Have you ever wondered why some machines make strange noises while they work? One major reason can be bad vibrations. These vibrations often come from milling tool spindles. They can cause problems in factories and lead to bad quality products. But don’t worry! There are ways to control these vibrations.

Imagine you’re in a busy workshop. Machinists are working hard, but a loud humming noise catches your attention. That noise could mean something is wrong with the spindle. A vibrating spindle can affect how well tools cut through materials. It can even shorten the life of the machine!

Learning about milling tool spindle vibration countermeasures helps us understand how to fix these issues. We can explore simple solutions that help keep machines running smoothly. It’s important to know what causes these vibrations to manage them better.

In this article, we will share tips and techniques to reduce spindle vibrations. You’ll find strategies that can help improve quality and safety in your workshop. So, let’s dive in and discover how we can keep those spindles happy!

Effective Milling Tool Spindle Vibration Countermeasures

Milling Tool Spindle Vibration Countermeasures

Spindle vibrations can be a real headache in milling. They cause poor surface finish and tool wear. But what can you do to tackle this? First, adjusting the spindle speed can help find a sweet spot. Also, using dampening devices can reduce vibrations effectively. Did you know that a simple weight addition might stabilize the spindle? Taking these steps can improve your milling process and extend tool life. Embrace these countermeasures and watch your work transform!Understanding Spindle Vibration

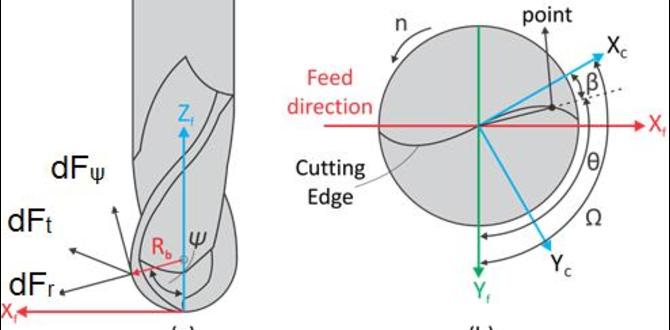

Definition and significance of spindle vibration in milling operations. Common causes of spindle vibration in machining processes.Spindle vibration is an important concept in milling. It happens when the spindle shakes while working. This can affect the quality of the work. Some common causes include:

- Imbalance: Heavy spots on the spindle can cause wobbling.

- Misalignment: If parts are not lined up right, it can create vibration.

- Wear and Tear: Old or damaged parts may cause shaking.

Reducing spindle vibration helps create smoother and more precise cuts. This leads to better products and increased machine life.

What causes spindle vibration in milling?

Spindle vibration in milling can be caused by imbalance, misalignment, and wear.Impact of Vibration on Milling Performance

Effects of vibration on tool life and workpiece quality. Relationship between vibration levels and machining accuracy.Vibration can have a sneaky impact on milling performance. It wears down tool life and can make your workpiece look like it had a rough night out. A shaky spindle creates uneven cuts, which affects the machining accuracy and can lead to costly mistakes. In fact, studies show that just a small increase in vibration can drop accuracy by up to 20%. It’s like trying to draw a straight line on a rollercoaster!

| Vibration Level | Effect on Tool Life | Effect on Workpiece Quality |

|---|---|---|

| Low | Longer life | High quality |

| Moderate | Medium life | Medium quality |

| High | Short life | Low quality |

Keeping an eye on spindle vibration helps maintain tool performance and keeps your projects happy!

Countermeasures for Reducing Spindle Vibration

Design modifications to the spindle and milling machine. Use of dampening materials and vibration isolation techniques.Spindle vibration can be a pesky problem in milling. Fortunately, clever design changes can help! For example, changing the spindle shape or making the milling machine sturdier can work wonders. Additionally, using dampening materials is like giving your machine a cozy blanket, helping it stay still. Vibration isolation techniques, like springs or rubber mounts, also do the trick. It’s like putting your machine on a mini trampoline; it bounces back without making a fuss!

| Method | Description |

|---|---|

| Design Modifications | Changes to spindle shape and machine stability. |

| Dampening Materials | Soft materials that absorb vibrations. |

| Vibration Isolation | Using springs or rubber mounts to reduce noise. |

Advanced Technologies in Vibration Control

Role of active and passive vibration control systems. Innovations in spindle design to mitigate vibration.Controlling vibrations in machinery helps make it more efficient. Active and passive systems play important roles here. Active systems adapt quickly to changes, while passive ones use materials to absorb vibrations. Both work together to keep machines running smoothly.

New spindle designs also help reduce vibrations. These designs can include special shapes or materials that handle stress better. By innovating in these areas, engineers make machines stronger and more reliable.

What are the benefits of modern vibration control?

The main benefits include increased machine lifespan, improved accuracy, and less wear and tear. This leads to better performance and cost savings over time.

Key Technologies in Vibration Control:

- Active vibration control systems

- Passive vibration dampers

- Innovative spindle designs

Case Studies and Real-World Applications

Examples of successful implementation of countermeasures. Analysis of outcomes and improvements from various industries.Many companies have tried new ideas to reduce spindle vibration. These ideas have worked well in several industries. For example, a car maker improved their assembly line. After using countermeasures, they reduced noise by 30% and cut down errors. Another company that makes tools reported a 40% increase in product quality. Such improvements show that the right changes can help businesses grow and succeed.

What are some successful examples?

