensors and smart software are making this job easier and faster. In milling tools, we can expect more precise measurements and real-time analysis. These tools can detect problems before they happen, saving time and money. Here are some future predictions:

- Greater use of AI: Machines may learn from their past data.

- Improved accuracy: Sensors will detect issues with more detail.

- Faster tests: Machines will analyze data in seconds.

What new technologies will help modal analysis?

New technologies like AI and smart sensors will greatly improve modal analysis in the future.

Conclusion

In summary, milling tool modal analysis techniques help us understand how tools vibrate during use. This knowledge improves tool design and performance. By applying these techniques, you can enhance productivity and reduce wear. We encourage you to explore more about this topic, as it can positively impact your work in machining. Learning more will give you valuable insights!FAQs

Sure! Here Are Five Related Questions On The Topic Of Milling Tool Modal Analysis Techniques:Milling tool modal analysis helps us understand how milling tools move and vibrate. We can use special techniques to study this. By finding patterns, we can improve the tools and make them work better. It helps in making sure the tools last longer and cut accurately. Understanding these techniques is important for anyone working with mills.

Sure! Please provide the question you’d like me to answer.

What Are The Primary Objectives Of Conducting Modal Analysis On Milling Tools, And How Can It Improve Machining Performance?We do modal analysis on milling tools to understand how they move and vibrate. This helps us find the best way to use them. When we know how tools behave, we can avoid problems, like breaking or wearing out too soon. Better tools cut faster and make better shapes in our projects. This means we can do our work more easily and save time!

How Do Different Modal Analysis Techniques, Such As Experimental Modal Analysis (Ema) And Finite Element Analysis (Fea), Compare In Terms Of Accuracy And Applicability For Milling Tools?Experimental Modal Analysis (EMA) looks at real tools to see how they vibrate. It gives very accurate results. Finite Element Analysis (FEA) uses computer models to predict how tools behave. While FEA is helpful and faster, it might not always be as accurate as EMA. Both methods are useful for understanding milling tools, but EMA usually shows the real picture better.

What Role Does Vibration Analysis Play In Modal Analysis For Milling Tools, And What Tools Or Methods Are Commonly Used To Measure Vibrations During Milling?Vibration analysis helps us understand how milling tools shake and move while they work. This is important because it helps us make better tools and improve their performance. We can measure vibrations using special tools like sensors, accelerometers, or microphones. These tools record the vibrations so we can see how the tools behave while cutting materials. By studying this information, we can make our milling tools last longer and work better.

How Can The Modal Parameters Obtained From Modal Analysis Of Milling Tools Contribute To The Design Of More Efficient Cutting Tools And Improve Machining Outcomes?When we study milling tools, we can see how they move and vibrate. This is called modal analysis. By understanding their movements, we can design tools that cut better and last longer. Better tools help us make things faster and with fewer mistakes. Overall, it helps us create high-quality products.

What Challenges Are Typically Encountered During Modal Analysis Of Milling Tools, And What Strategies Can Be Implemented To Overcome These Challenges?When we study how milling tools shake and move, we face some problems. One challenge is that tools can be heavy and hard to hold still. Another issue is noise, which can hide important signals. We can fix these by using special machines to hold the tools steady and making sure our work area is quiet. This helps us see and understand the tool’s movements better.