Imagine building a model airplane. You need the right tools to make it look perfect. Have you ever thought about how important the right milling tool is for such projects? A milling tool with interchangeable heads can change everything!

This amazing tool lets users switch heads easily. Each head serves a different purpose. This way, you can get the job done quickly and accurately. Did you know that many people use these tools in their workshops? They can cut, shape, and carve materials like wood or metal, making them super useful.

Working with a milling tool like this is fun. You can explore and create new designs without worrying about using the wrong tool. Have you ever wanted to try a special project? With a milling tool that changes heads, you can dive into creativity like never before!

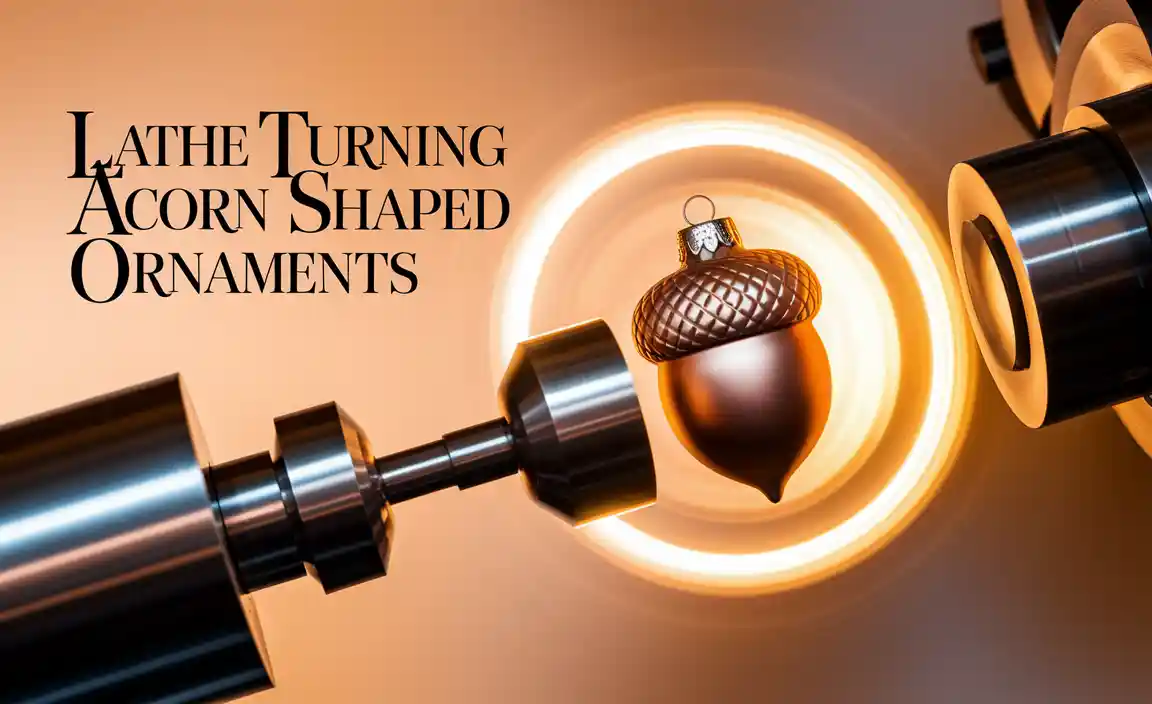

Milling Tool With Interchangeable Heads: Versatile Solutions For Precision Engineering

Milling Tool with Interchangeable Heads

Milling tools with interchangeable heads offer amazing versatility for woodworking and metalworking tasks. Instead of buying multiple tools, you can switch heads to meet different needs. Imagine tackling various projects with a single tool! Each head works like a special key for different jobs, making it easy to handle complex shapes or finishes. This design saves money and space in your workshop. Plus, they are simple to use, even for beginners. Wouldn’t it be cool to change your tool’s function in seconds?What is a Milling Tool with Interchangeable Heads?

Definition and function of milling tools. Explanation of interchangeable heads and their benefits.A milling tool is a special gadget used to shape materials like wood or metal. Think of it as a magic wand for craftsmen! It spins around and cuts away bits of the material, forming the perfect shape. Some milling tools come with interchangeable heads. This means you can swap out the cutting part for different tasks. Why is this cool? Because it saves time and money! You won’t need to buy a whole new tool—just change the head! It’s like having many tools in one!

| Feature | Benefit |

|---|---|

| Interchangeable Heads | Easier to switch for different jobs |

| Cost-Effective | No need for multiple tools |

| Versatile | Works on various materials |

Advantages of Using Interchangeable Heads

Costeffectiveness and reduced tool inventory. Enhanced versatility for different applications.Using interchangeable heads for milling tools is smart and saves money. Instead of buying many tools, you can switch the heads. This is cost-effective and cuts down on tool clutter. Think of it like having a Swiss Army knife for your workshop! Each head can handle different jobs, making your tool more versatile. You can go from drilling holes to carving shapes without breaking a sweat!

| Benefit | Details |

|---|---|

| Cost-Effectiveness | Fewer tools mean lower costs. |

| Versatility | Handles various tasks easily. |

How to Choose the Right Interchangeable Head for Your Milling Tool

Factors to consider: material, size, and design. Tips for matching heads to specific tasks.Choosing the right interchangeable head for your milling tool is important. Here are key factors to keep in mind:

- Material: Different materials work better for different tasks. Harder materials need durable heads.

- Size: Ensure the head fits your tool’s size. A good fit ensures safety and effectiveness.

- Design: The design can influence how well the head performs. A good design boosts precision and control.

For better results, match heads to specific tasks. For example, use a fine head for detailed work and a coarse head for rough surfaces. This way, your milling tool works best.

