Have you ever wondered how machines cut through tough materials? The secret often lies in a crucial factor: milling tool torque control. This smooth operation ensures the tool works effectively and safely.

Imagine a chef slicing vegetables with a perfectly balanced knife. The right pressure helps cut cleanly. Similarly, in milling, proper torque control allows for precise cuts without damaging the tool or the material. Without it, things can go wrong quickly!

Fun fact: Did you know that improper torque can cause tools to wear out fast? This can mean more downtime and added costs. That’s why understanding milling tool torque control is vital for anyone in manufacturing.

So, how do we ensure that tools operate at just the right torque during the job? In this article, we will explore the importance of torque control and how it impacts milling operations. Get ready to dig deeper into the exciting world of milling!

Milling Tool Torque Control During Operations: Essential Insights

Milling Tool Torque Control

Milling tool torque control is crucial for smooth operations. It ensures tools don’t slip or break during cutting. Have you ever wondered why some tools last longer than others? Proper control of torque can make a big difference. By adjusting torque, operators improve efficiency and accuracy. This can reduce waste and save time. Imagine cutting materials without fear of damaging your tool. With the right knowledge, you can enhance your milling experience and get the best results.Understanding Torque in Milling Operations

Definition of torque in the context of milling.. Importance of torque in achieving precision and efficiency..Torque is like the strength behind your milling tool. It helps the tool turn and cut materials properly. Think of it as a superhero power that makes milling machines work smoothly. Strong torque helps in achieving precision and makes processes more efficient. Without enough torque, the tool might slip or wear out quickly, ruining your hard work. So, torque is key to success on the milling battlefield!

| Aspect | Importance |

|---|---|

| Precision | Ensures accurate cuts and shapes. |

| Efficiency | Reduces time and material waste. |

Factors Influencing Milling Tool Torque

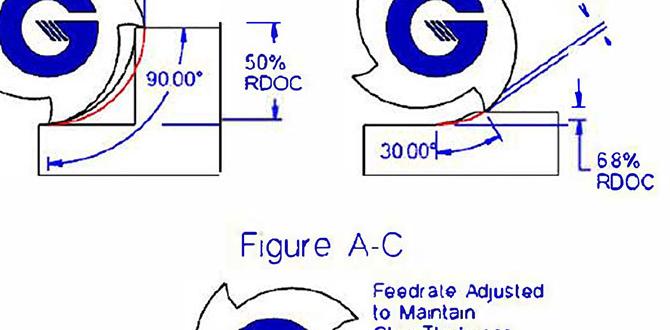

Tool material and design considerations.. Machine settings and environmental influences..Milling tool torque can change based on many factors. First, the tool’s material and design play a big role. For example, tools made of hard materials last longer. Their shape affects how well they cut. Second, machine settings also matter. Different speeds and feed rates influence torque levels. Lastly, the environment can make a difference. Heat and vibration can impact operations too. Keeping these in mind helps in achieving the best results.

What affects milling torque?

Tool material, design, machine settings, and environmental factors all influence milling torque.

Key Factors Include:

- Tool Material: Harder materials improve durability.

- Tool Design: Aerodynamics help with cutting efficiency.

- Machine Settings: Speed and feed rates must be optimized.

- Environmental Influences: Temperature and vibration can change performance.

Best Practices for Torque Control

Recommended torque values for different materials.. Techniques for monitoring and adjusting torque in realtime..Using the right torque values is key to good milling. Different materials need different amounts. Here are some general values:

- Wood: 10-20 Nm

- Plastic: 15-25 Nm

- Metal: 20-50 Nm

To monitor torque while working, you can use special tools that show real-time data. This helps you adjust quickly if needed. Keeping an eye on your torque helps prevent mistakes and makes your work smoother.

Why is torque control important?

Torque control helps machines work efficiently and safely. Ensuring proper torque prevents damage and keeps products accurate. A small change can have a big effect!

Common Challenges in Torque Management

Identifying issues related to over and undertorquing.. Solutions to mitigate torquerelated problems..Managing torque during milling operations can be tricky. Problems like over-torquing and under-torquing can arise. Over-torquing can damage tools and materials. Under-torquing may lead to loose assemblies. Here are some tips to solve torque issues:

- Regularly check tool condition.

- Use torque wrenchesaccurately.

- Train operators on proper techniques.

- Monitor temperature changes.

Monitoring torque levels helps maintain quality and safety in operations.

What are the effects of poor torque management?

Poor torque management can cause tool failure, unnecessary wear, and assembly problems. Keeping track of torque levels is vital for successful operations.

Case Studies on Effective Torque Control

Examples of successful torque control implementations in industry.. Analysis of results and outcomes from best practices..Many industries have found success with effective torque control. For example, a car manufacturer improved their assembly process. They used precise torque tools, resulting in fewer mistakes and better quality. Another case involves a wind turbine company. They reduced energy costs by choosing the right tools for torque control.