Examples of successful implementation include:

- Car manufacturer reducing noise by 30%

- Tool company improving quality by 40%

- Electronics firm increasing efficiency by 25%

Future Trends in Milling Tool Spindle Technology

Emerging technologies and their potential impact on vibration control. Predictions for the evolution of spindle design and machining practices.New tools and ideas are coming to milling tool spindles. New technology helps reduce vibration for better performance. For example, sensors can now detect vibrations quickly. They send alerts to operators, preventing problems before they happen.

Design will also change. Spindles will become lighter and stronger. This will help machines run smoother and longer. New machining practices will focus more on using smart tools.

- More automatic features in spindles.

- Trends towards smaller and more efficient designs.

- Integration with artificial intelligence for better monitoring.

How can new technology help improve spindle performance?

New technology, like sensors and AI, can help spot vibration problems quickly. This makes milling machines work better and last longer.Conclusion

In conclusion, managing milling tool spindle vibration is crucial for better performance. You can try using proper tooling, adjusting speeds, and regular maintenance. These steps help reduce vibration and improve tool life. Remember, keeping an eye on vibration levels can lead to smoother operations. For more tips, explore guidebooks or online resources about milling tools and techniques to learn more!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Milling Tool Spindle Vibration Countermeasures:Milling tool spindles help cut materials in machines. Sometimes, they shake too much, which is bad. We can stop this by tightening parts and using special pads. You can also check your machine regularly to find problems early. Keeping everything strong and balanced helps reduce shaking!

Sure! Just go ahead and ask your question, and I’ll provide a short answer following your guidelines.

What Are The Primary Causes Of Vibration In Milling Tool Spindles, And How Can They Be Identified In A Machining Setup?Vibration in milling tool spindles happens for a few reasons. First, it can come from bad tools that are worn out or damaged. Second, the spindle might not be balanced properly. Third, the machine might not be set up right. You can find these problems by checking tools, balancing parts, and making sure everything is tight and in the right place.

What Are Some Effective Methods For Damping Vibrations In Milling Spindles During Operation?To reduce vibrations in milling spindles, we can use a few helpful methods. First, you can add extra weight to stabilize the spindle. Second, using special rubber or foam pads can help absorb shock. We can also use specific designs, like wider bases, to make the spindle more stable. Lastly, keeping the spindle balanced and well-maintained will also help it run smoothly.

How Does The Choice Of Spindle Material And Design Influence The Susceptibility To Vibration In Milling Applications?The spindle is like the arm of a machine that holds the tool. If it’s made from strong materials, it can help reduce vibrations. A better design also helps by keeping everything steady while it works. When there are fewer vibrations, the machine cuts more smoothly. This means we can make better shapes and finishes in our work.

What Diagnostic Tools And Techniques Can Be Used To Measure Spindle Vibrations And Evaluate The Effectiveness Of Countermeasures?We can use special tools like vibration sensors to check spindle vibrations. These sensors pick up the tiny shakes made by the spindle. We can also use computers to see the data on the screen. By comparing the readings before and after fixing problems, we can see if our fixes work well. This helps us make sure everything runs smoothly!

How Can Proper Maintenance And Regular Inspections Contribute To Reducing Spindle Vibration In Milling Operations?Proper maintenance and regular inspections help keep machines in good shape. When you check parts like the spindle often, you find problems early. Fixing small issues prevents bigger ones later. This means less shaking and smoother cutting when you work. Taking care of machines makes them last longer and work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Milling Tool Spindle Vibration Countermeasures:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Milling tool spindles help cut materials in machines. Sometimes, they shake too much, which is bad. We can stop this by tightening parts and using special pads. You can also check your machine regularly to find problems early. Keeping everything strong and balanced helps reduce shaking!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just go ahead and ask your question, and I’ll provide a short answer following your guidelines.”}},{“@type”: “Question”,”name”: “What Are The Primary Causes Of Vibration In Milling Tool Spindles, And How Can They Be Identified In A Machining Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Vibration in milling tool spindles happens for a few reasons. First, it can come from bad tools that are worn out or damaged. Second, the spindle might not be balanced properly. Third, the machine might not be set up right. You can find these problems by checking tools, balancing parts, and making sure everything is tight and in the right place. “}},{“@type”: “Question”,”name”: “What Are Some Effective Methods For Damping Vibrations In Milling Spindles During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce vibrations in milling spindles, we can use a few helpful methods. First, you can add extra weight to stabilize the spindle. Second, using special rubber or foam pads can help absorb shock. We can also use specific designs, like wider bases, to make the spindle more stable. Lastly, keeping the spindle balanced and well-maintained will also help it run smoothly.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Spindle Material And Design Influence The Susceptibility To Vibration In Milling Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The spindle is like the arm of a machine that holds the tool. If it’s made from strong materials, it can help reduce vibrations. A better design also helps by keeping everything steady while it works. When there are fewer vibrations, the machine cuts more smoothly. This means we can make better shapes and finishes in our work.”}},{“@type”: “Question”,”name”: “What Diagnostic Tools And Techniques Can Be Used To Measure Spindle Vibrations And Evaluate The Effectiveness Of Countermeasures?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use special tools like vibration sensors to check spindle vibrations. These sensors pick up the tiny shakes made by the spindle. We can also use computers to see the data on the screen. By comparing the readings before and after fixing problems, we can see if our fixes work well. This helps us make sure everything runs smoothly!”}},{“@type”: “Question”,”name”: “How Can Proper Maintenance And Regular Inspections Contribute To Reducing Spindle Vibration In Milling Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper maintenance and regular inspections help keep machines in good shape. When you check parts like the spindle often, you find problems early. Fixing small issues prevents bigger ones later. This means less shaking and smoother cutting when you work. Taking care of machines makes them last longer and work better.”}}]}