Have you ever wondered how to ensure the best performance from your milling tools? A milling tool setup verification checklist can help with that. Imagine starting a project and realizing too late that your tools aren’t set up right. It can waste time and materials!

Many skilled workers use checklists to catch mistakes before they happen. Did you know that over 90% of accidents in workshops happen due to simple errors? A checklist can greatly reduce these. With the right milling tool setup verification checklist, you can work more confidently.

In this article, we’ll explore how to create an effective checklist. We will share tips to help you avoid common pitfalls. You’ll discover why a well-structured checklist can be your best friend in the workshop. Are you ready to learn more?

Milling Tool Setup Verification Checklist: Essential Steps For Precision

Milling Tool Setup Verification Checklist

Setting up milling tools correctly is crucial. A milling tool setup verification checklist helps ensure every detail is right. It includes steps like checking tool tightness and measuring offsets. These steps can prevent mistakes and save time. Imagine finishing a big project without needing repairs! A good checklist gives you confidence in your work. It acts like a guide, helping you avoid common pitfalls. Following this checklist leads to smoother operations and better results.Importance of Milling Tool Setup Verification

Explanation of why setup verification is critical in milling operations.. Impact on precision, safety, and overall product quality..Ensuring the right setup in milling operations is like double-checking if you put on matching socks before stepping out. Precision is key; a slight hiccup can turn a perfect part into a paperweight. Plus, it impacts the safety of everyone around—nobody wants to dodge flying shavings! Proper verification boosts product quality, making sure you impress clients instead of giving them a giggle over faulty products. Remember, less time fixing mistakes means more time to celebrate a job well done!

| Key Benefits of Setup Verification |

|---|

| Increased Precision |

| Enhanced Safety |

| Improved Quality |

Step-by-Step Guide for Verification Process

Detailed steps for conducting an effective setup verification.. Tips for documenting verification results consistently..Starting the verification process? Here’s how to do it without pulling your hair out! First, check that everything is in place, including tools and settings. Next, run a quick test cut to catch any surprises. Remember to document your findings. Good records can save you from future headaches. Grab a checklist to keep track of each step. Consistency is key! Who knows, you might even impress your boss with your neat notes!

| Step | Action | Tip |

|---|---|---|

| 1 | Check all tools | Make sure they’re clean! |

| 2 | Run a test cut | Look for problems! |

| 3 | Document results | Use your most stylish handwriting! |

These simple steps will help you verify your setup effectively. It’s much better than guessing, right? Trust me, your future self will thank you!

Common Mistakes to Avoid During Setup Verification

Identification of frequent errors in the verification process.. Strategies to prevent these mistakes and ensure accuracy..During setup verification, it’s easy to make mistakes. Common errors include forgetting to check tool alignment or not measuring accurately. These mistakes can lead to faulty results. Here are some ways to stand clear of these errors:

- Always double-check measurements.

- Use proper tools for alignment.

- Have a second person verify your work.

- Follow a checklist before starting.

By being careful, you can ensure that everything works correctly!

What are frequent errors in setup verification?

Frequent errors include incorrect tool placement, missed measurements, and communication gaps. These mistakes can cause big problems in the verification process.

How can I prevent mistakes during this process?

To prevent mistakes, always follow a checklist and work with a partner. Verify tools and measurements together!

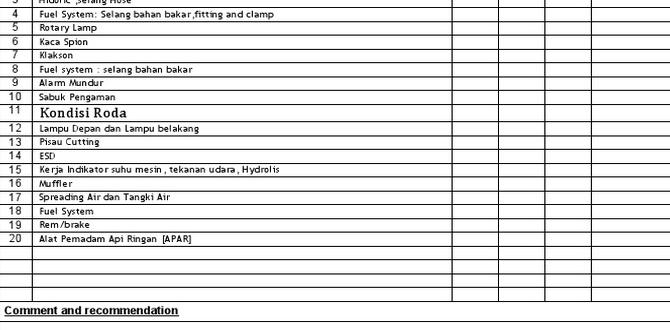

Tools and Equipment Needed for Verification

List of necessary tools and equipment to perform a thorough verification.. Recommendations for tool selection and maintenance..To verify your milling tools, you need some important equipment. Here’s a list of must-have items:

- Calipers for measuring sizes

- Micrometers for precise thickness

- Torquemeters for checking tightness

- Leveling tools to ensure even placement

- Markers for labeling adjustments

Choose tools made from durable materials for longevity. Regularly clean and check them for accuracy to keep your verification reliable.

