Imagine a busy workshop where machines hum and tools spin. In such an environment, milling tools are essential. But what happens when these tools wear out? The truth is, worn tools can ruin a project. They can cause bad cuts or even damage materials. That’s why detecting tool wear is so important.

Have you ever wondered how factories keep track of this problem? Well, they use something called milling tool wear detection automation. This clever technology can spot when a tool is getting dull. It helps workers know when to change tools before they cause issues.

Let’s take a closer look at this technology. It’s changing how we think about milling. Automating tool wear detection not only saves time but also keeps projects running smoothly. Together, let’s explore how this innovation can help everyone in the manufacturing world!

Milling Tool Wear Detection Automation For Enhanced Precision

Milling Tool Wear Detection Automation

Milling tools are essential in many factories. But did you know that knowing when they wear out can save money? Automated wear detection looks at tool condition in real-time. This tech helps avoid costly mistakes. Just imagine a tool that warns you before it breaks! Regular checks can lower downtime, boost productivity, and enhance safety. Many industries adopt this innovation for better performance. With automation, your tools can work smarter, not harder!Understanding Tool Wear in Milling Operations

Definition of tool wear and its significance in milling.. Types of tool wear and their impact on milling efficiency..Tool wear happens when cutting tools lose their sharpness over time. This is important in milling because it can affect how well a machine works and how smooth the surfaces of materials become. When tools wear out, they can make cuts that are not clean and can damage the workpieces.

There are different types of tool wear, each impacting efficiency:

- Flank wear: This type happens on the side of the tool and can lead to poor cutting.

- Crater wear: It appears on the tool face and makes it difficult for the tool to cut.

- Edge chipping: This is when small pieces break off the tool, causing rough edges.

Each type of wear can slow down production and increase costs. Keeping an eye on tool wear helps machines run smoothly and saves money.

What is milling tool wear detection automation?

Milling tool wear detection automation uses technology to monitor tool wear in real-time. This helps machines stay efficient and cuts costs by predicting when a tool needs replacing.

Importance of Wear Detection in Milling Tool Performance

Effects of undetected wear on product quality and production costs.. Benefits of early wear detection for operational efficiency..Detecting wear in milling tools is like finding out your toy is broken before it stops working. If wear goes unnoticed, it can lower product quality and boost production costs. Imagine getting a lopsided cookie because your cookie cutter was worn out! This leads to waste and unhappy customers. On the bright side, catching wear early can save money and keep things running smoothly, making operations more efficient. It’s like spotting a flat tire before your road trip!

| Effects of Undetected Wear | Benefits of Early Detection |

|---|---|

| Lower product quality | Improved operational efficiency |

| Increased production costs | Cost savings |

| Waste of materials | Fewer customer complaints |

Data Analysis Techniques for Tool Wear Monitoring

Use of machine learning and AI in predicting tool wear.. Realtime data processing and its applications in automation..Using machine learning and AI to detect tool wear is like having a superhero for your milling equipment. It helps predict when tools will wear down, saving money and time. Imagine a tool that whispers, “Hey, I need a break!” Real-time data processing is the secret sauce. It collects info and updates instantly, making automation smoother than butter. Everyone loves a good gadget that works smart, not hard!

| Technique | Benefit |

|---|---|

| Machine Learning | Predicts wear patterns |

| Real-Time Processing | Immediate updates |

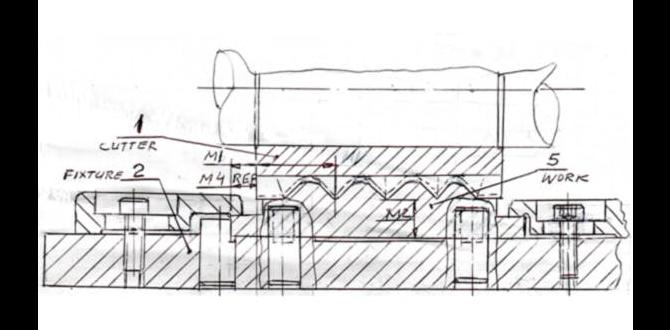

Integration of Wear Detection Systems with CNC Machines

Steps for integrating wear detection systems in existing CNC setups.. Benefits of seamless integration for enhanced productivity..Setting up wear detection systems with CNC machines can improve your work. First, test the existing machines for compatibility. Next, install the wear detectors and connect them to the CNC’s software. After that, run a few tests to ensure everything works well.

Benefits of this setup include:

- Increased efficiency: Catching wear early saves time and resources.

- Better quality: Tools stay sharp, which means better products.

- Cost savings: Reduced tool replacement costs lead to saving money.

Incorporating wear detection helps keep machines running smoothly. This leads to less downtime and swiftly completed projects. More productivity means your business can grow.

How do wear detection systems work with CNC machines?

They monitor tool wear in real-time, sending alerts before tools get dull.