Here are some proven outcomes:

- Lower production errors

- Increased equipment lifespan

- Improved worker safety

These examples show how smart torque control can lead to great results. Adopting best practices helps companies stay ahead.

How can torque control impact production?

Effective torque control can enhance efficiency, reduce costs, and improve product quality in manufacturing.

Future Trends in Milling Tool Torque Control

Emerging technologies and their potential impact.. Predictions for the evolution of torque management in milling..Exciting new technologies are changing how we control milling tool torque during operations. Smart sensors and data analysis help machines work better and safer. With AI taking the lead, we can predict when a tool needs adjustments. This will help avoid mistakes. Here are some predictions for the future:

- More automation will make torque management easier.

- Real-time data will improve decision-making.

- Safety will be the top priority with smart tools.

In summary, the future of torque control looks bright. We can expect tools to be smarter and more efficient.

What is the role of emerging technologies in torque control?

Emerging technologies like AI and smart sensors improve milling tool torque control. They allow for real-time adjustments, making operations smoother and safer.

Conclusion

In summary, managing milling tool torque is essential for smooth operations. It helps prevent damage and maintains accuracy. You should regularly check your tools and adjust settings as needed. Understanding torque can improve your projects and boost your skills. To learn more, explore tutorials or guides on milling techniques. With practice, you can master your milling tasks!FAQs

What Are The Key Factors That Influence Torque Levels During Milling Operations?The key factors that influence torque levels in milling are the type of material being cut, the shape of the tool, and how fast it spins. If the material is hard, it can take more power to cut through it. A sharper tool usually cuts better and needs less energy. Lastly, spinning the tool faster can change how much torque is needed. So, we need to think about all these things to work efficiently.

How Can Real-Time Torque Monitoring Improve The Efficiency And Precision Of Milling Processes?Real-time torque monitoring helps us see how much force the machine is using while cutting. When we know this information, we can make quick changes to keep everything running smoothly. This helps us work faster and makes our cuts more accurate. By watching the torque, we can also avoid mistakes and keep our tools in good shape. Overall, it makes milling better and helps us create better products.

What Techniques Are Available For Controlling Torque During High-Speed Milling Operations?To control torque in high-speed milling, we can use several techniques. First, we can adjust the speed of the milling tool to fit the material. We can also change how much the tool cuts into the material. Using the right cutting tools and keeping them sharp helps too. Lastly, we can use special software to monitor and control the process.

How Do Different Milling Tool Geometries Affect Torque Requirements And Overall Machining Performance?Different shapes of milling tools can change how much force we need to use when cutting materials. For example, a tool with sharp edges usually cuts better and needs less power. On the other hand, a tool with a flat shape might struggle and require more force. This means that the right tool shape can help us work faster and make our machines last longer. Choosing the best geometry helps us get good results while using less energy.

What Role Does Cnc Programming Play In Managing Torque Control During Milling Operations?CNC programming helps our machines know how much power to use while cutting. When we mill, or shape, materials, we need to be careful with the force, called torque. Good programming makes sure the machine uses just the right amount of torque. This helps us avoid damage to the tool and the material. It also makes our work more accurate and safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors That Influence Torque Levels During Milling Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The key factors that influence torque levels in milling are the type of material being cut, the shape of the tool, and how fast it spins. If the material is hard, it can take more power to cut through it. A sharper tool usually cuts better and needs less energy. Lastly, spinning the tool faster can change how much torque is needed. So, we need to think about all these things to work efficiently.”}},{“@type”: “Question”,”name”: “How Can Real-Time Torque Monitoring Improve The Efficiency And Precision Of Milling Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Real-time torque monitoring helps us see how much force the machine is using while cutting. When we know this information, we can make quick changes to keep everything running smoothly. This helps us work faster and makes our cuts more accurate. By watching the torque, we can also avoid mistakes and keep our tools in good shape. Overall, it makes milling better and helps us create better products.”}},{“@type”: “Question”,”name”: “What Techniques Are Available For Controlling Torque During High-Speed Milling Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To control torque in high-speed milling, we can use several techniques. First, we can adjust the speed of the milling tool to fit the material. We can also change how much the tool cuts into the material. Using the right cutting tools and keeping them sharp helps too. Lastly, we can use special software to monitor and control the process.”}},{“@type”: “Question”,”name”: “How Do Different Milling Tool Geometries Affect Torque Requirements And Overall Machining Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different shapes of milling tools can change how much force we need to use when cutting materials. For example, a tool with sharp edges usually cuts better and needs less power. On the other hand, a tool with a flat shape might struggle and require more force. This means that the right tool shape can help us work faster and make our machines last longer. Choosing the best geometry helps us get good results while using less energy.”}},{“@type”: “Question”,”name”: “What Role Does Cnc Programming Play In Managing Torque Control During Milling Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC programming helps our machines know how much power to use while cutting. When we mill, or shape, materials, we need to be careful with the force, called torque. Good programming makes sure the machine uses just the right amount of torque. This helps us avoid damage to the tool and the material. It also makes our work more accurate and safe.”}}]}