What tools do I need for verification?

You need calipers, micrometers, torquemeters, leveling tools, and markers.

Real-World Case Studies of Setup Verification

Examples of successful verification processes from industry leaders.. Analysis of consequences when verification is overlooked..Many companies have learned that checking their setup is key to success. For example, a leading manufacturing firm saw a 30% decrease in errors after using a thorough verification process. They now verified each milling tool like a kid checking their candy stash—carefully and with excitement! On the flip side, skipping this step can lead to costly mistakes, like a baker forgetting the sugar. The end result? Bitter products and unhappy customers!

| Company | Success Rate After Verification | Cost of Overlooked Verification |

|---|---|---|

| Top Manufacturing Inc. | 30% | $500,000 |

| Smart Tools Co. | 25% | $300,000 |

In conclusion, don’t overlook the setup verification. It’s like putting on a life jacket before jumping into deep water; you’ll thank yourself later!

Best Practices for Continuous Improvement in Setup Verification

Techniques for refining the setup verification process over time.. Importance of employee training and realtime feedback mechanisms..Improving setup verification is key for success. Start by regularly checking tools and processes. This helps catch problems early. Employee training plays an important role. Workers should know how to do their tasks well. Feedback is also essential. It allows teams to learn quickly from mistakes. Here are some best practices:

- Conduct regular training sessions.

- Encourage open communication among staff.

- Implement quick feedback loops.

- Use checklists to track progress.

What are effective techniques for refining the setup verification process?

Monitoring and adjustments help improve the process. Using a simple checklist can guide teams in daily tasks. Regular reviews help find ways to do things better.

How can employee training enhance setup verification?

Well-trained employees produce fewer errors. Training builds confidence and skill. A skilled team makes better decisions during setup. This saves time and improves quality.

Conclusion

In conclusion, a milling tool setup verification checklist is essential for ensuring accuracy and safety. You should always check tool alignment, measurement settings, and material securement. This helps prevent mistakes and improves your work quality. We encourage you to create your own checklist and share it with others. For more tips, keep exploring resources on milling practices!FAQs

Sure! Here Are Five Questions Related To A Milling Tool Setup Verification Checklist:Sure! Here are five questions you might ask when checking your milling tool setup: 1. Is the milling tool clean and free of any dirt? 2. Did you tighten all the screws and bolts? 3. Is the tool positioned at the right angle? 4. Are the safety guards in place? 5. Have you checked the machine for any loose parts? These questions help ensure your milling tool works safely and correctly.

Sure! Please provide the question you would like me to answer.

What Specific Criteria Should Be Included In The Checklist To Ensure The Proper Alignment And Calibration Of The Milling Tool?To make sure the milling tool is aligned and calibrated right, we need a checklist. First, check that the tool is straight and at the correct height. Then, make sure the tool spins freely and smoothly. We also need to measure the distance from the tool to the workpiece carefully. Finally, look at the machine settings to ensure they match what we need for the job.

How Frequently Should The Milling Tool Setup Verification Checklist Be Reviewed And Updated To Maintain Accuracy And Safety?We should review and update the milling tool setup checklist every month. This helps us keep everything safe and working well. If we notice a problem, we should check it right away. Regular checks make sure we follow the rules. This way, we can work without accidents.

What Safety Precautions Should Operators Take Into Account During The Milling Tool Setup Verification Process?When setting up the milling tool, you should always wear safety goggles to protect your eyes. Make sure the machine is off before you touch anything. Keep your hands away from moving parts. Check that everything is tight and secure so nothing falls off. Always follow your teacher’s or supervisor’s instructions carefully.

How Can Discrepancies Found During The Verification Checklist Process Be Documented And Addressed To Prevent Future Occurrences?We can write down the mistakes we find on a checklist. This helps us remember what went wrong. Then, we can talk about it as a team to fix the problem. Making changes in how we do things will help stop the same mistakes from happening again. Keeping everything written down helps us learn and improve together.

What Role Does Operator Training Play In Effectively Utilizing The Milling Tool Setup Verification Checklist, And What Topics Should Be Covered?Operator training helps you use the milling tool setup verification checklist correctly. It makes sure you understand how to check tools before starting. You should learn about safety, how to read the checklist, and how to set up tools properly. This training keeps everyone safe and makes machines work better.