What to consider when selecting a head?

Consider the material, size, and design of the head you choose. This helps your tool perform better and last longer.

Installation and Maintenance of Milling Tool Heads

Stepbystep guide on replacing heads. Best practices for maintenance and care.Changing the heads on a milling tool is easy. Follow these steps for a smooth process:

- Gather your tools: a wrench and new heads.

- Turn off the milling tool and unplug it for safety.

- Loosen the old head using the wrench.

- Remove the old head carefully.

- Attach the new head and tighten it securely.

For maintenance, clean the heads after use. Check for any damage. Store them in a dry, safe place. This keeps them sharp and ready for work.

Why is regular maintenance important?

Regular maintenance can increase the life of the milling tool and improve performance. Keeping the heads in good shape helps avoid costly repairs.

Top Brands and Models of Milling Tools with Interchangeable Heads

Review of leading brands in the market. Recommendations based on user feedback and performance.Many brands make excellent milling tools with interchangeable heads. Some popular names include:

- DeWalt: Known for strength and durability.

- Makita: Users love its precision and ease of use.

- Bosch: Offers reliable performance and versatility.

- Milwaukee: Praised for its advanced features.

Feedback from users shows these brands excel in performance. Choosing one of them can make your projects easier and more fun.

What features should I look out for in these tools?

Look for durability, versatility, and ease of use. These features ensure you get the best value for your money and make your work smoother.

Common Applications of Milling Tools with Interchangeable Heads

Industries that benefit from these tools. Specific projects suitable for interchangeable heads.Milling tools with interchangeable heads are very useful in many industries. They help workers create precise shapes in metal, wood, and plastic. Here are some fields that benefit from these tools:

- Automotive: Used for making engine parts.

- Aerospace: Helps build lightweight airplane components.

- Construction: Ideal for shaping materials in projects.

Specific projects fit well with interchangeable heads. They can tackle tasks like:

- Machining custom parts.

- Creating detailed designs.

- Repairing old machinery.

Troubleshooting Common Issues with Milling Tools

Identification of frequent problems. Solutions to enhance performance and durability.Milling tools with interchangeable heads can face some common issues. You might notice poor cutting quality or wear and tear over time. Understanding these problems helps keep your tools working well. Here are some frequent issues and helpful solutions:

- Problem: Dull cutting edges.

- Solution: Regularly sharpen the heads for better performance.

- Problem: Vibration during use.

- Solution: Check for tight fittings and balance the tool.

- Problem: Chips and debris build-up.

- Solution: Clean the tool after every use to maintain durability.

What should I do if my tool is vibrating?

Make sure the head is tight and the tool is balanced. This reduces vibration and makes work smoother.

Why is my tool cutting poorly?

Dull edges cause poor cuts. Sharpening often helps restore cutting quality.

Future Trends in Milling Tool Technology

Innovations in interchangeable head designs. Predictions for advancements in milling technology.New ideas are coming to milling tools with interchangeable heads. These tools can now change heads easily to fit different jobs. Innovations allow for better shapes and sizes, making work faster and smarter.

Predictions show that future milling technology will focus on:

- Enhanced durability of materials

- Smart features for better control

- Environmental efficiency to reduce waste

In the future, these tools will help workers become even more skilled. A famous tool expert said, “Innovation in design is key to improving performance.”

What are the latest designs in interchangeable heads?

New designs offer quick changes and extra strength. This helps workers switch heads quickly and get more done.

What advancements can we expect in milling technology?

We expect smarter technology that talks to computers. This makes milling smoother and more stable. Better tools mean better work!

Conclusion

In conclusion, milling tools with interchangeable heads offer flexibility and efficiency. You can easily switch heads for different tasks. This saves time and money while improving your projects. We encourage you to explore these tools further. Check out videos or guides online to see how they work and choose the right one for your needs. Happy milling!FAQs

What Are The Advantages Of Using A Milling Tool With Interchangeable Heads Compared To Traditional Fixed-Head Milling Tools?Using a milling tool with interchangeable heads is much better than using fixed-head tools. First, you can change the heads for different jobs. This helps you do many things with one tool. It also saves money because you don’t need to buy many tools. Lastly, it’s easier to fix if something breaks, since you can just swap the head instead of getting a whole new tool.

How Do You Determine The Appropriate Interchangeable Head For A Specific Milling Operation?To choose the right interchangeable head for milling, you need to know what shape you’re making. First, check the material you will cut. Then, look at the size and type of cut required. Finally, match the head with the machine’s settings. This way, you’ll get the best results for your work!

What Materials Are Commonly Used For The Manufacturing Of Interchangeable Heads In Milling Tools, And How Do They Affect Tool Performance?Interchangeable heads in milling tools are often made from hard materials like carbide, steel, or ceramic. Carbide is very strong and cuts well, while steel is tough and can hold sharp edges. Ceramic can be super hard but might break easily. The material you choose affects how fast and smooth the tool works. Stronger materials help the tool last longer and do a better job.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Precision Of A Milling Tool With Interchangeable Heads?To keep your milling tool working well, you should clean it after each use. Make sure to check the heads for wear or damage. Always tighten the heads properly before starting. Store the tool in a dry place to prevent rust. Lastly, follow the manufacturer’s instructions for extra tips on care.

Are There Any Safety Considerations Or Best Practices To Keep In Mind When Changing Milling Heads During Operation?Yes, there are safety tips to follow when changing milling heads. Always turn off the machine first. This keeps you safe from moving parts. Wear safety glasses and gloves to protect yourself. Make sure the area is clean and clear of tools or materials. These steps help prevent accidents and keep you safe.