Case Studies of Successful Wear Detection Implementation

Examples from industries that improved outcomes through automation.. Key takeaways from successful tool wear detection implementations..Many industries have stepped up their game with wear detection automation, leading to impressive results. For instance, a car manufacturing plant used smart sensors to track tool wear. They cut costs by 25% and increased production speed. Another company, making electronic components, boosted product quality by 30% using similar tech. Key lessons from these successes show that timely wear alerts save money and improve efficiency. Remember, smart tools make happy workers—who wants to deal with unexpected breakdowns?

| Industry | Improvement | Key Takeaway |

|---|---|---|

| Automotive | 25% Cost Savings | Timely alerts are essential. |

| Electronics | 30% Quality Boost | Invest in smart tools! |

Challenges and Considerations in Implementing Automated Systems

Common obstacles in tool wear detection automation.. Best practices to overcome challenges and maximize success..Automating tool wear detection comes with its own set of bumps in the road. One big challenge is getting the right sensors for accurate readings. Poor sensors can be like trying to play hide and seek with a ghost—frustrating! Another obstacle is data overload. There’s so much information that it can make your head spin. To tackle these issues, start small with pilot tests and gradually ramp up. This way, you can spot problems early and make adjustments. Use a systematic approach to monitor and fine-tune your system.

| Challenges | Best Practices |

|---|---|

| Poor sensor performance | Choose quality sensors |

| Data overload | Start with pilot tests |

| Integration issues | Plan system compatibility |

By focusing on these points, success is not just a dream but something you can actually build. Remember, every great journey starts with a single step—unless you trip over the first one!

Future Trends in Milling Tool Wear Detection Technology

Emerging technologies that could shape the future of tool wear detection.. Predictions on how automation will evolve in milling processes..New technologies play a big role in improving how we detect tool wear. Brands are exploring smart sensors. These can send alerts about tool conditions instantly. Another exciting trend is machine learning. It can predict tool failure based on data. Automation is also advancing. Milling machines will get even smarter. They might adjust themselves without human help! Imagine how much easier that will make work!

- Smart sensors: Detect wear in real-time.

- Machine learning: Predict tool problems before they start.

- Automated adjustments: Machines change settings on their own.

What is the future of milling tool wear detection?

The future lies in smart technology and automation that makes work easier and safer.

Conclusion

In conclusion, milling tool wear detection automation helps improve machine efficiency and product quality. It saves time and reduces costs by catching wear early. You can learn more about automated systems to enhance your work. Consider researching tools that best fit your needs. By adopting these technologies, we can work smarter and achieve better results together!FAQs

Here Are Five Questions Related To Milling Tool Wear Detection Automation:Sure! Here’s a short answer for you: Automatic tools can help us see when a milling tool is wearing out. This makes it easier to fix or replace them on time. By knowing this, we can make better parts and save money. Using machines that watch tools helps us work faster and better. It’s like having a robot friend who tells us when our tools need help!

Sure! Please provide the question you want me to answer.

What Are The Most Effective Methods For Monitoring Tool Wear In Milling Operations Using Automation?We can monitor tool wear in milling by using special sensors and cameras. These tools help us see how much a cutting tool is wearing down. We can set up computers to take regular pictures and measurements. This way, we know when to change the tool before it breaks. Using automation makes it faster and easier to keep everything working well.

Of course! Please go ahead and ask your question.

How Can Machine Learning Algorithms Be Integrated Into Milling Tool Wear Detection Systems To Improve Accuracy And Predictive Maintenance?We can use machine learning to help us know when a milling tool is wearing out. First, we collect data from the tools while they work. Then, we teach the computer to look at this data and find patterns. When the computer learns these patterns, it can predict when a tool might need repair. This makes it easier for us to keep everything running smoothly!

Sure! Please provide the question you want me to answer.

What Types Of Sensors (E.G., Vibration, Acoustic Emission, Temperature) Are Commonly Used In Automated Systems For Detecting Milling Tool Wear, And How Do They Work?In automated systems, we often use sensors like vibration, acoustic emission, and temperature to check if milling tools are wearing out. Vibration sensors feel tiny movements in the tool as it works. Acoustic emission sensors listen for sounds that tools make when they get damaged. Temperature sensors measure how hot the tool gets; high heat can mean it’s wearing down. All of these sensors help us know when to change the tool before it breaks.

Sure! Please provide me with the question you’d like me to answer, and I’ll be happy to help.

How Does Real-Time Data Analysis Play A Role In Identifying Tool Wear Patterns, And What Software Solutions Are Available For This Purpose?Real-time data analysis helps us see how tools wear out while they work. It collects information quickly and shows patterns. This way, we can tell when a tool needs replacing without waiting. There are software tools like CAD (Computer-Aided Design) and specialized monitoring programs to help us with this. These tools make it easier for us to keep our machines running smoothly.

Sure! Please provide the question you’d like me to answer.

What Are The Key Challenges In Implementing Automated Tool Wear Detection Systems In Existing Milling Operations, And How Can They Be Overcome?A key challenge is that old machines may not have the right sensors. We can fix this by upgrading the machines or adding sensors. Another challenge is that people might not trust the new system. To help, we can offer training so everyone feels confident using it. Finally, we need to make sure the new system works well with the old processes, so planning is important.